2. Surfactants and self-assembly

Surface tension and surface active molecules- Interactions between the molecules on the surface give rise to surface tension.

• If the molecular composition is altered → the surface tension is changed

• Adsorption at the surface of surface active molecules

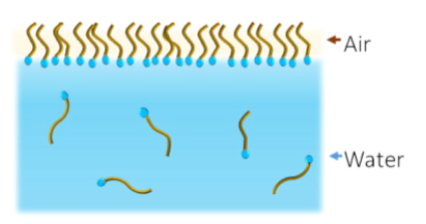

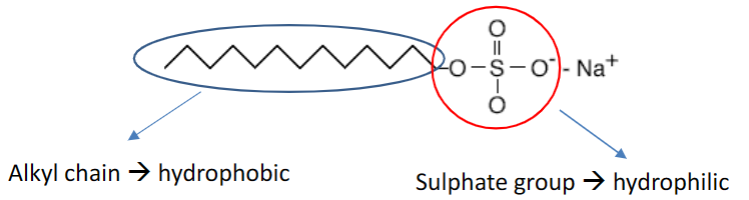

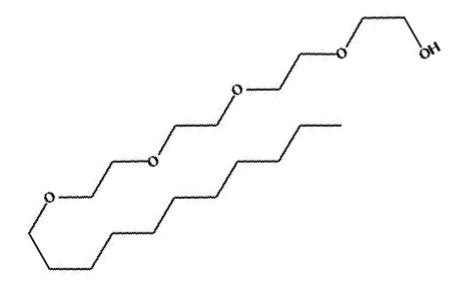

Surfactants - Molecules that interact with surfaces or interfaces . Surfactants are usually amphiphilic organic compounds, that have hydrophobic part (tail) and hydrophilic part (head). Surfactant= surface active agents

