industrial manufacturing techniques

- continues process

- batch process

production of aspirin

ethyl ethanoate and aspirin are produced by a batch process in industry

in a chemical plant large quantities of reactants are brought together in a reactor during which time the product is produced

after a certain time the reactor is emptied and the product is separated from the reaction mixture and purified

the product is then dried and packaged

esters and their manufacture

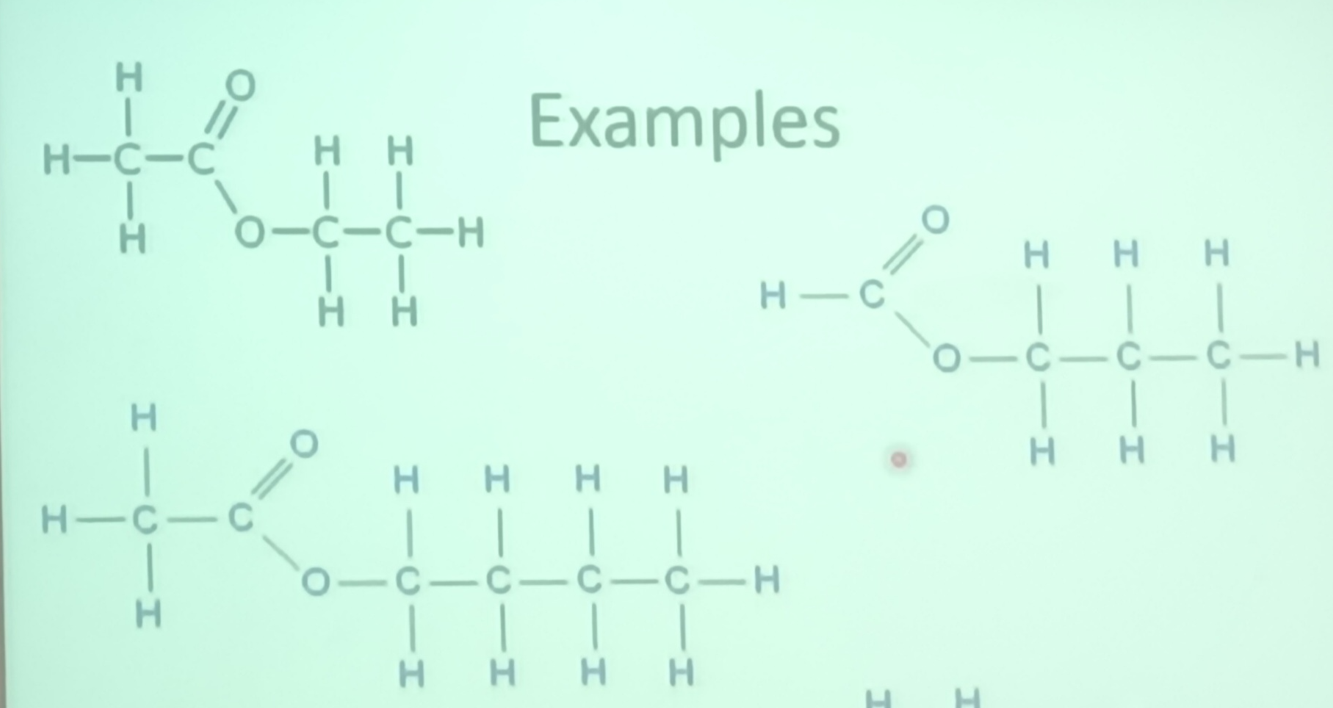

- these have the functional group -COO-

- they have the name -yl- anote eg methyl methoate

- both R groups form part of the same

esters

- esters are useful products

- used as solvents

- making polyesters

- fruit smells are due to the presence of esters

- ethyl ethanoate is used in glue and nail polish removers

- ethyl ethanoate is used to remove caffeine from tea and coffee

manufacture

- made by reacting ethanol with ethanoic acid

- concentrated sulfuric acid is used as a catalyst

- the reaction is slow and reversable

- CH₃CH₂OH + CH₃COOH → CH₃COOCH₂CH₃ + H₂O

- in industry the ester is made in a batch process

- ethanol and ethanoic acid are added to a large reaction vessel together with the catalyst

- the reaction mixture is heated

- water produced during the rection is removed by distillation

- yields of up to 95% are possible

- other methods

- Tishchenko reaction

- liquid phase oxidation of butane

- alkylation ethanoic acid with ethene (Avada process)

testing methods and techniques

- boiling point determination

- boiling point of pure substances are known very accurately and are listed in databases and books

- the purity of a sample can be determined by comparing the boiling point of the sample to the actual value

- boiling point occurs when the intermolecular bonds are broken

- the greater the difference the more impurities are present

- distillation can be used to determine boiling point

- all values for boiling points are given as standard temperature and pressure