Science 10 Notes (2nd Quarter)

Recap last lesson:

Introduction to Electricity and Magnetism

Electricity and magnetism are closely related fundamental forces of nature. Electricity refers to the flow of electric charge, while magnetism is the property of certain materials to attract or repel each other. The study of electricity and magnetism is called electromagnetism. Benjamin Franklin's experiments with lightning and invention of the lightning rod contributed to understanding electricity. Alessandro Volta's invention of the battery led to the development of electrical circuits and the study of electric current. Michael Faraday's experiments established the relationship between electricity and magnetism, showing that a changing magnetic field can induce an electric current. James Clerk Maxwell's equations unified the theories of electricity and magnetism, leading to the understanding of electromagnetic waves. The practical applications of electricity and magnetism include power generation, electric motors, and telecommunication. The study of electricity and magnetism is foundational in modern physics and essential in various fields of science and technology.

key concepts on history:

Michael Faraday and Joseph Henry discovered separately that electricity can be generated by moving a magnet through a coil. According to Faraday’s Law of Induction “A changing magnetic field induces an electric field. A changing electric field induces a magnetic field”.

Electricity can be generated by the movement of a magnet through a coil. The changing magnetic field produces an electric field which produces a potential difference to generate electricity.

Electromagnetic induction is the process of generating an electric current in a conductor by changing the magnetic field around it. It was discovered by Michael Faraday in the early 19th century. Faraday observed that when a magnet is moved near a conductor or when the magnetic field through a conductor changes, an electric current is induced in the conductor. This discovery laid the foundation for the development of electric generators and transformers, which are essential in modern power systems. Faraday's work on electromagnetic induction revolutionized the field of electromagnetism and paved the way for numerous technological advancements.

Electromagnetism and Electromagnet Induction

Electromagnetism:

Electromagnetism is the branch of physics that deals with the interaction between electric currents and magnetic fields.

It is described by Maxwell's equations, which unify electric and magnetic phenomena.

Electromagnetic waves, such as light, are a result of changing electric and magnetic fields.

Electromagnetism is fundamental to many technological applications, including motors, generators, and telecommunications.

Electromagnetic Induction:

Electromagnetic induction is the process of generating an electric current in a conductor by changing the magnetic field around it.

It is based on Faraday's law of electromagnetic induction.

Induced current is proportional to the rate of change of magnetic flux through the conductor.

Applications of electromagnetic induction include transformers, electric generators, and induction cooktops.

FAQS

Q1. Define Electromagnetic Induction.

Electromagnetic Induction is a current produced because of voltage production (electromotive force) due to a changing magnetic field.

Q2. Who discovered Electromagnetic Induction?

Electromagnetic Induction was discovered by Michael Faraday in 1831.

Q3. What is the significance of Electromagnetic Induction?

The significance of this discovery is a way of producing electrical energy in a circuit by using magnetic fields and not just batteries.

Q4. Which machines work on the principle of Electromagnetic Induction?

Everyday machines like motors, generators and transformers work on the principle of electromagnetic induction.

Q5. What are the applications of Electromagnetic Induction?

AC generators work on the principle of electromagnetic induction.

The working of electrical transformers are based on electromagnetic induction.

The magnetic flow meter is based on electromagnetic induction.

Explaining the Operation of a Simple Electric Motor and Generator

Electric Motor

Parts of Motor

Stator: The stationary part of the motor that contains the coils of wire.

Rotor: The rotating part of the motor that is connected to the shaft.

Shaft: The component that transfers the mechanical energy from the motor to the external device.

Coils: Wires wound around the stator that create a magnetic field when an electric current passes through them.

Magnets: Permanent magnets or electromagnets that generate a magnetic field to interact with the stator's magnetic field.

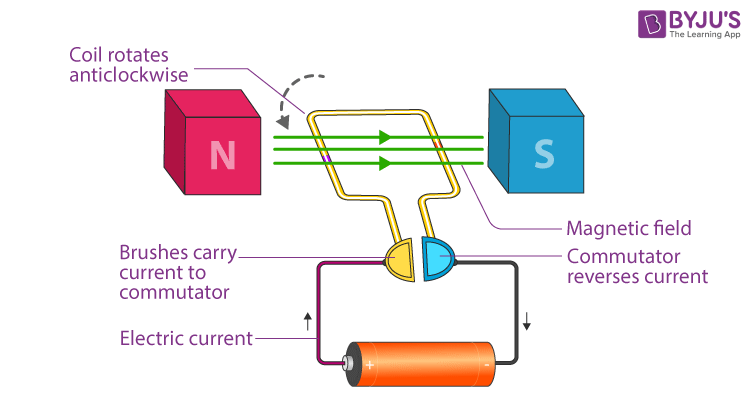

Brushes: Conductive contacts that deliver electric current to the rotor.