Example: sodium dodecyl sulfate (SDS) or fatty acid salts in common hand soap

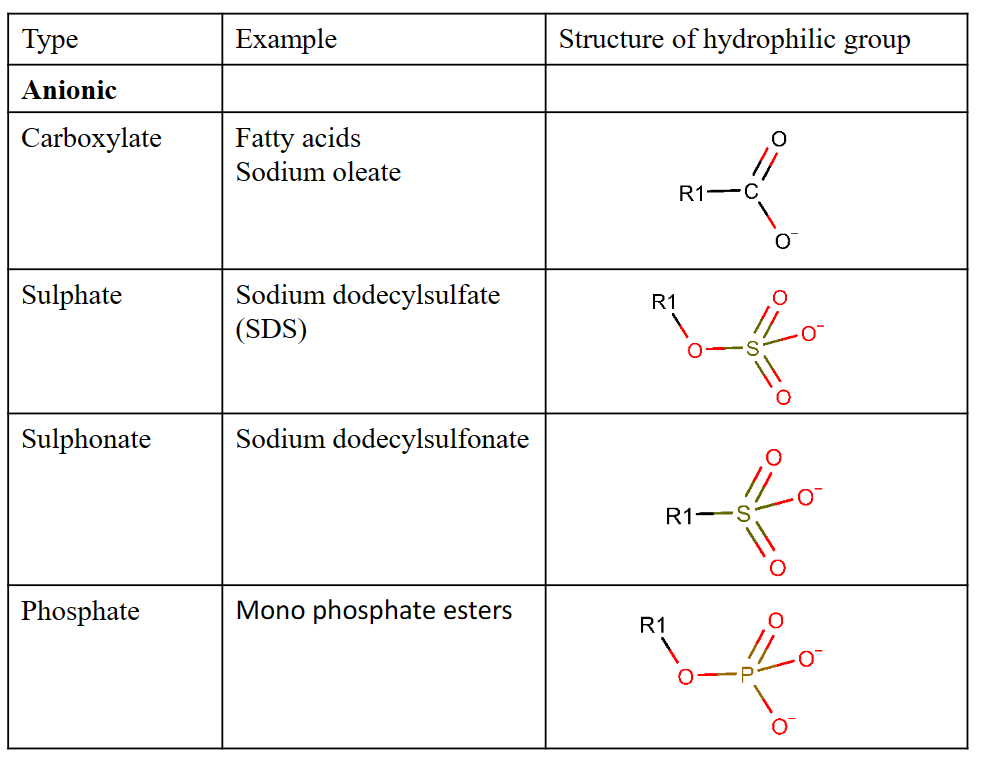

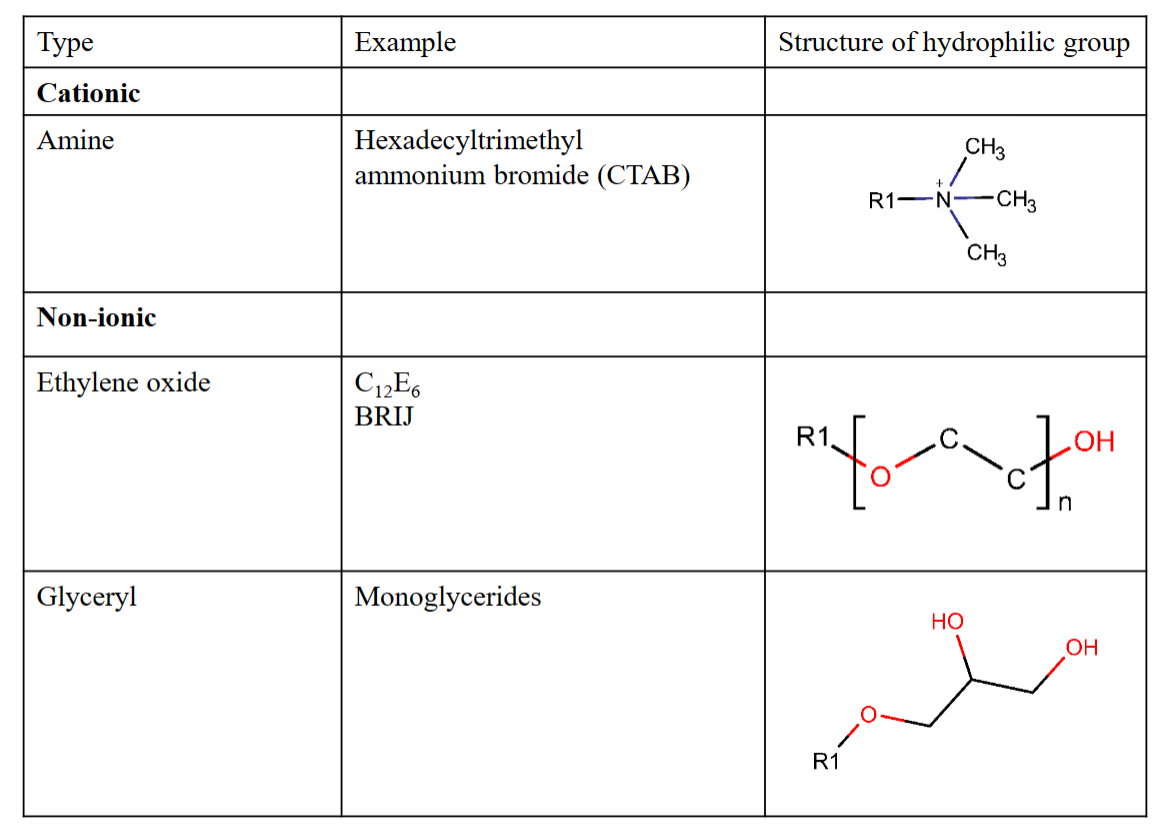

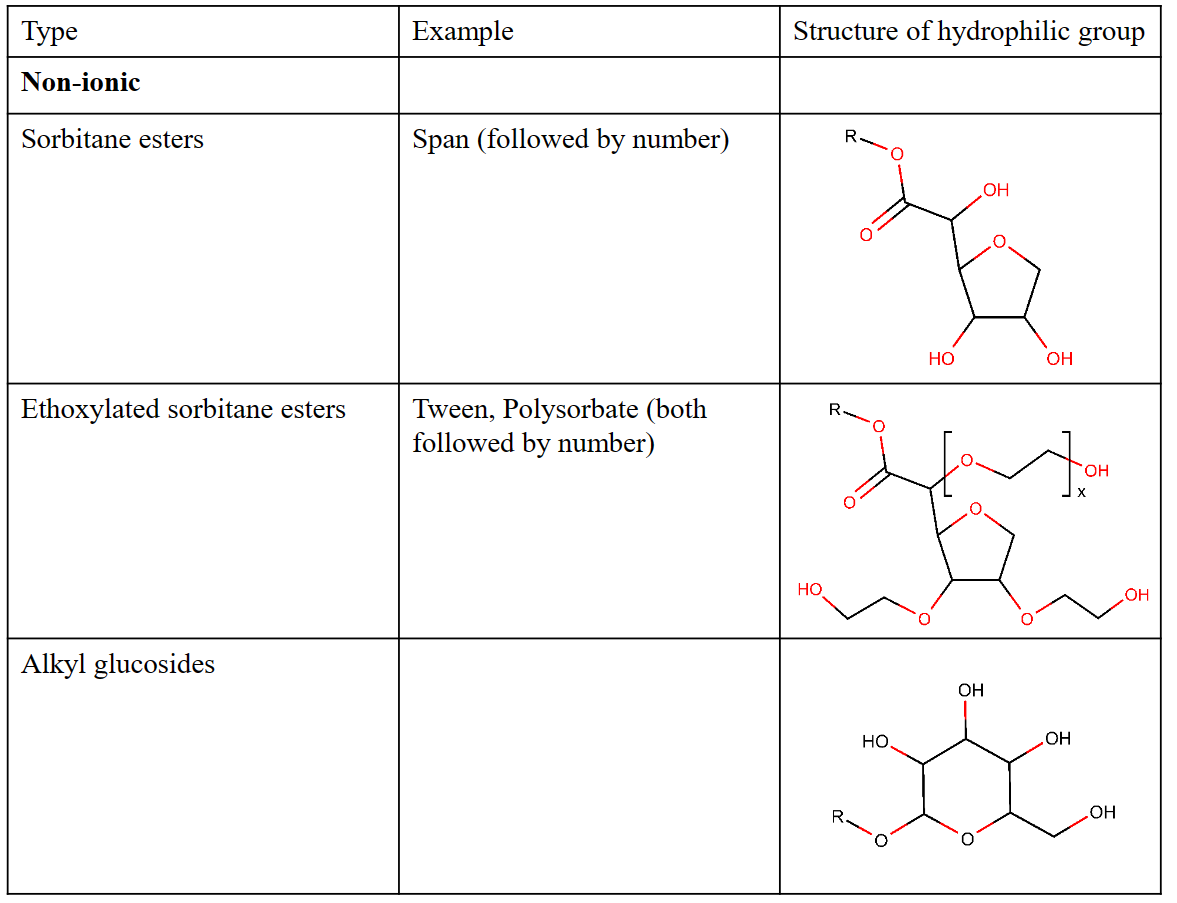

Some common types of polar head groups

The hydrophobic tail is typically one (sometimes two) hydrocarbon chain(s) of various length

Surfactants in aqueous solution

- The polar head groups are hydrated and take part in the H-bonding structure of water

- Hydrocarbon tails do not interact with water molecules.

