W3_lecture1 CE and sustainability(1)

Module Overview

Course Code: ENVE4610

Title: Engineering the Circular Economy

Module: 2 - Circular Economy

Introduction to Circular Economy

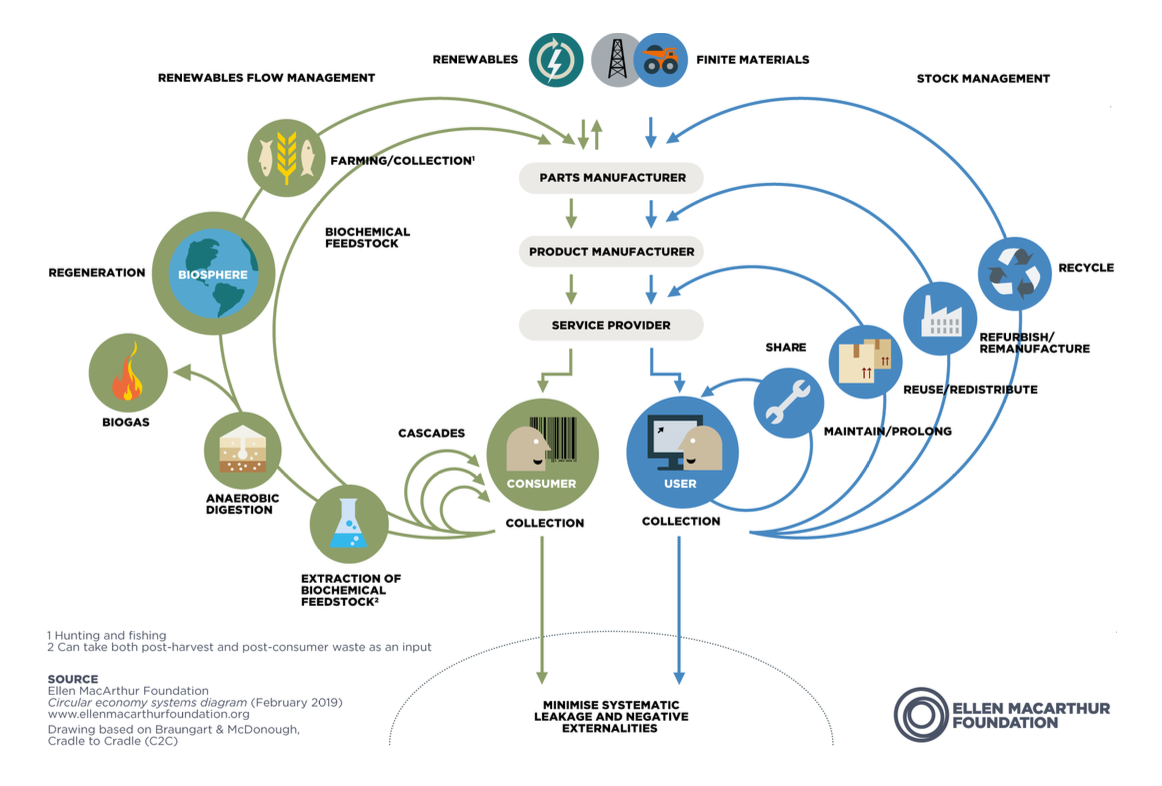

Definition: A circular economy emphasizes designing out waste and pollution, maintaining product and material usage, and regenerating natural systems.

It operates at three levels:

Micro (individual products and consumers)

Meso (eco-industrial parks)

Macro (city to global levels)

Objectives: Create environmental quality, economic prosperity, and social equity for present and future generations through responsible practices and innovative business models.