Commutator: A split ring that reverses the direction of the current flowing through the rotor's coils.

Working of Electric Motor

Electromagnetic Induction: When an electric current flows through the coils in the stator, it creates a magnetic field.

Interaction of Magnetic Fields: The magnetic field generated by the stator interacts with the magnetic field of the rotor, causing it to rotate.

Brushes and Commutator: As the rotor spins, the brushes and commutator ensure that the current flowing through the rotor's coils changes direction at the right time, maintaining the rotation.

Continuous Rotation: The continuous reversal of the current in the rotor's coils keeps the rotor spinning, converting electrical energy into mechanical energy.

Uses of Electric Motor

Industrial Applications: Electric motors are widely used in various industries for powering machinery, pumps, fans, and conveyor systems.

Transportation: Electric motors are used in electric vehicles, trains, and ships for propulsion.

Household Appliances: Motors are found in appliances like washing machines, refrigerators, air conditioners, and vacuum cleaners.

Power Tools: Electric motors are used in power tools such as drills, saws, and grinders.

Robotics: Motors are essential components in robotic systems, enabling movement and manipulation.

Medical Equipment: Electric motors are used in medical devices like MRI machines, ventilators, and surgical tools.

Note: The efficiency and performance of electric motors can vary depending on factors like design, size, and power source.

FAQS

Q1. Define Electric Motor.

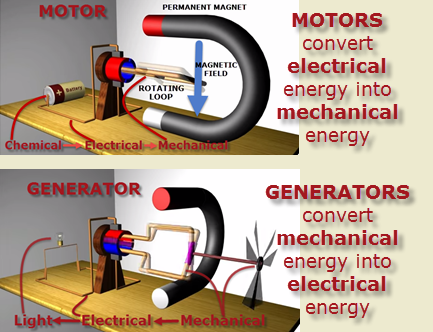

An electric motor is a machine that converts electrical energy to mechanical energy.

Q2. Define Electric Generator.

An electric generator is a machine that converts mechanical energy to electrical energy.

Q3. Which rule is followed by Electric Motor?

Electric motor follows Fleming’s left-hand rule.

Q4. Which rule is followed by the Electric Generator?

Electric motor follows Fleming’s right-hand rule.

Step by Step Process of How an Electric Motor Works

Introduction

An electric motor is a device that converts electrical energy into mechanical energy.

It operates on the principle of electromagnetic induction.

Components of an Electric Motor

Stator: The stationary part of the motor that contains the coils of wire.

Rotor: The rotating part of the motor that carries the armature.

Armature: The core of the rotor that consists of wire windings.

Working Principle

When an electric current flows through the wire windings of the armature, a magnetic field is created.

The interaction between the magnetic field of the armature and the magnetic field of the stator causes the rotor to rotate.

Step-by-Step Process

Power Supply: The motor is connected to a power source, typically an electrical outlet or battery.

Current Flow: When the power is turned on, an electric current flows through the wire windings of the armature.

Magnetic Field: The electric current creates a magnetic field around the armature.

Interaction: The magnetic field of the armature interacts with the magnetic field of the stator.

Force Generation: The interaction between the magnetic fields generates a force that causes the rotor to rotate.

Continuous Rotation: As long as the current flows and the magnetic fields interact, the rotor continues to rotate.

Control: The speed and direction of the motor can be controlled by adjusting the current flow or changing the polarity of the magnetic fields.

Applications

Electric motors are used in various applications, including appliances, vehicles, industrial machinery, and robotics.

They provide the necessary mechanical power for tasks such as spinning fans, driving conveyor belts, propelling vehicles, and operating pumps.

Advantages

Electric motors are efficient, reliable, and have a high power-to-weight ratio.

They produce less noise and vibration compared to other types of motors.

