D&T_Unit2_Revision

Unit 2

Resource Managment and Sustainable Production

2.1 -- Resources and Reservers

As non-renewable resources run out, designers need to develop innovative solutions to meet basic human needs for energy, food and raw materials. The development of renewable and sustainable resources is one of the major challenges of the 21st century for designers.

Much of the development of new resources is the product of creating sustainable solutions to existing problems.

The legacy of the industrial revolution is now being felt as we face resource depletion. The challenge for designers is to continue to develop products that meet the needs of humans, while conserving the environment for future generations.

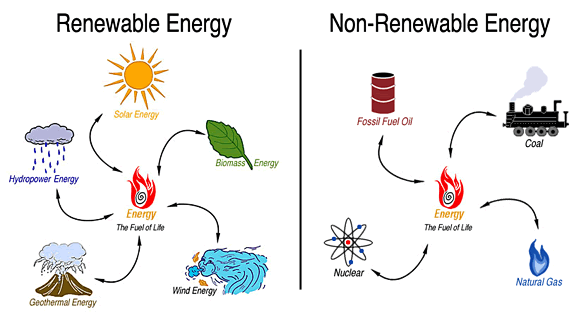

Renewable and Non-Renewable Resources

Renewable resource

Term: A natural resource that can replenish with the passage of time or does not abate at all

- These include, solar, wind, hydro, wave, tidal, thermal and bio fuels

- A natural resource qualifies as a renewable resource if it is replenished by natural processes at a rate almost the same as its rate of consumption by humans or other users.

Renewability

Term: This term refers to a resource that is inexhaustible therefore can be replenished quick enough.

- Hardwood trees (such as many rainforest species) take a fair bit of time to mature to a point where is is useable as a resource, therefore, it is considered non-renewable. On the other hand, softwoods (such as pines or conifers) mature more quickly and are considered a renewable resource.

Renewable vs Non renewable

Non-renewable resources

Term: A natural resource that does not replenish at a sustainable rate; a source that will run out if the rate of extraction is maintained.

- These include fossil fuels such as natural gas, oil, coal, gasohol and nuclear energy

- These resources are very useful sources of energy. This energy is needed to manufacture products and provide power to businesses, factories and homes.

- The bad aspect about this is that these resources are running out and the human dependency on them is very high.

Reserves

Term: A natural resource that has been identified in terms of quantity and quality.

- A proven reserve are those resources that can be economically and technically extracted.

- Reserves exist but it might not be viable at this moment such as gold in seawater

Economic and Political Importance

The extraction of oil has been at the centre of may issues removing around resource security and international treaties. Students need to understand the issues/impact surrounding resources security for Nations/Governments and international treaties.

- Governments need to balance the economic benefits and political impact (including social aspects) of resource extraction.

- The Invasion of Kuwait in 1990 is one such example. Iraq was accusing the Kuwait government of ‘slant drilling‘ from the border into Iraqi reserves thus stealing Iraqi oil. It is also thought to be that Iraq invaded in order to procure Kuwaiti oil that were considered to be 20% of the global reserves. A third reason was that Kuwait was over producing oil this dropping the price of global oil which affect the Iraqi economy.

- Often, multinational companies licensed to extract resources have limited consideration for the local population.

- Oil companies are often brought into country to explore possible new fields and then develop them. The oil companies pay the government a set amount which can develop wealth. This can produce local employment and other opportunities.

- Rare earth minerals/elements which are highly desired/needed and valuable came with a set of issues. For the countries that have them can receive a financial windfall, local communities gain skilled employment, however, the environmental impact for local communities is damaging. An article from the TheGuardian.

- The economic and political importance of material and land resources and reserves considering:

- set-up cost – typically are high and perhaps national/local governments cannot afford to set-up the infrastructure and the extraction site so outside multi-nationals could be invited.

- efficiency of conversion –

- sustainable and constant supply –

- social impact – can bring jobs (skilled and unskilled) and wealth, employment could be permanent or temporary (short term excavation/extraction),

- environmental impact – as mentioned above

- decommissioning – economically quite expensive especially with nuclear reactors

2.2 WASTE MITIGATION STRATEGIES

The abundance of resources and raw materials in the industrial age led to the development of a throwaway society, and as resources run out, the many facets of sustainability become a more important focus for designers. The result of the throwaway society is large amounts of materials found in landfill, which can be considered as a new source to mine resources from.

The exploration of possible solutions to eliminate waste in our society has given rise to ideas developed as part of the circular economy. By redesigning products and processes, the waste from one product can become the raw material of another.

Strategies to Mitigate Waste

Re-use

Term: This is reusing a product in the same context or in a different context.

- Reusing is utilising an object more than one time.

- This takes into account of conventional reuse where the object is used again for similar purpose, and new-life reuse where it is used for an innovative purpose.

- An example of reusing is using disposable plastic or glass bottles to drink water from over again.

- Reusing car tyres

Recycle

Term: Recycling refers to using the materials from obsolete products to create other products.

- Recycling consists of processing used materials into novel products in order to avert squandering potentially functional materials.

- It decreases the consumption of unsullied raw resources, trims down energy usage, lowering air and water pollution by dropping the need for “usual” waste discarding, and lastly lowering greenhouse gas emissions.

- An example of recycling is recycled paper.

Repair

Term: Is the reconstruction or renewal of any part of an existing structure or device.