– “Hydrophobic effect” (the segregation of water and nonpolar substances)

– Tail in solution → free energy increase

– Aggregation → minimize contact between hydrocarbon tails and water molecules

Surfactants can self-assemble

• Amphiphilicy – surfactants can form micelles and other structures

• Equilibrium structure - Thermodynamically stable

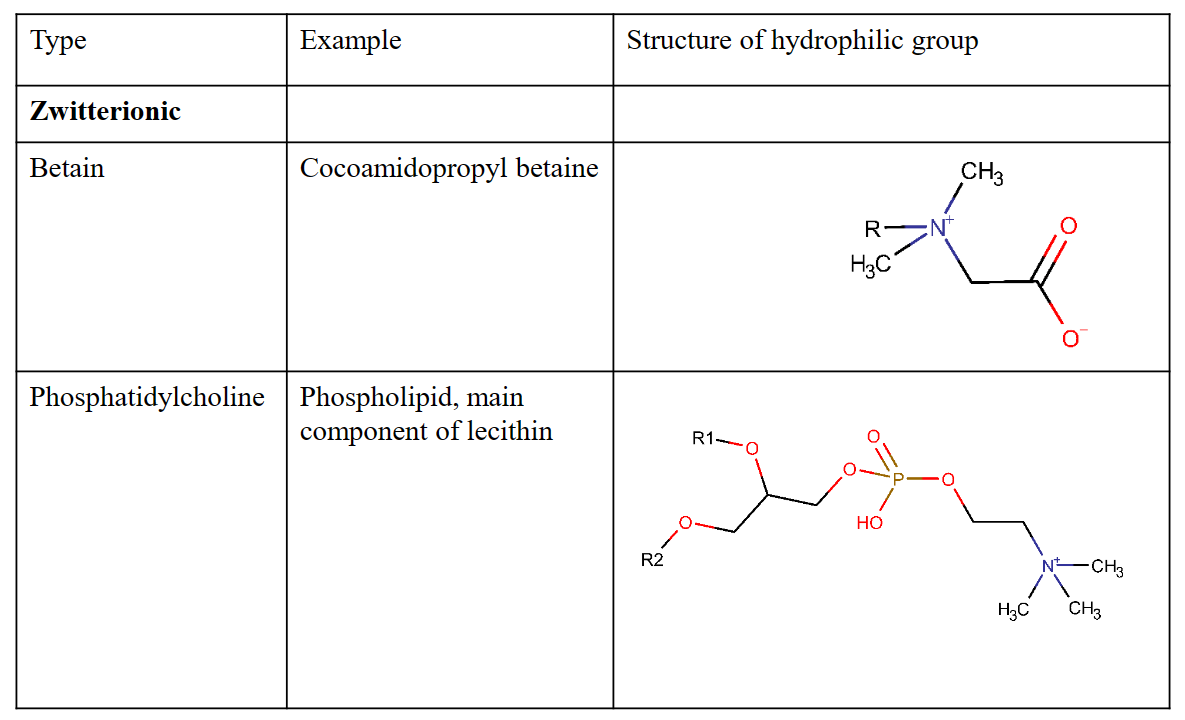

• Constant rapid exchange of individual molecules between solution and surfactants particles

Formation of micelles

- Micelles are self-assembled equilibrium structures

- Micellar solutions are not dispersions – they are one-phase solutions!

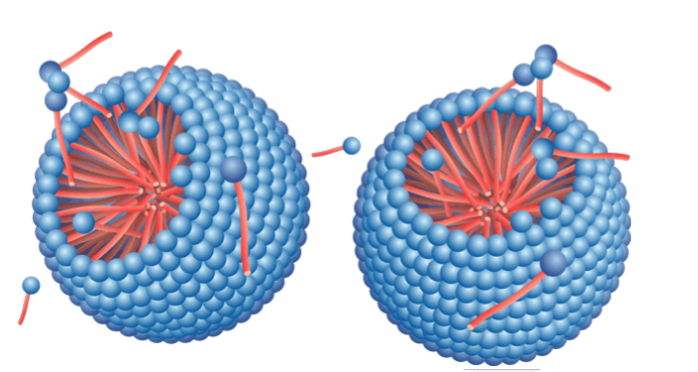

- Micelles form at the critical micelle concentration (CMC)

- Below CMC, only dissolved particles, no micelles

Micelle formation

• Micelle formation occurs as a result of interaction parameters and gives an increase in entropy.

• The standard free energy (ΔG= ΔH-TΔS) is affected by:

– Decrease

• Removal of non-polar chains from the aqueous phase.

– Increase

• Interface creation

• Repulsion between hydrophilic head groups.

• Repulsion between head groups counteracts micelle formation

– Steric (e.g large head groups → problem with packing)

– Electrostatic

A large hydrophilic group (how long carbon chain is) gives a high CMC

A large hydrophobic group gives a low CMC

Mixed micelles

• Micelles can consist of different types of surfactants

• Non-surfactant molecules can be accommodated in micelles

– Example: fatty alcohol in fatty acid micelle (breaks up repulsion between acid groups)

• Can influence the CMC

– Example: Less repulsion between polar head groups

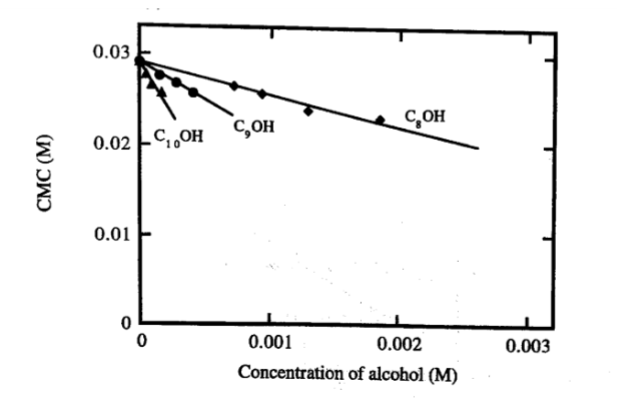

Decrease in CMC for potassium octanoate upon addition of fatty alcohols

• Decrease depends on alkyl chain length

• Decrease is practically linear with alcohol concentration

Functional properties of surfactants determined by CMC- Most functional properties of surfactants are determined by the CMC