Electric motors can be easily controlled and offer precise speed and torque control.

An electric motor is a device that converts electrical energy into mechanical energy, allowing it to perform work.

The basic principle behind the working of an electric motor is electromagnetic induction.

The motor consists of a coil of wire, called the armature, which is placed between two magnets.

When an electric current is passed through the armature, it creates a magnetic field around the coil.

The magnetic field interacts with the magnetic field of the permanent magnets, causing a force to be exerted on the armature.

This force causes the armature to rotate, resulting in the mechanical motion of the motor.

To keep the rotation continuous, a commutator is used. The commutator is a split ring that reverses the direction of the current flowing through the armature coil every half turn.

As the current direction changes, the magnetic field also changes, causing the armature to continue rotating in the same direction.

The rotation of the armature can be used to drive various mechanical devices, such as fans, pumps, or wheels.

The speed of the motor can be controlled by adjusting the amount of current flowing through the armature or by changing the strength of the magnetic field.

Electric motors are widely used in various applications, from household appliances to industrial machinery, due to their efficiency, reliability, and ease of control.

Introduction to Electric Motors

Electric motors are devices that convert electrical energy into mechanical energy. They are widely used in various applications, ranging from household appliances to industrial machinery. Understanding how electric motors work is essential for anyone interested in the field of electrical engineering. In this article, we will explore the basic components and steps involved in the operation of an electric motor.

Components of an Electric Motor

An electric motor consists of several key components that work together to produce rotational motion. These components include:

Stator: The stator is the stationary part of the electric motor. It is typically made up of a series of electromagnets that are arranged in a circular pattern. The stator's main function is to create a magnetic field that interacts with the rotor to generate motion.

Rotor: The rotor is the rotating part of the electric motor. It is usually made up of a shaft and a set of windings or permanent magnets. When an electric current is passed through the windings, a magnetic field is created, which interacts with the stator's magnetic field to produce torque and rotational motion.

Commutator: In motors that use brushes, the commutator is a crucial component. It is a cylindrical structure made up of copper segments that are insulated from each other. The commutator helps to reverse the direction of the current flowing through the rotor windings, ensuring continuous rotation.

Brushes: Brushes are conductive contacts that make electrical contact with the commutator. They supply current to the rotor windings and also help to reverse the direction of the current as the rotor turns. Brushes need to be replaced periodically as they wear down due to friction.

Bearings: Bearings are used to support the rotor shaft and allow it to rotate smoothly. They reduce friction and enable the motor to operate efficiently. There are different types of bearings used in electric motors, such as ball bearings and sleeve bearings.

Housing: The housing, also known as the frame, encloses and protects the internal components of the electric motor. It is usually made of a durable material such as metal or plastic. The housing also helps to dissipate heat generated during motor operation.

Cooling system: Electric motors generate heat during operation, and a cooling system is necessary to prevent overheating. This can be achieved through various methods, such as air cooling with fans or liquid cooling with coolant circulated through the motor.

Control circuitry: Electric motors often require control circuitry to regulate their speed, direction, and other parameters. This circuitry can include switches, relays, and electronic components that control the flow of electricity to the motor.

In conclusion, an electric motor consists of various components that work together to convert electrical energy into rotational motion. Each component plays a vital role in the motor's operation, from generating magnetic fields to supporting the rotating shaft and controlling its performance. Understanding these components is essential for designing, maintaining, and troubleshooting electric motors.

Electric Generator

A generator converts mechanical energy into electrical energy. It is used when there is no access to an electrical grid or during power outages. Generators work through electromagnetic induction, where a rotor spins within a magnetic field, creating an electric current. They can be powered by various sources such as gasoline, diesel, natural gas, wind, or water. There are different types of generators: portable generators for temporary use, standby generators for automatic power during outages, inverter generators for quiet and clean power, and industrial generators for large-scale operations. When choosing a generator, consider the power output and fuel type.

An example of an electric generator is a wind turbine. It converts the kinetic energy of the wind into electrical energy. As the wind blows, it causes the turbine blades to rotate. This rotation spins a magnet inside a coil of wire, creating an electric current. The generated electricity can then be used to power homes, businesses, or other electrical devices.

An electric generator works through the following steps:

Mechanical Energy Input: A source of mechanical energy, such as a turbine or an engine, is used to rotate the rotor of the generator.