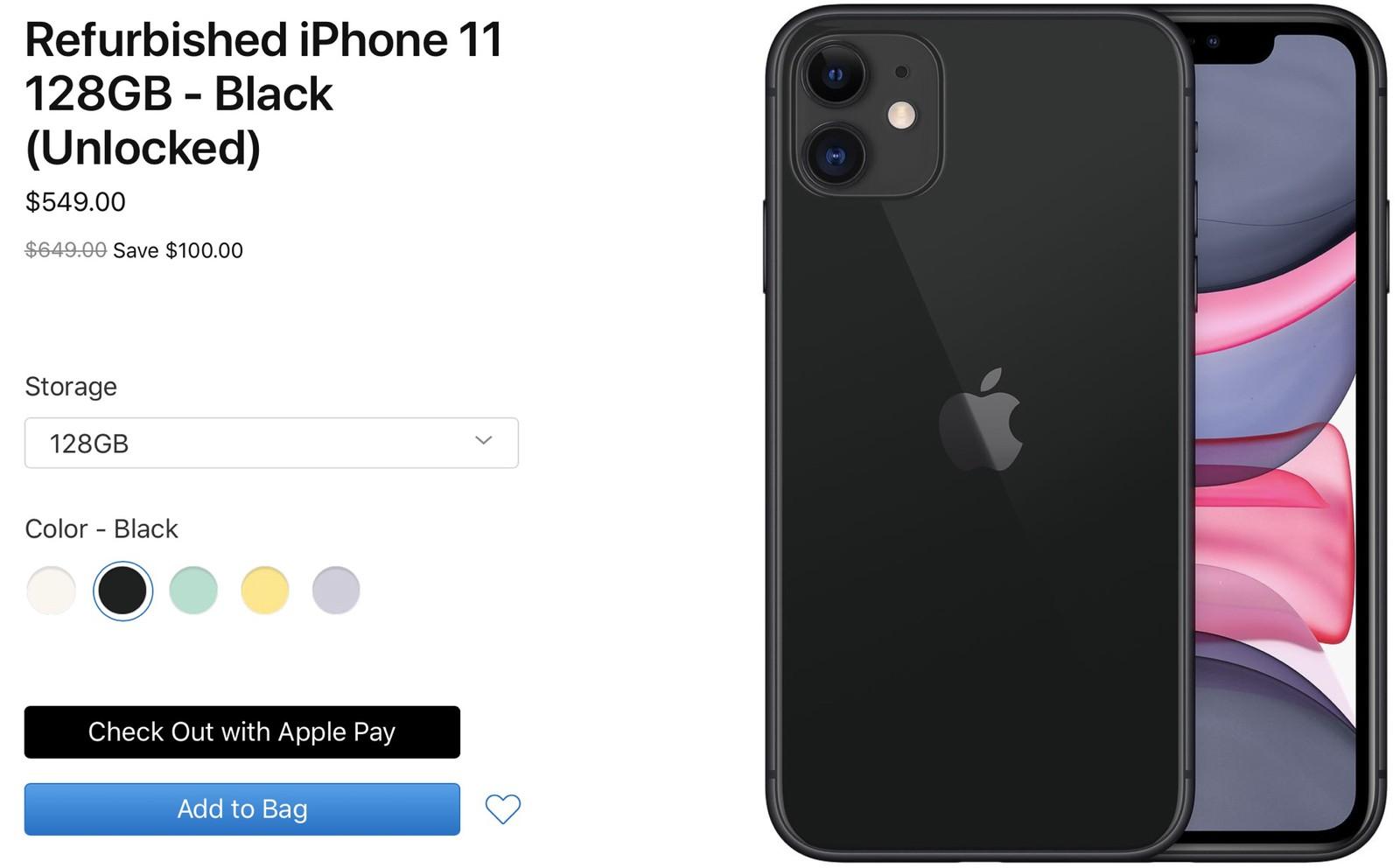

Recondition

Term: Reconditioning is rebuilding a product so that it is in an “as new” condition, by repairing it, cleaning it, or replacing parts.

- Contexts include car engines, tyres or refurbished electronics.

Re-engineer

Term: A re-engineered product has been significantly redesigned, with improved engineering, from its original form.

- In may: use raw materials that were meant another product or manufacturing process, use environmentally friendly materials, recycle some of the original components, improve performance.

- The Dyson Ball Vacuum cleaner has been re-engineered. The vacuum still functions in collecting dust but the method of doing it is different. They redesigned the suction system.

Re-engineered Dyson Vacuum Cleaner (follow Link)

Pollution & Waste

From Wikipedia “Pollution is the introduction of contaminants into the natural environment that cause adverse change.[1] Pollution can take the form of chemical substances or energy, such as noise, heat or light. Pollutants, the components of pollution, can be either foreign substances/energies or naturally occurring contaminants.

Landfill in Poland

Landfill in Poland

From Wikipedia, Wastes are unwanted or unusable materials. Waste is any substance which is discarded after primary use, or it is worthless, defective and of no use.

Something to ponder? – This is subjective as one persons idea of waste may whereas another person may find it useful!

- Smokey Mountain in the Philippines

- Zabbaleen of Mokkattam in Cairo

Methodologies for Waste Reduction and Designing out Waste

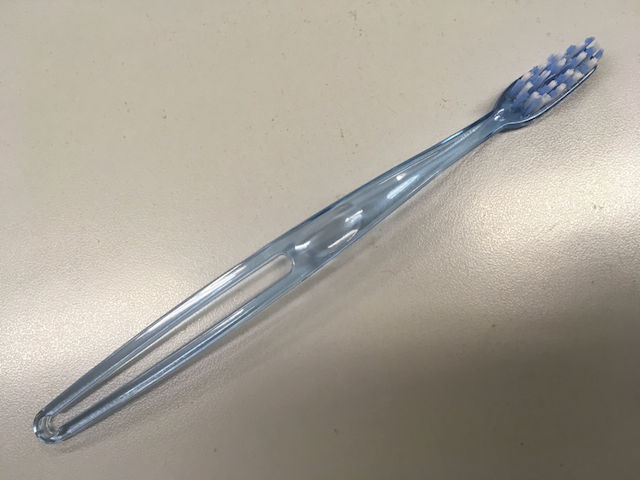

Dematerialization

Term: The reduction of total material and energy throughput of any product and service.

Dematerialization of a Toothbrush

Dematerialization of a Toothbrush

- Dematerialization improves product efficiency by saving, reusing or recycling materials, components and products.

- It impacts on every stage of the product life cycle: in material extraction; eco-design; cleaner production; environmentally conscious consumption patterns; recycling of waste.

- It may mean smaller, lighter products and packaging; the replacement of physical products by virtual products (email instead of paper, web pages instead of brochures); home working, and so on.

- Reduction of total material and energy throughput of a product or service, and the limitation of its environmental impact through: reduction of raw materials at the production stage; energy and material inputs at the user stage; waste at the disposal stage

- There are potential results of successful dematerialization ..

Product Recovery Strategies at End of Life/Disposal

Term: The processes of separating the component parts of a product to recover the parts and materials.

- Use and recovery of standard parts at the end of product life.

- Recovery of raw materials.

- Take back legislation.

- Trade in.

- Recycling bins/locations.

- Employ a circular economy.