- Washing – detergency

- Foaming

- Emulsification

- Solubilization of hydrophobic compounds

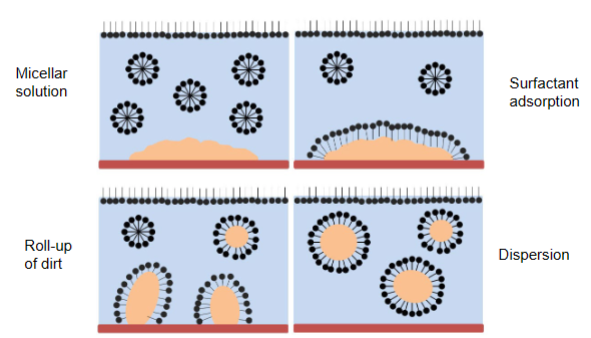

Detergency

- Micellar solution- Above CMC

- Surfactant adsorb to the dirt

- Roll-up of dirt

Can either occur:

- Spontaneously

- Mechanical force (rubing etc) - most common

- Dispersion (Dirt inside micelle)

Micelle formation- Micelles are dynamic, short lifespan meaning that reform equally fast. They are equilibrium surfactant unimers (individual molecules). They interact with the solvent through the hydrophilic surface and have a hydrophobic inner domain.

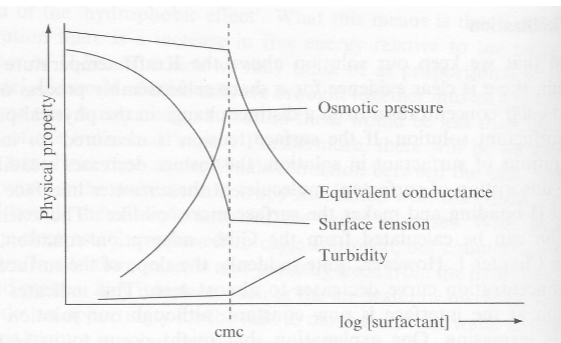

Physical properties change at the CMC

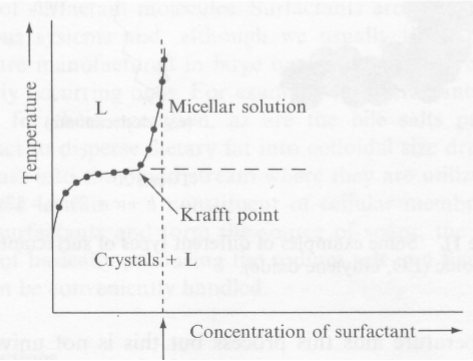

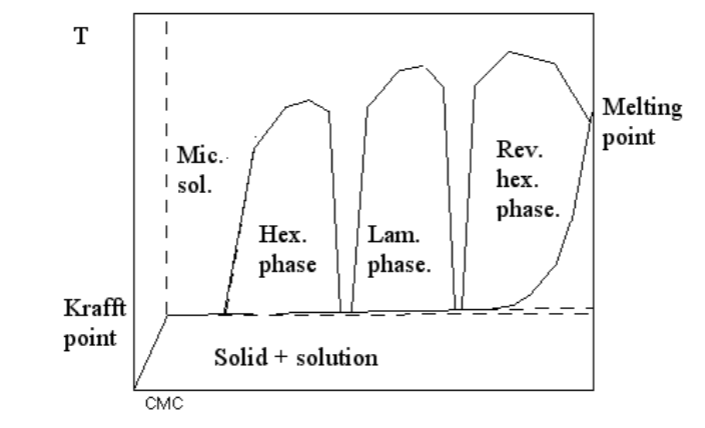

Krafft point- The Krafft point is the temperature surfactant solubility increases drastically.

- Below Krafft temperature is the solubility of the surfactant is low and micelles can not be formed.

- It is a typical property for ionic surfactants.

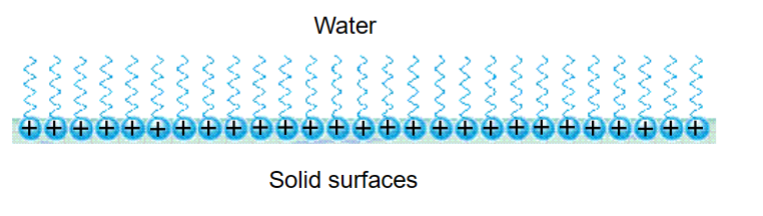

Wetting- The ability of a liquid to maintain contact with a solid surface. Adsorption of surfactants changes the properties of the surface

Clean glass: High energy surface – often slightly anionic

Water on a surfactant monolayer of hexadecyltrimethylammonium bromide (cationic):

Low energy surface

No wetting of surface by water

Adsorption of surfactants

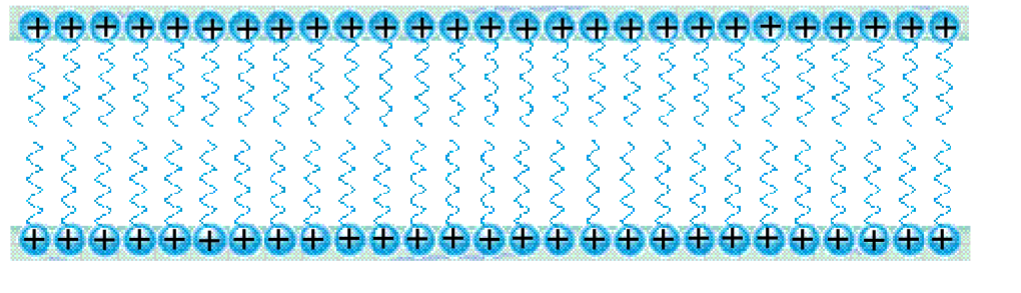

• Wetting can be restored by increasing the surfactant concentration to the CMC.