Magnetic Field Generation: The rotor contains a set of electromagnets or permanent magnets. As it rotates, it creates a changing magnetic field.

Induction of Electric Current: The changing magnetic field induces an electric current in the stationary part of the generator, known as the stator. This is achieved through the principle of electromagnetic induction.

Conversion of Mechanical Energy to Electrical Energy: The induced current in the stator windings produces alternating current (AC) electricity. The frequency and voltage of the AC electricity depend on the design and speed of the generator.

Power Output: The AC electricity generated by the generator can be used to power electrical devices or can be converted to direct current (DC) using a rectifier for specific applications.

Overall, an electric generator converts mechanical energy into electrical energy through the principles of electromagnetism and electromagnetic induction.

The parts of an electric generator involved in the process are:

Mechanical Energy Input: This includes a turbine or an engine that provides the mechanical energy to rotate the rotor.

Rotor: The rotor is the rotating part of the generator that contains electromagnets or permanent magnets.

Stator: The stator is the stationary part of the generator where the induction of electric current takes place. It consists of coils of wire.

Electromagnetic Induction: This is the principle that allows the changing magnetic field of the rotor to induce an electric current in the stator.

Stator Windings: These are the coils of wire in the stator that generate the induced current.

Power Output: The generated electricity can be used to power electrical devices or converted to direct current (DC) using a rectifier.

Overall, the main parts involved in the process of an electric generator are the mechanical energy input, rotor, stator, electromagnetic induction, stator windings, and power output.

OTHER KEY CONCEPTS

Electricity is related to magnetism.

Magnetic fields can produce electrical current in conductors.

Electricity can produce a magnetic field and cause iron and steel objects to act like magnets.

Electromagnets are temporary magnets that lose their magnetism when the electric current is removed.

Both a motor and a generator have magnets (or electromagnets) and a coil of wire that creates another magnetic field.

A generator is a device that converts mechanical energy into electrical energy.

Most of the electrical energy we use comes from generators.

Electric motors convert electrical energy into mechanical energy that is used to do work.

Examples of motors include those in many household appliances, such as blenders and washing machines.

Difference Between Motor and Generator

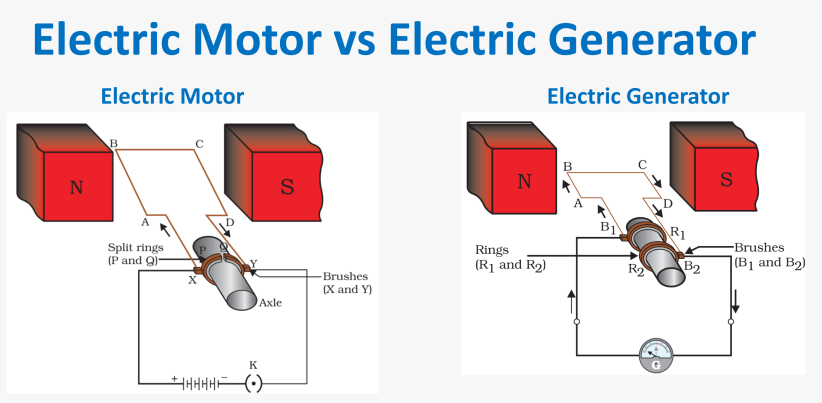

Sl. No. | Differentiating Property | Motor | Generator |

1 | Definition | An electric motor is a machine that converts electrical energy to mechanical energy. | An electric generator is a machine that converts mechanical energy to electrical energy.` |

2 | Rule | Electric motor follows Fleming’s left-hand rule. | Electric generator follows Fleming’s right-hand rule. |

3 | Principle | The working principle of a motor is based on the current-carrying conductor that experiences a force when it is kept in the magnetic field. | The working principle of the generator is based on electromagnetic induction. |

4 | Driving force for shaft | The shaft of an electric motor is driven by a magnetic force which is developed between the armature and field. | The shaft of an electric generator is connected to the rotor which is driven by a mechanical force. |

5 | Current Usage | In a motor, current is supplied to the armature winding. | In a generator, current is produced in the armature winding. |

6 | Example | Ceiling fans, cars, etc. are all examples of motors. | In power stations, generators are used to generate electricity. |