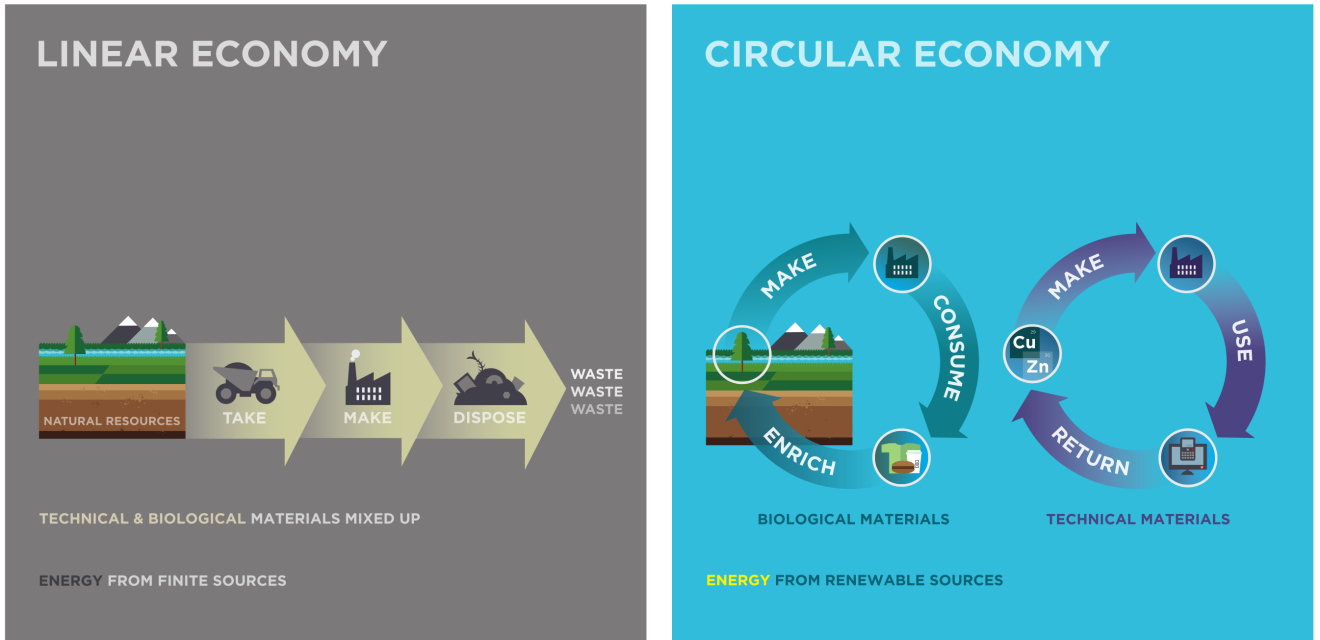

Circular Economy

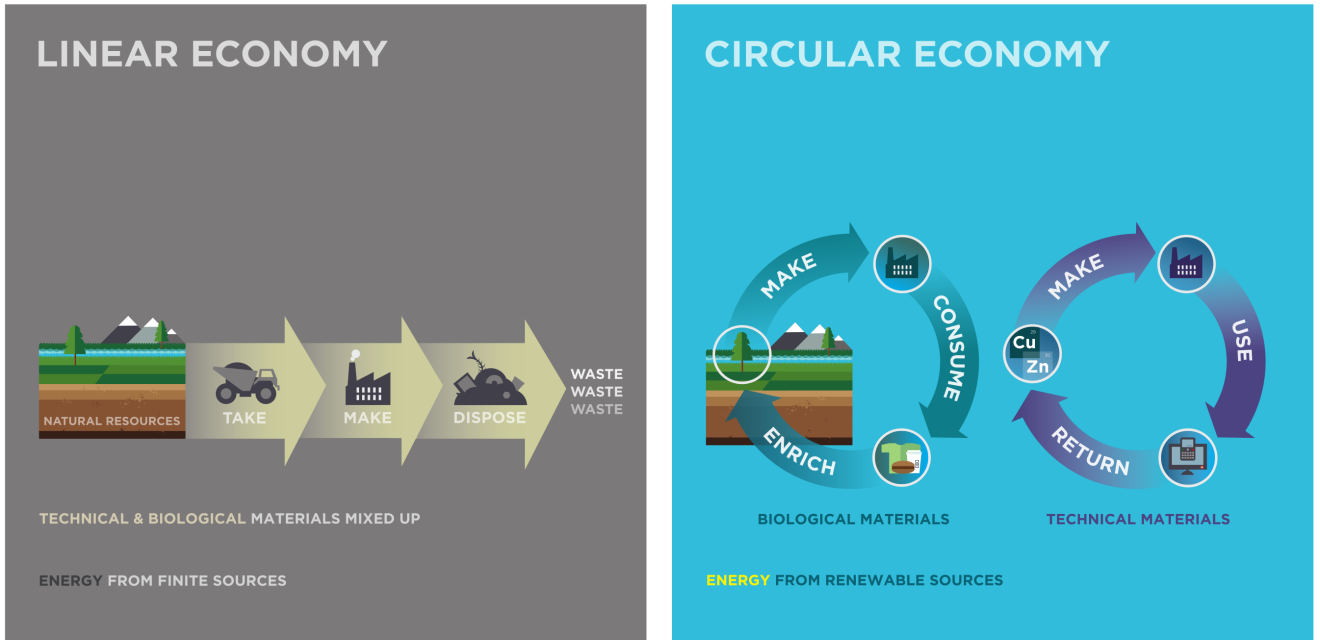

Term: An economy model in which resources remain in use for as long as possible, from which maximum value is extracted while in use, and the products and materials are recovered and regenerated at the end of the product life cycle.

- In an economic model that is a closed loop system where the materials/resources are in constant use. At the end of the product life cycle the material waste (or obsolete product material) is recycled/recovered.

- The material waste is a resource in the system and is regenerated at he end of the product life cycle.

- A circular economy requires designers to consider the subsequent use of materials, components and the embedded/embodied energy in a product.

- This can only be achieved by innovative design and consideration of further cycles of development.

- Designers must ask themselves the question, “How can this product be made to be made again?”

- There are three central strands to this concept:

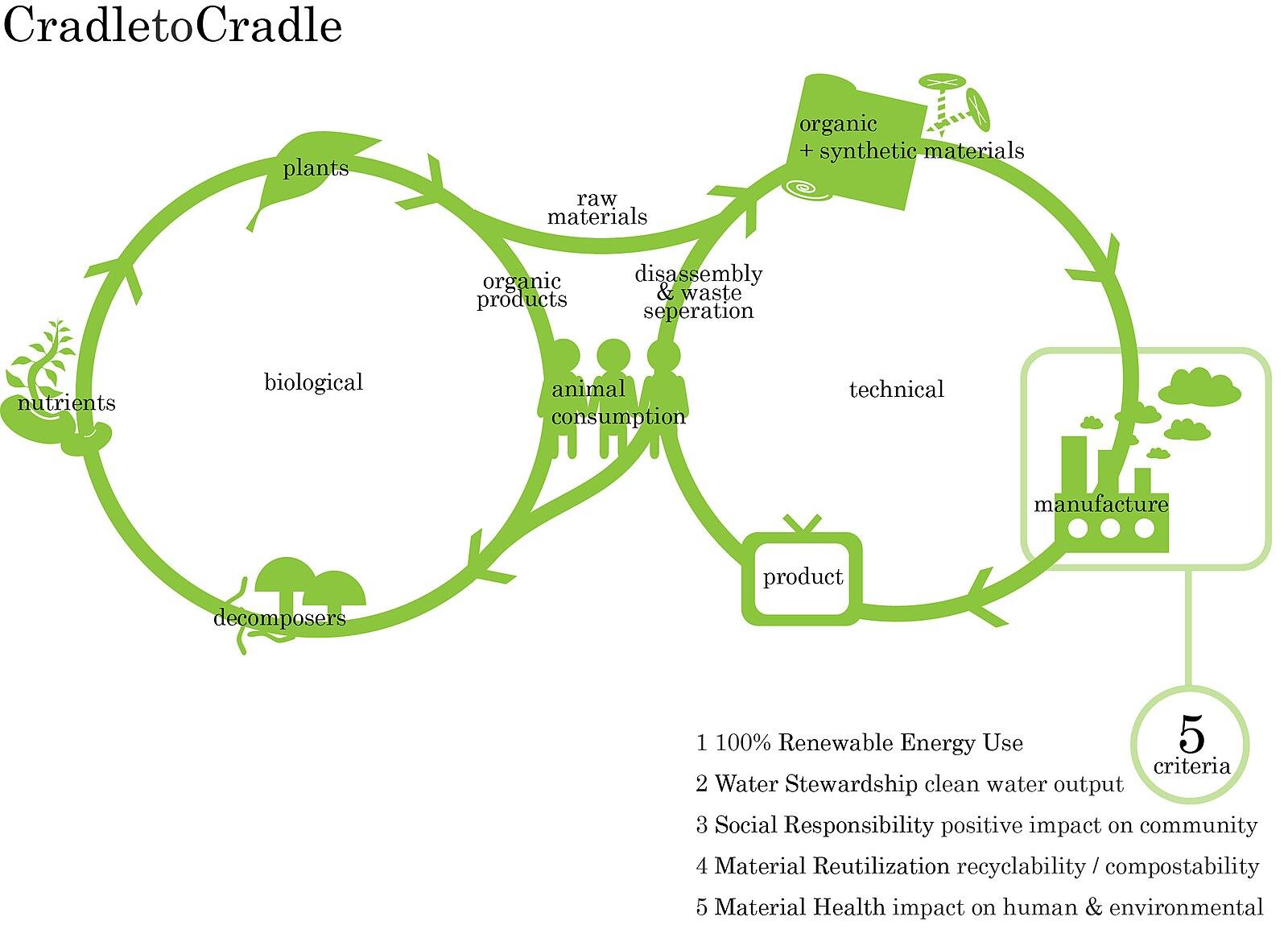

- cradle-to-cradle (Topic 2.6) design thinking which looks at the whole design and manufacturing process.

- design for disassembly (Topic 4.5) which allows for recovery of materials and components.

- design inspired by nature that favours diversity and in which there is no waste (biomimicry).

- Innovative design techniques might include:

- the use of smart (shape) memory screws,

- dissolvable circuit boards and adhesives (glue),

- the use of clips rather than adhesives or screws,

- biological materials (such as bioplastics) that can be safely returned to the biosphere with no toxic dyes or other materials.

- Equally important are the systems in which the product moves: How will the materials or components be recovered and made use of again.

- The designer and manufacturer need to consider this when developing products.

- One way forward is to develop different business models where users buy performance through leasing rather than purchasing. This offers interesting job opportunities in creating reverse supply chains as well as engaging design challenges and opportunities.

- Splosh – A company has set where a customer purchases a one-off starter kit and then fill the bottle with a sachet of cleaning liquid add warm water and they already to go.

- The adding water reduces packing (reduction of materials) and weight (important for transportation – reduction is fuel)

- Saves on materials, energy and waste.

- If the bottle is reused 20 times it means 95% less packaging waste

The linear and circular models of the economy from Ellen MacArthur Foundation

- The above models show the traditional linear, where material is extracted, manufactured and diseased in landfill. The circular model – one of them the bio-waste is returned to enrich the earth. The left model the technical waste is recycled and rescued in the continued production.

- Ellen MacArthur Foundation of Circular economy includes overview, diagrams and case studies.

Final Word: Designing out waste and designing for closed-loop recycling will be more important as resources become scarcer and waste becomes more expensive. Therefore, developing products for product recovery and dematerialization will become an essential element of innovation.

- A circular economy requires designers to consider the subsequent use of materials, components and the embedded/embodied energy in a product.

- This can only be achieved by innovative design and consideration of further cycles of development.

- Designers must ask themselves the question, “How can this product be made to be made again?”

- There are three central strands to this concept:

- cradle-to-cradle (Topic 2.6) design thinking which looks at the whole design and manufacturing process.

- design for disassembly (Topic 4.5) which allows for recovery of materials and components.

- design inspired by nature that favours diversity and in which there is no waste (biomimicry).

- Innovative design techniques might include:

- the use of smart (shape) memory screws,

- dissolvable circuit boards and adhesives (glue),

- the use of clips rather than adhesives or screws,

- biological materials (such as bioplastics) that can be safely returned to the biosphere with no toxic dyes or other materials.

- Equally important are the systems in which the product moves: How will the materials or components be recovered and made use of again.

- The designer and manufacturer need to consider this when developing products.

- One way forward is to develop different business models where users buy performance through leasing rather than purchasing. This offers interesting job opportunities in creating reverse supply chains as well as engaging design challenges and opportunities.

- Splosh – A company has set where a customer purchases a one-off starter kit and then fill the bottle with a sachet of cleaning liquid add warm water and they already to go.

- The adding water reduces packing (reduction of materials) and weight (important for transportation – reduction is fuel)

- Saves on materials, energy and waste.

- If the bottle is reused 20 times it means 95% less packaging waste

The linear and circular models of the economy from Ellen MacArthur Foundation

The linear and circular models of the economy from Ellen MacArthur Foundation

- The above models show the traditional linear, where material is extracted, manufactured and diseased in landfill. The circular model – one of them the bio-waste is returned to enrich the earth. The left model the technical waste is recycled and rescued in the continued production.

- Ellen MacArthur Foundation of Circular economy includes overview, diagrams and case studies.

Final Word: Designing out waste and designing for closed-loop recycling will be more important as resources become scarcer and waste becomes more expensive. Therefore, developing products for product recovery and dematerialization will become an essential element of innovation.