– Bilayer formation.

Wetting phenomena and surfactants in applications

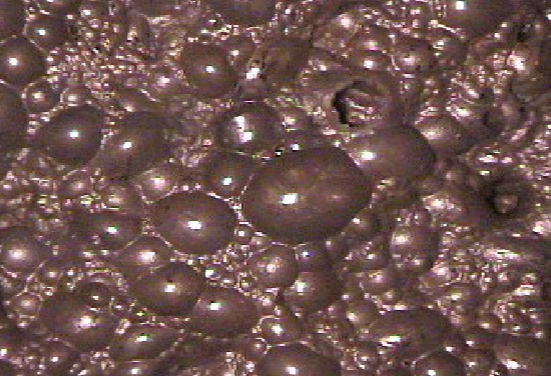

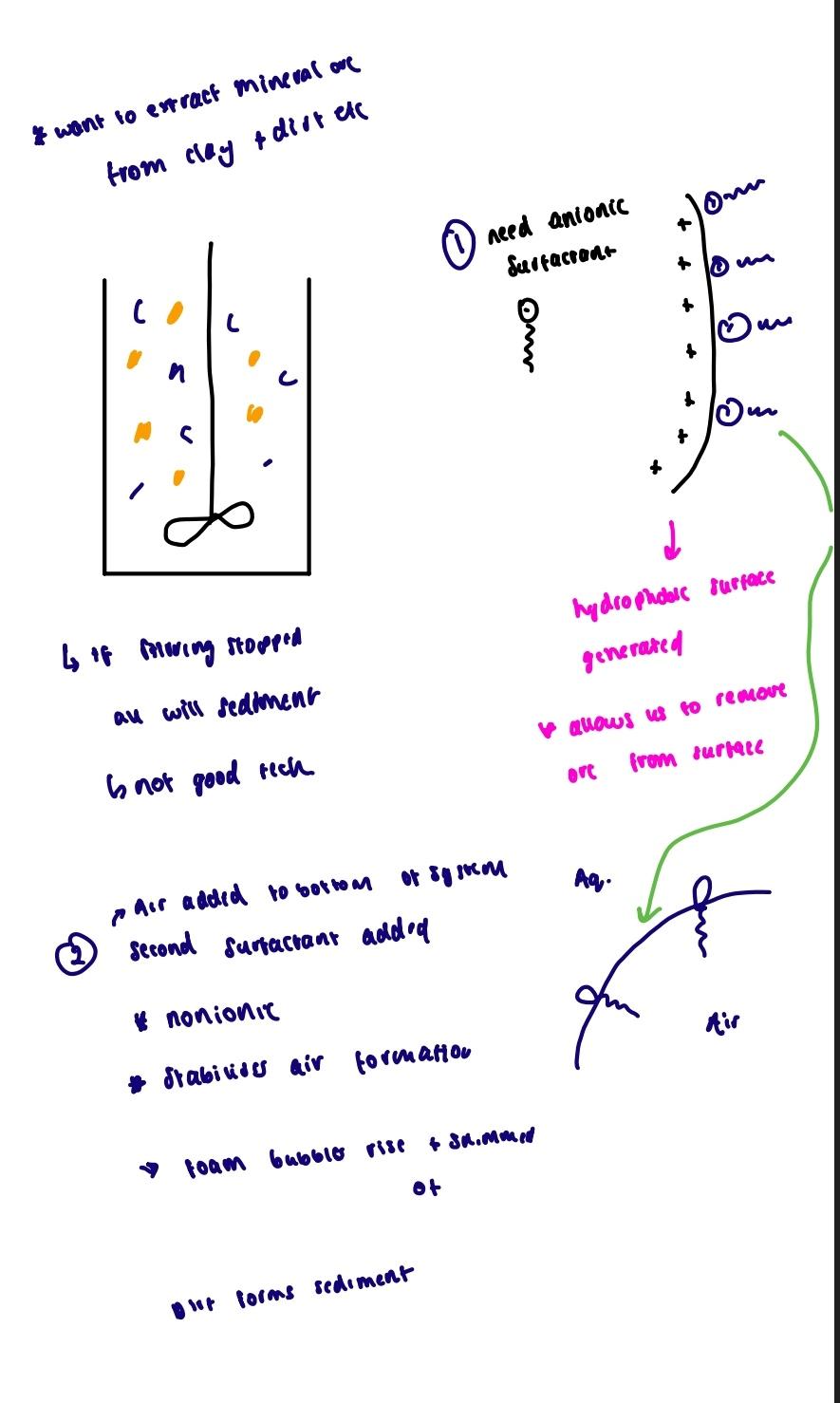

Mineral ore flotation

Want to extract mineral ore from clay and dirt etc.

- Anionic surfactants

Hydrophobic surface generated which allos us to remove ore from surface

- Air is added to the bottom of system and second non-ionic surfactant is added

The surfactants stabilize air formation and foam bubbles rise and dirt forms sediment