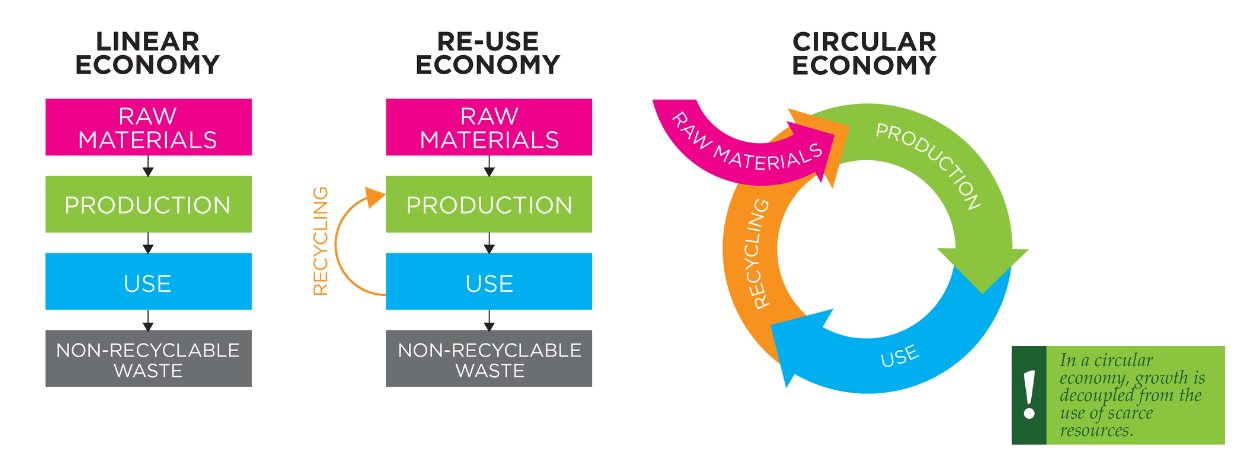

Linear vs Circular Economy

Linear Economy

Process: Take -> Make -> Use -> Waste

Involves production of non-recyclable waste.

Circular Economy

Process: Take -> Make -> Use -> Reuse/Recycle

Emphasizes decoupling economic growth from resource consumption.

Key Shift: Growth without use of scarce resources to minimize waste.

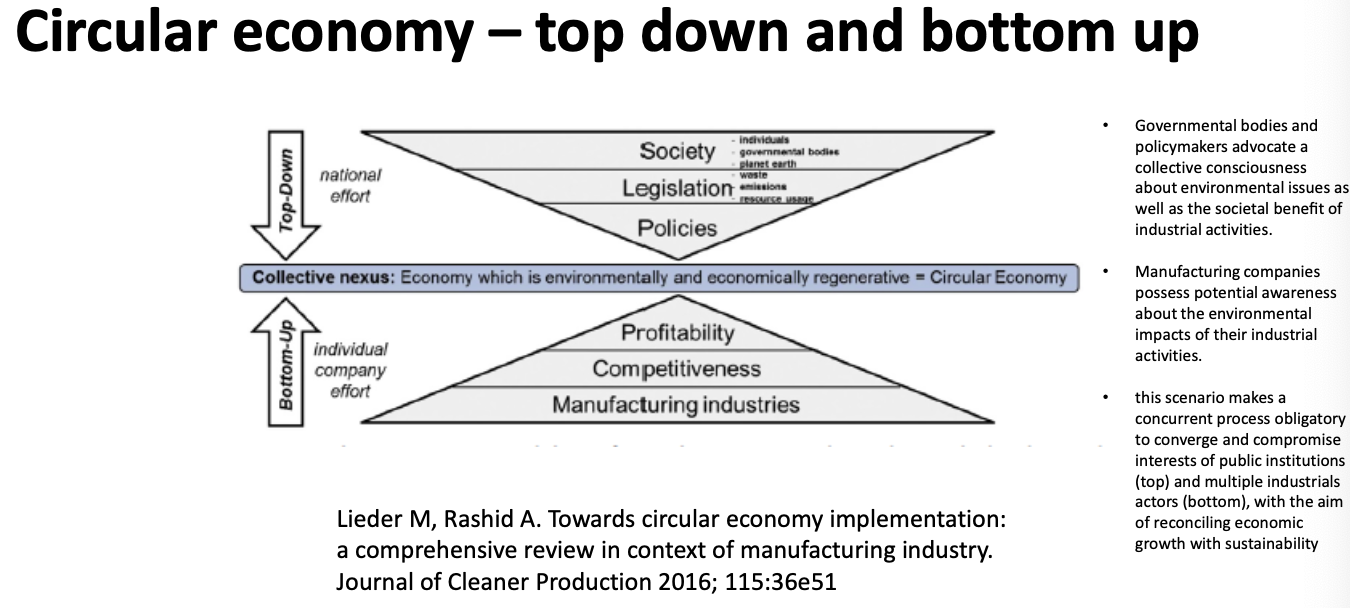

Circular Economy Principles

Closed Resource Loops: Aim for complete closure to eliminate virgin resource reliance.

Resource Flow Optimization: Ensure inputs and outputs balance; requires management of resource flow.