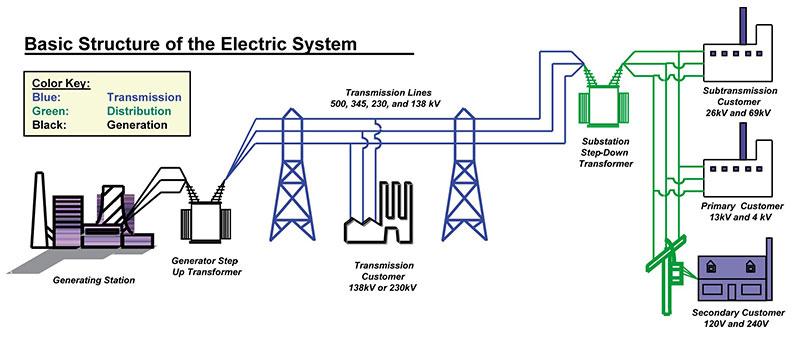

Distributing Energy: National and International Grid Systems

Term: National and international grid systems – An electrical supply distribution network that can be national or international. International grids allow electricity generated in one country to be used in another.

Term: Energy Distribution -The method with which energy is transported from a source to where it is used.

- Energy is distributed over a national and international grid systems

- Egypt’s Aswan Dam produces enough electricity that Egypt sells it to The Sudan. On the USA and Mexico border there are three locations where power is sent across the border.

- Power nationally distributed is sent for domestic, commercial and industrial use including electric vehicles.

- This is a highly centralised grid system.

|

|

|---|---|

|

|

Local Combined Heat and Power (CHP)

Term: A system that simultaneously generates heat and electricity from either the combustion of fuel, or a solar heat collector.

- t is an efficient and clean approach to generating electric power and thermal energy from a single fuel source.

- It can either replace or supplement conventional separate heat and power.

- Instead of purchasing electricity from the local utility company and burning fuel (oil, gas etc) in an on-site furnace or boiler to produce thermal energy.

- This can be taken care of by an industrial or commercial facility can use CHP to provide both energy services in one energy-efficient step. from the EPA website.

- Reduces the negative impact to the environment

- Saves the consumer money

- Also known as co-generation

![]() CHP and efficiency

CHP and efficiency

Systems for Individual Energy Generation

Term: Individual energy generation is the ability of an individual to use devices to create small amounts of energy to run low-energy products.

- is the small-scale generation of heat and electric power by homes (also small businesses and small communities) to meet their own needs.

- It is an alternative or can supplement traditional centralized grid-connected power.

- Lower negative impact on the environment

- Lower costs for the consumer

- High initial capital cost

- Can sell excess electrical power back to the National Grid

- BBC article on Generating, storing and selling in your home.

- Also known as micro-generation

House with self generation

House with self generation

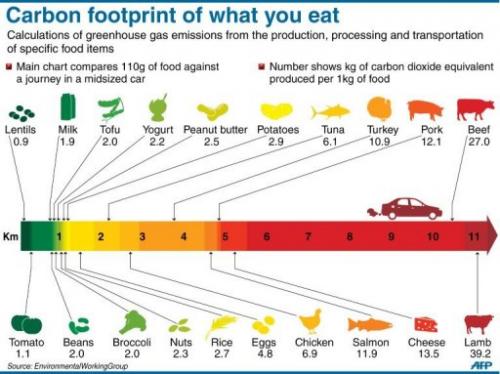

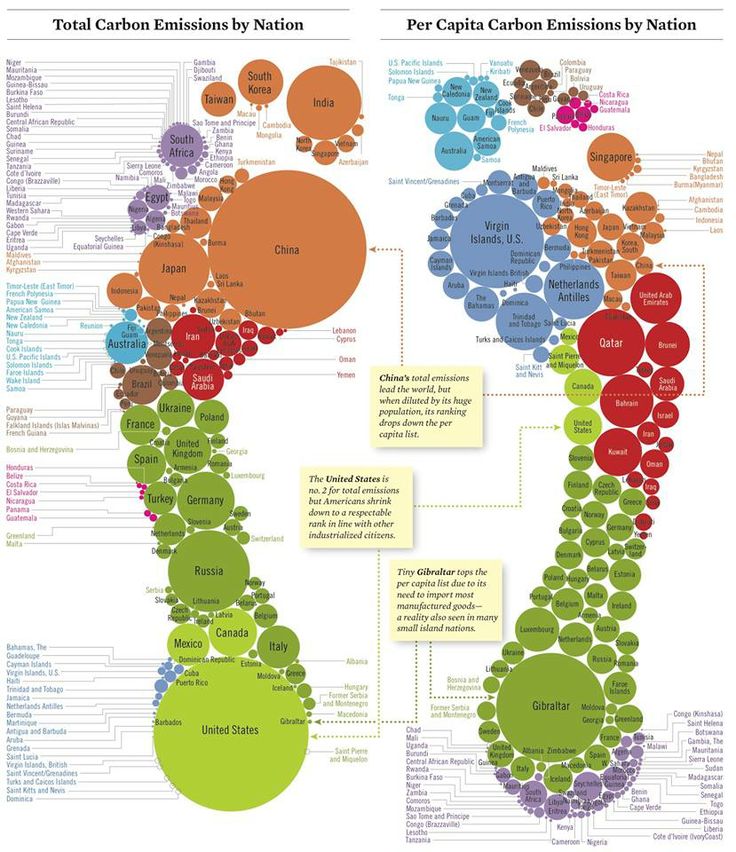

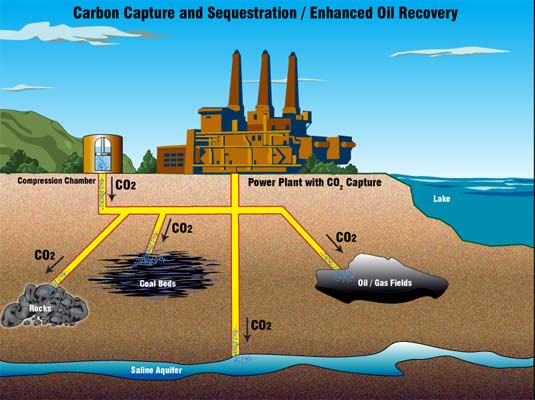

Quantification and Mitigation of Carbon Emissions

Term: Quantification of carbon emissions – Defining numerically the carbon emissions generated by a particular product

|

|

|---|

Quantification

- record carbon emissions

- discover how much is being produced

- discover who/ where it is produced

- track your carbon footprint

Mitigation

- Humans intervention in the reduction of carbon emissions

- These contribute to global warming

- Resulting in melting polar caps, rising seas, desertification,

- provide ‘Sinks’ that can reabsorb carbon emissions

- A ‘Sink’ are forests, vegetation or soils.