Surfactant self-assembly

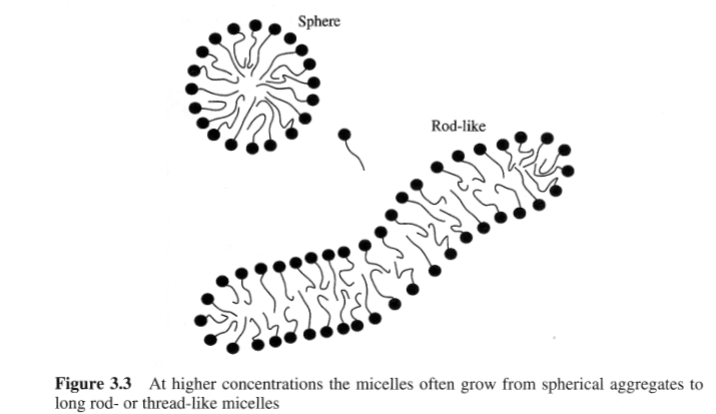

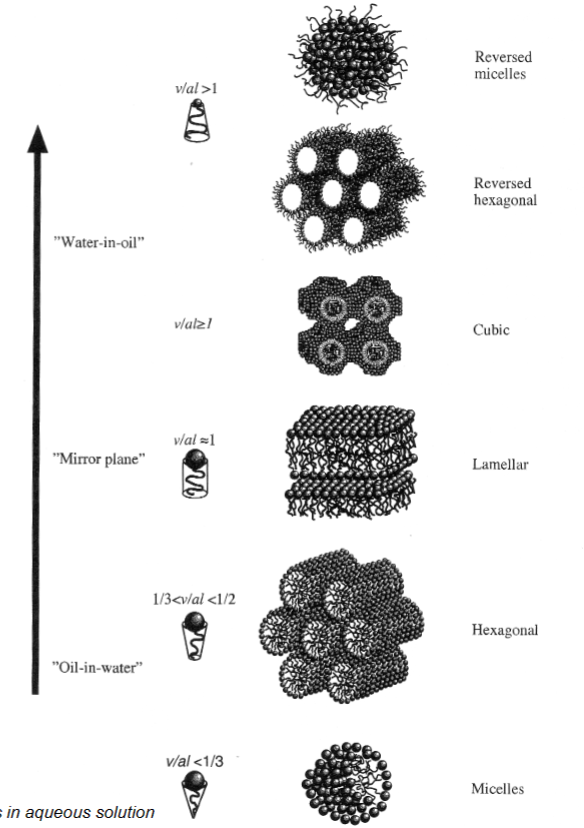

• Concentration above CMC additional self-assembled structures start to form (affects viscosity)

Reversed hexagonal:

- Water inside

Hexagonal:

- Water is in between tubes

- Inside is hydrophobic

Surfactant phase behavoiur

Detergents are a mixture of ionic and non-ionic surfactant

- Low temperature is good ethoxylated surfactants → no Krafft point, low CMC

- High temperature is required for ionic surfactants

Typical phase diagram for an ionic surfactant

- Between phases, it be can different types of sub-phase

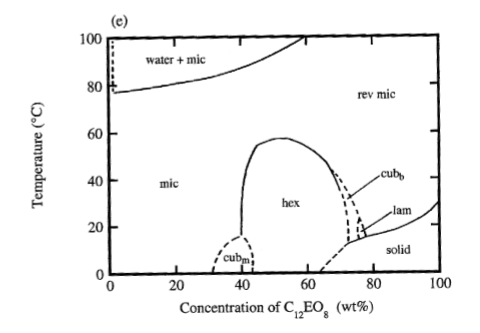

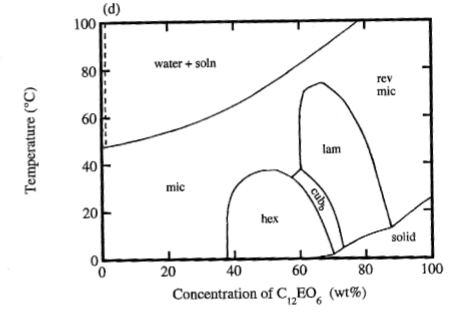

Ethoxylated surfactants

- Strong temperature dependence (good at low temperatures)

- Above the Krafft point, temperature does not influence phase behaviour greatly

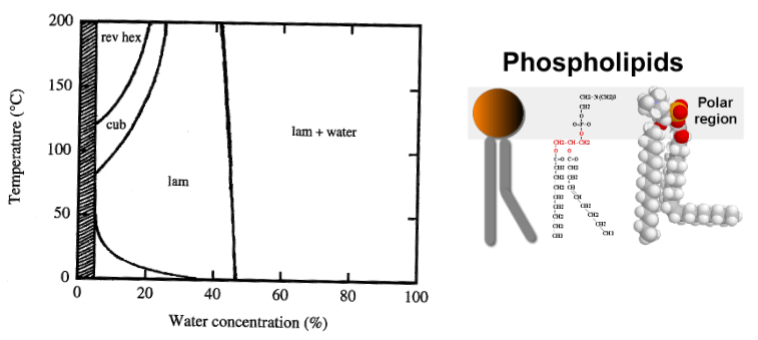

Lecithin-water

No Krafft point → amorphous so don’t form crystallised structures

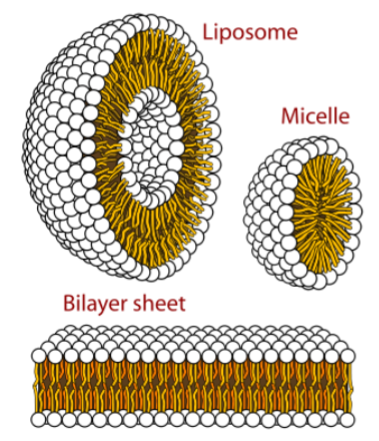

Lamellar phase and vesicles (liposomes)