Multi-Level Concept: Involvement of micro (businesses), meso (industrial clusters), and macro (policy) levels.

Thermodynamics and Human Error: Perfect circularity is unrealistic; requires diverse approaches for sustainable resource management.

Benefits of Circular Economy

Economic: Increased revenues, decreased production costs, savings on material costs, employment growth in recycling/remanufacturing sectors.

Environmental: Improved land productivity/health, lower CO2 emissions, pollution reduction.

Circular Economy vs Sustainability

Sustainability: Meeting present needs without compromising future generations. It encompasses economic, environmental, and social pillars (people, planet, profits).

Circular Economy: Focuses on waste elimination and resource regeneration, aligning with sustainability goals.

Digitalization in Circular Economy

Importance: Real-time tracking of products improves end-of-life management, enables predictive maintenance, and enhances resource recovery.

Technologies: RFID for tracking, IoT for monitoring, data integration tools for managing product life cycles.

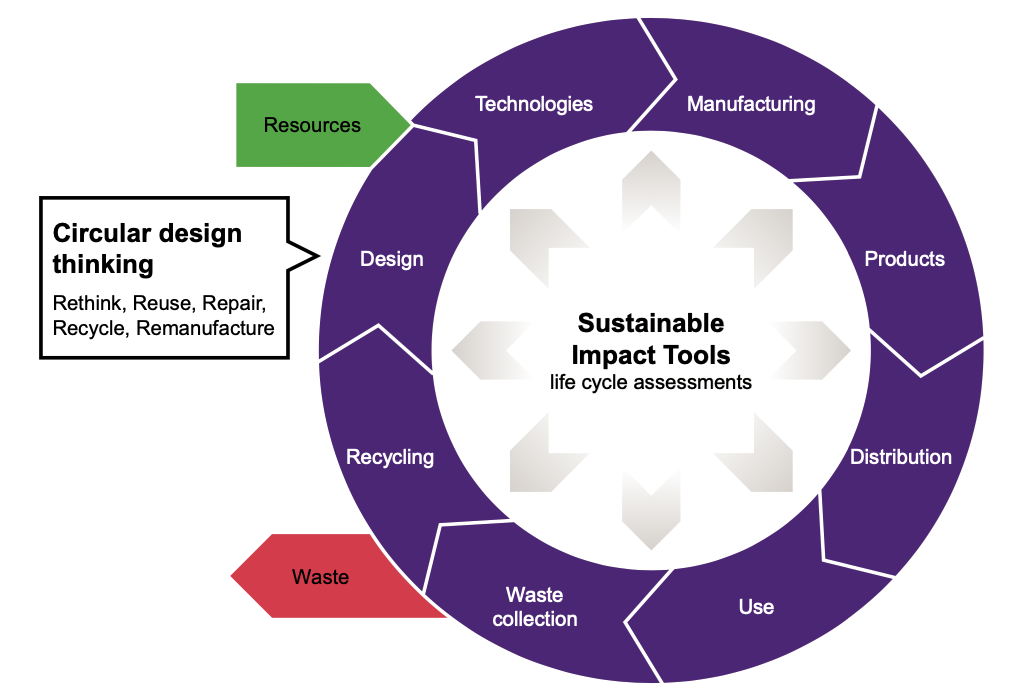

Circular Design Strategies

Design for Reuse: Create durable products that can be used multiple times.

Design for Repair: Facilitate easy repairs to extend product lifespan.

Design for Remanufacturing: Rebuild used products to restore them to working condition.

Design for Recycling: Ensure products can be efficiently broken down and materials recycled.

Digitising the Circular Economy

Importance

Real-time tracking of products improves end-of-life management.

Enables predictive maintenance to maximize product lifespan.

Enhances resource recovery through data-driven insights.

Technologies

RFID (Radio-Frequency Identification): For tracking assets throughout their lifecycle.

IoT (Internet of Things): For monitoring product conditions and usage patterns.

Data Integration Tools: For managing product life cycles efficiently, ensuring transparency and accountability.

Future Trends and Challenges

Adaption to stricter policies, climate changes, and growing customer demands for sustainability.

Businesses shifting from selling products to providing services (e.g., rentals, subscriptions).

Key Takeaways

The course offers an in-depth understanding of circular economy principles, sustainability interconnections, and design strategies.

A holistic approach incorporates engineering, sustainability assessments, logistics, and social aspects in product/process design.

Knowt

Knowt