- UN Article on Mitigation

Energy Storage – Batteries, Capacitors and Capacities

Term: Energy Storage –The method with which energy is stored for later use.

- Battery is a device consisting of two or more electrochemical cells that convert stored chemical energy into electrical energy (Wikipedia)

- Capacitor is an electronic component that temporally stores electrical energy.

- Capacity is the amount of electric charge it can deliver (measured in amp-hours)

- Batteries have a huge impact on the portability of electronic products –

- Through the development of new technologies, batteries have become more efficient and smaller.

|

|

|---|

Types of Batteries

See the table below with regards to the relative cost, efficiency, environmental impact and reliability of different types of batteries.

Battery Type | Relative Cost | Efficiency | Environmental Impact | Reliability | |

|---|---|---|---|---|---|

| High | Medium | Low | ||

| Medium | High | Low | ||

| High | Medium | High | ||

| Low | Low | High | ||

| High | High | Low |

- The environmental impact can be assessed using an environmental impact assessment matrix and life cycle analysis (LCA).

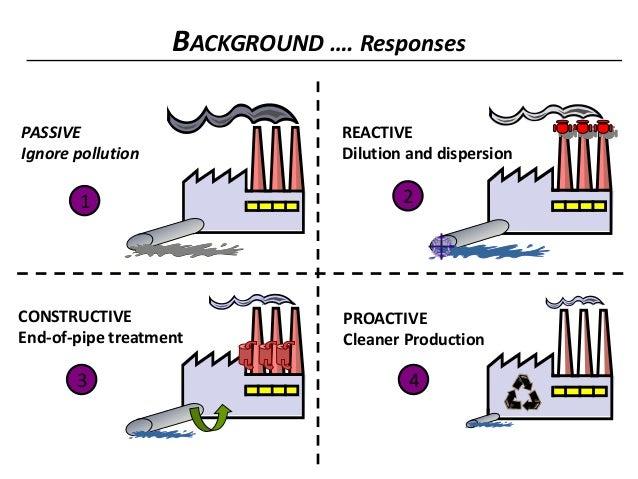

2.4 CLEAN TECHNOLOGY

Clean technology is found in a broad range of industries, including water, energy, manufacturing, advanced materials and transportation. As our Earth’s resources are slowly depleted, demand for energy worldwide should be on every designer’s mind when generating products, systems and services. The convergence of environmental, technological, economic and social factors will produce more energy-efficient technologies that will be less reliant on obsolete, polluting technologies.

The legislation (law) for reducing pollution often focuses on the output and, therefore, end- of-pipe technologies. By implementing ideas from the circular economy, pollution is negated and waste eliminated.

Drivers (push) for Cleaning up Manufacturing:

Manufacturers may react to:

- Legislation is a driving force for industry to clean up manufacturing processes.

- current or forthcoming legislation (laws)

- to conform with government legislation

- to avoid penalties

- Pressure created by the local community and media

- communities have made it known that they don’t want harmful (to humans, ecology and the environment) industries

- pressure groups such as Greenpeace or even a small community town

- this can sometimes force legislation to be developed and enacted

Reasons for cleaning up manufacturing/industry include:

- promoting positive impacts

- ensuring neutral impact or minimizing negative impacts through conserving natural resources

- reducing pollution and use of energy

- reducing waste of energy and resources

International Legislation and Targets

International legislation and targets are developed for reducing pollution and waste:

Term: Legislation – Laws considered collectively to address a certain topic.

- The role and scale of legislation are dependent upon the type of manufacturing and the varied perspectives in different countries.

- Legislation (as mentioned above) provides a motivation (perhaps not willingly) for industry to clean up manufacturing processes.

- Manufacturers react to the legislation by cleaning up there act or ignoring it (this happens in some countries as legislation not be forced).

- Manufacturers dont want to pay to clean up production; this cuts into profits.

- International targets, such as those of the Kyoto Protocol in 1997 (see video below), The Copenhagen Accord in 2009, The Paris Agreement in 2015 are set and agreed upon for reducing green house gases to combat global warming.

- The difficulties of getting nations to agree to the targets which can be for many reasons, such as, nations being at different stages of economic and social development, attitudes to the the environment, or placing more value on economic gain than the environment.

- Legislation is monitored and policed and how it can be promoted for manufacturers.

- How legislation can be monitoring and policing

- The UN on water

- Legislation (as mentioned above) provides a motivation (perhaps not willingly) for industry to clean up manufacturing processes.

- Is it ethical to prevent a developing country from producing high carbon emissions through industrial development when developed countries have been the main generators of carbon emissions through their own industrial revolutions and economic development?

- China is a current example as it has done in 20 odd years what it took USA and Europe about 100 years.

Incremental and Radical solutions

Incremental solutions

Term: Incremental solutions – Products which are improved and developed over time leading to new versions and generations.

- Often, manufacturing processes are improved in terms of efficiency and amount of embodied energy over time.

- This incremental development of a manufacturing process can require major refits and the addition of new elements to a manufacturing process.

- Which allows a company to plan strategically how it will make he changes – this allows for better budget control but requires long term planning.

- the impact is not as drastic as radical solutions.

Advantages | Disadvantages |

|---|---|

Use of existing trusted technologies. | Take too long. |

No/limited down time in production (continued profits) | Small changes may not meet the overall legislation requirements. |

Less uncertainty of success due the trusted, known technology. | Need to make small changes often. |

Can quickly respond to legislation (forthcoming or changing). | Saturated (crowded) marketplace/ competition. |

Radical solutions

Term: Radical solutions – Where a completely new product is devised by going back to the roots of a problem and thinking about a solution in a different way.

- Radical solutions can make a great and sudden impact;

- They can require the replacement of a whole system.