Examples of liposomes

Polymer prevents unwanted interaction

Ligands used to direct the drug

Examples of self-assembled surfactant (polar lipid) structures for drug delivery

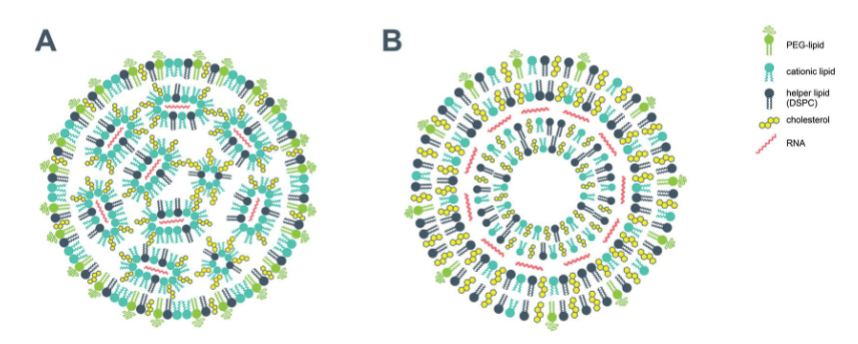

RNA-based vaccines for COVID-19

Highly schematic

B) Cationic surfactant: it will not be charged in tissue, charged and de-charged

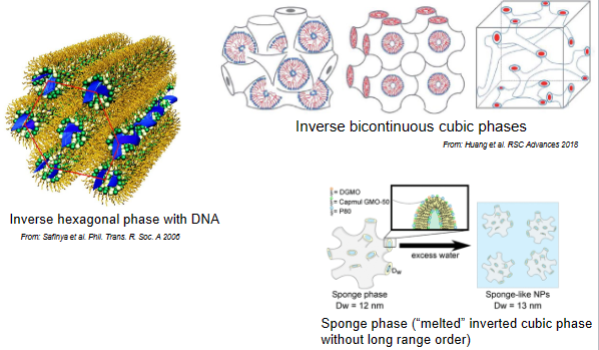

Examples of self-assembled inverse architectures for encapsulation/drug delivery

Encapsulating for example enzyme

Sponge phase: channels are not straight, instead curvy. For example slow release

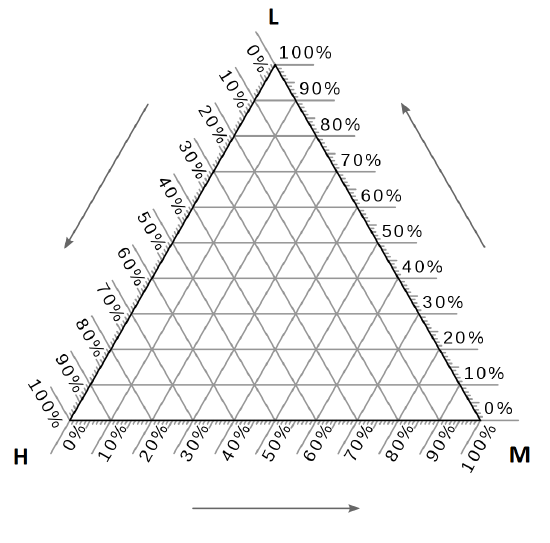

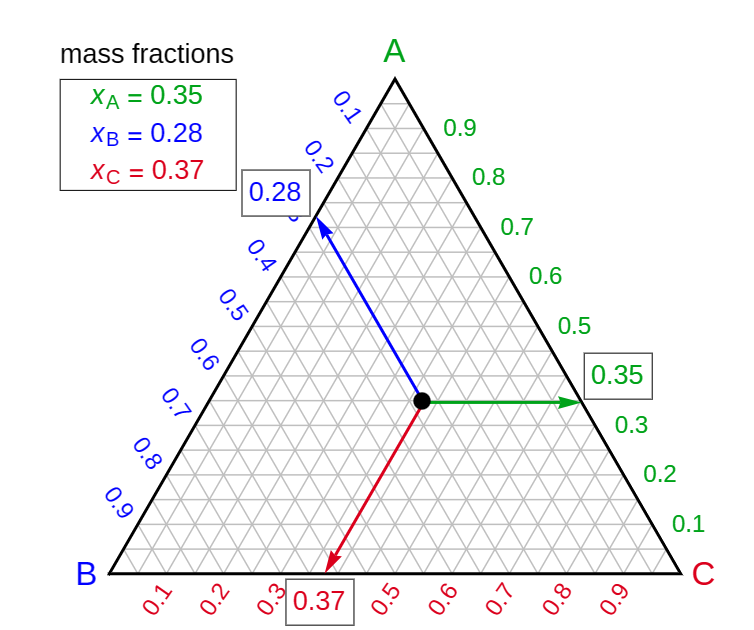

Ternary phase diagram- Three component system.

- Every corner represents a pure condition

- Each side of the triangle represents all possible binary combinations of the three components. On any of those sides, the fraction of the third component is zero (0%).

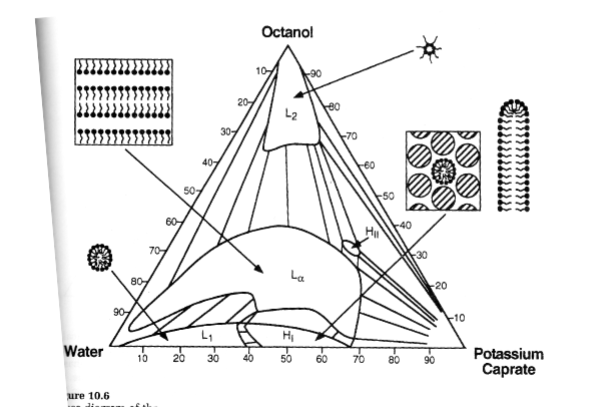

Ternary phase diagrams for surfactants

L1=miceller phase

Lα=lameller phase

Octanol is the corresponding alcohol to surfactant (potassium caprate)

Non-ionic ethoxylated surfactants- Increasing temperature leads to two phases. This is an exception.

Cloud point temperature at which a surfactant solution leads to a two phase transition, typically from a clear solution to a cloudy state due to phase separation (the point where precipitation starts).

- Functionality lost above cloud point (solubility is lost)

- Balancing of hydrophobic effects and head-group hydration (temperture might influence orientation of hydrophobic chain → making it less hydrophobic)

- Very low Krafft point (not relevant for applications) - we consider it not be have a Krafft point

Applications of anionic surfactants- Used in soaps, detergents and as stabilizers.

