Week 5: Understanding Process Types in Manufacturing and Services

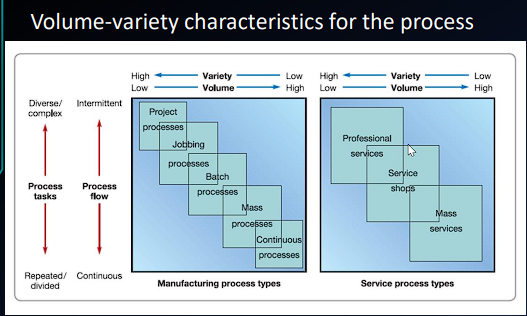

Overview: This diagram categorizes manufacturing and service processes based on their volume and variety characteristics, showcasing how different processes align with the scale of production and the diversity of outputs.

Project Processes: High variety and low volume, suitable for complex, unique productions like large construction projects.

Jobbing Processes: Moderate variety and volume, appropriate for customized jobs requiring specific skills and setups.

Batch Processes: Moderate to low variety and higher volume, used for producing goods in batches, allowing for economies of scale without high standardization.

Mass Processes: Low variety but high volume, ideal for standardized products produced continuously.

Continuous Processes: The highest volume with very low variety, optimal for industries like chemicals and steel where the process does not stop.

Professional Services: High variety and low volume, tailored to individual client needs, such as consulting or legal services.

Service Shops: Moderate variety and volume, such as restaurants and smaller clinics, offering more standardized services to a larger group.

Mass Services: Low variety and high volume, including services like public transportation and retail banking, which serve large numbers of customers with standardized services.

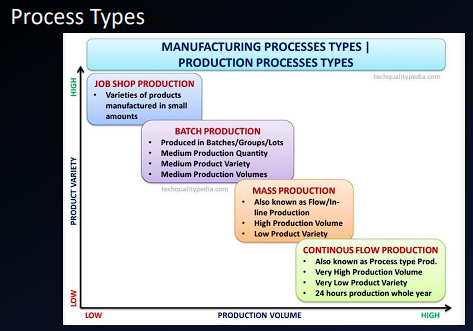

Characterized by a high variety of products manufactured in small quantities, often requiring unique setups and significant flexibility.

Involves the production of goods in batches or groups, allowing for a moderate variety and quantity, balancing flexibility and efficiency.

Also known as flow or line production, it is characterized by high production volumes of low-variety products, optimizing efficiency and consistency.

Represents the most extreme form of mass production, designed for the unintermittent production of goods, often in industries requiring 24/7 operation like oil refining and electricity generation.

Process Selection: Understanding these characteristics is crucial for businesses to choose the most appropriate manufacturing or service process based on their operational goals and market demands.

Strategic Fit: Each process type has different implications for capital investment, labor skills, and operational flexibility, influencing strategic decisions in capacity planning and supply chain management.

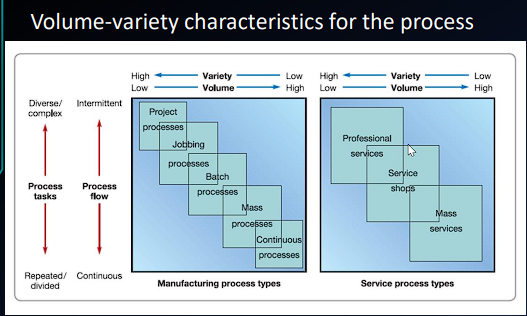

Overview: This diagram categorizes manufacturing and service processes based on their volume and variety characteristics, showcasing how different processes align with the scale of production and the diversity of outputs.

Project Processes: High variety and low volume, suitable for complex, unique productions like large construction projects.

Jobbing Processes: Moderate variety and volume, appropriate for customized jobs requiring specific skills and setups.

Batch Processes: Moderate to low variety and higher volume, used for producing goods in batches, allowing for economies of scale without high standardization.

Mass Processes: Low variety but high volume, ideal for standardized products produced continuously.

Continuous Processes: The highest volume with very low variety, optimal for industries like chemicals and steel where the process does not stop.

Professional Services: High variety and low volume, tailored to individual client needs, such as consulting or legal services.

Service Shops: Moderate variety and volume, such as restaurants and smaller clinics, offering more standardized services to a larger group.

Mass Services: Low variety and high volume, including services like public transportation and retail banking, which serve large numbers of customers with standardized services.

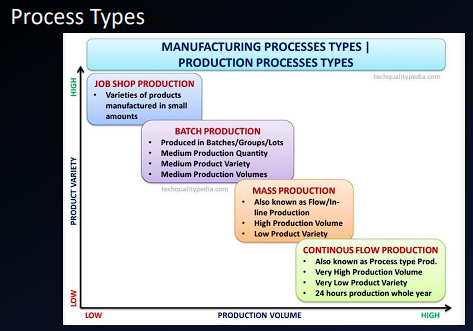

Characterized by a high variety of products manufactured in small quantities, often requiring unique setups and significant flexibility.

Involves the production of goods in batches or groups, allowing for a moderate variety and quantity, balancing flexibility and efficiency.

Also known as flow or line production, it is characterized by high production volumes of low-variety products, optimizing efficiency and consistency.

Represents the most extreme form of mass production, designed for the unintermittent production of goods, often in industries requiring 24/7 operation like oil refining and electricity generation.

Process Selection: Understanding these characteristics is crucial for businesses to choose the most appropriate manufacturing or service process based on their operational goals and market demands.

Strategic Fit: Each process type has different implications for capital investment, labor skills, and operational flexibility, influencing strategic decisions in capacity planning and supply chain management.