- This can be costly and time consuming where a company maybe in down time

Advantages | Disadvantages |

|---|---|

Exploration of new technologies. | Costly (both if technology outfitting and loss of profits during down time). |

High potential for market growth. | Costly R&D, training and capital (equipment). |

Creation of new industries. | High uncertainty of success. |

Fewer competitors. | Possibility of high market resistance. |

Patening new solutions – financial and repetitional benefits. | Development unpredictable incorporating specific starts and stops. |

Enhance reputation and innovative and radical. |

|

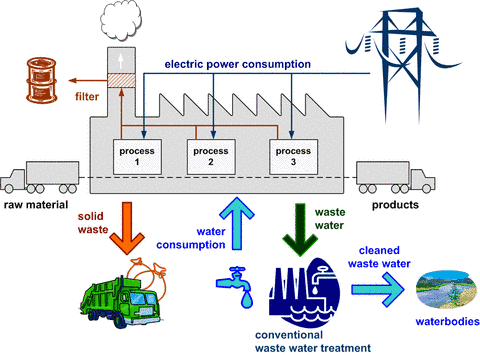

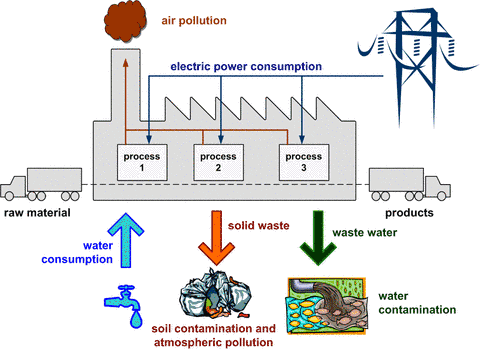

End-of-Pipe Technologies

Term: Technology that is used to reduce pollutants and waste at the end of a process.

- Technology that is used to reduce pollutants and waste at the end of the industries production processes.

- Industries include, water, energy, manufacturing, advanced materials and transportation.

- Example of this are filters installed on the end of industrial smoke stacks.

|

|

|---|---|

End-Of-Pipe | End-Of-Pipe vs Clean Production |

|

|

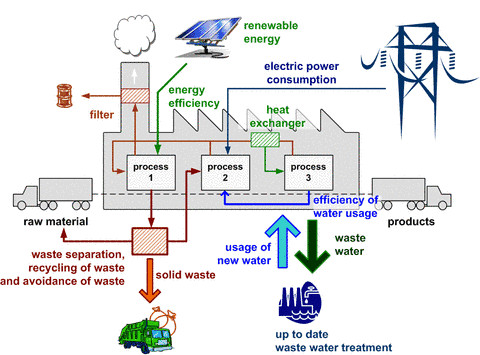

System Level Solutions

Term: Solutions that are implemented to deal with the whole system, rather than just components.

- Is concerned with the prevention of pollutants as a whole – i.e. production system wide

- Often radical implementation

|

|

|---|

Articles of interest

- Clean Production vs End of Pipe

- Clean technology Website from where the images came from

- Clean technology and profits

Clean Technology

Term: Products, services or processes that reduce waste and require the minimum amount of non-renewable resources.

“Clean technology includes recycling, renewable energy (wind power, solar power, biomass, hydropower, biofuels, etc.), information technology, green transportation, electric motors, green chemistry, lighting, greywater, and many other appliances that are now more energy efficient. It is a means to create electricity and fuels, with a smaller environmental footprint and minimise pollution. To make green buildings, transport and infrastructure both more energy efficient and environmentally benign” (wikipedia accessed Jan 19 2016).

|

|

|---|

Examples of Clean Tech

2.5 GREEN DESIGN

The starting point for many green products is to improve an existing product by redesigning aspects of it to address environmental objectives. The iterative development of these products can be incremental or radical depending on how effectively new technologies can address the environmental objectives. When newer technologies are developed, the product can re-enter the development phase for further improvement.

The purpose of green design is to ensure a sustainable future for all.

Green Design – Cradle to the Grave

Green Design – Cradle to the Grave

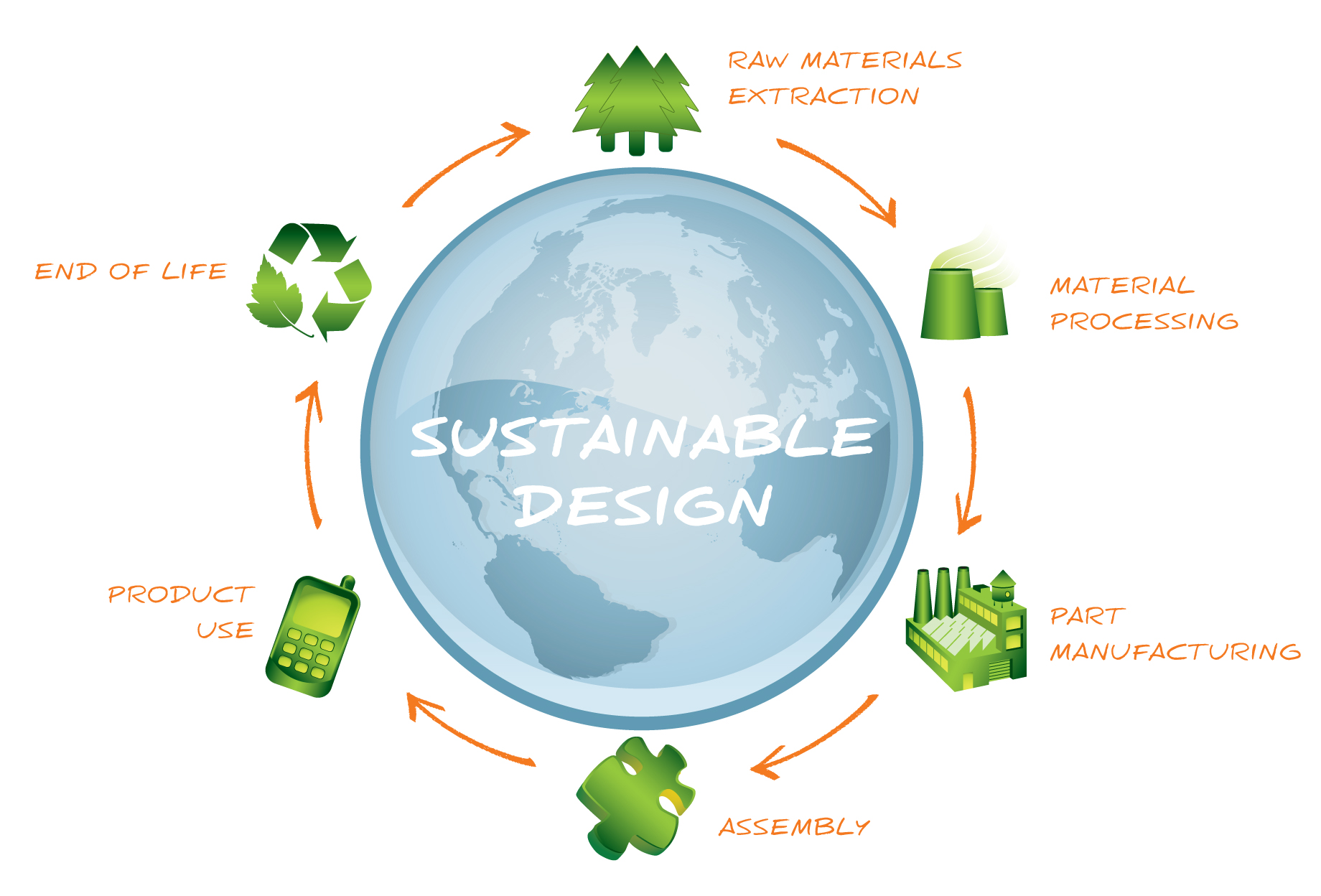

Term: Green design is the designing of products to have a reduced environmental impact throughout its life.