- Form stable films (good foaming agents)

- Sensitive to high ionic strengths (since they are charged)

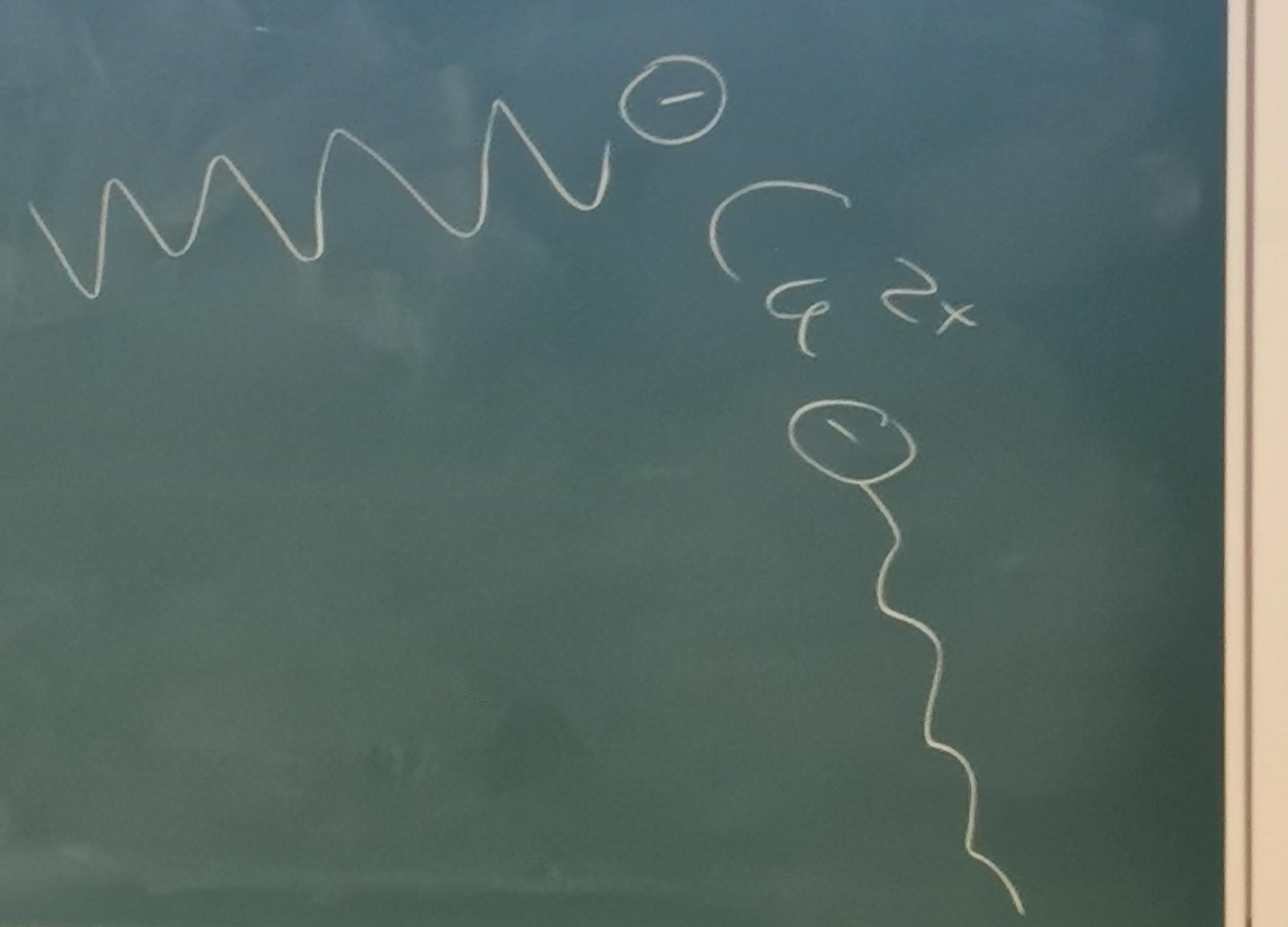

- Sulphate/Sulphonate surfactants are less sensitive to Ca2+ than the fatty acids are. If we have hard water it will be less sufficient, forming an insoluble salt of calcium ions and two surfactants

- However, irritant to the skin.

- ”Bath tub ring”

Applications of cationic surfactants-

- Cationic surfactants interact strongly with biological membranes → toxic.

– Pesticides and bactericides

- Mineral ore flotation

- Asphalt – (positive charged bitumen emulsions and negative gravel)

- Hair conditioners – reducing static electricity and frizziness (hair is negatively charged → frizzy)

- Anti-caking agents – preventing liquid bridges in powders through water-wetting prevention (make cationic → hydrophobic)

- Anti-corrosion agents – preventing water wetting of steel surfaces

- Drug delivery/gene therapy – form complexes with anionic macromolecules

Applications of nonionic surfactants- As stabilizers in many applications

- Less sensitive to high ionic strength and pH

- Less efficient at high T

- Often efficient at lower T (compared to anionic surfactants)

- Form less rigid films than ionic surfactants (lack of electrostatic repulsion)

- Useful for low foaming applications.

Applications of zwitterionic surfactants

– Betain

• Low irritant on skin

• Personal-care products

– Schampoos

– Phospholipids – ”lecithin”

• Biological material

• Food and Pharmaceutical applications

Environmental issues

• Came to attention in the 1960s and 1970s.

• Some surfactants are slowly degraded.

• High toxicity for aquatic organisms.

– Ex. ethoxylated nonyl and octyl phenols (Triton).

– To decrease toxicity the apolar chain was changed to linear.

Aerosol OT ( try to remove release of oil in sea) → sank to the bottom of sea

• Increase biodegradability:

– Introduction of cleavable surfactants (ester linkage etc.) between head and tail- tend to hydrolysis (not so stable)

• Increased interest in surfactants from renewable resources.

– Alkyl glucosides to substitute ethoxylated surfactants