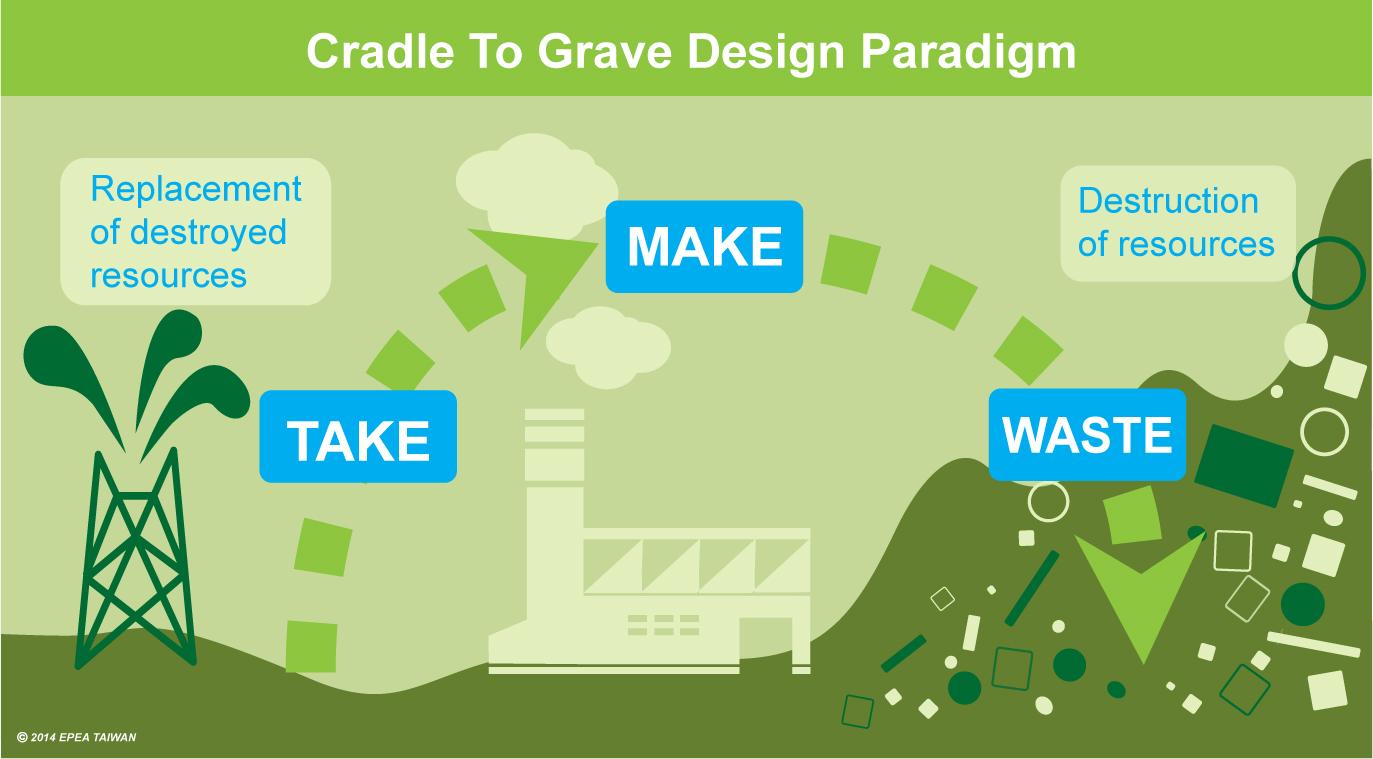

Sustainable products provide social and economic benefits while protecting public health, welfare and the environment throughout their life cycle—from the extraction of raw materials to final disposal (cradle to the grave).

Design objectives for green products

Design objectives for green products fall into three categories, materials, energy and pollution/waste.

Materials

- Ensuring that the packaging and instructions encourage efficient and environmentally friendly use (this can fall under pollution category as well) materials.

- Minimizing the number of different materials used in a product.

- Labelling of materials so they can be identified for recycling.

- Increasing efficiency in the use of materials and resources.

Energy

- Increasing efficiency in the use of energy.

Pollution and waste

- Ensuring that the planned life of the product is most appropriate in environmental terms and that the product functions efficiently for its full life.

- Analysing and minimizing potential safety hazards (not sure where this goes).

- Reducing to a minimum any long-term harm caused by use of the product.

- Reducing or negating environmental damage or pollution from the materials selected.

- Reducing or negating noise or smell pollution.

- Consider the effects of the disposal of the end of life of the product.

Drivers for green design (consumer pressure and legislation)

Drivers for green design include consumer pressure and legislation, among others.

Consumer pressure

Term: Collections of individuals who hold a similar viewpoint on a particular topic, for example the environment, who take action to promote positive change to meet their goals.

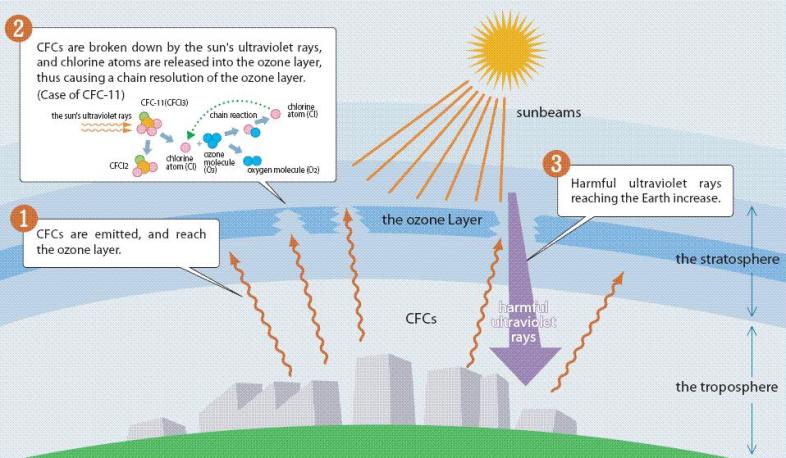

- The public have become aware of environmental issues through media focus on issues such as the destructive effect of chlorofluorocarbons on the ozone layer; acid rain in Northern European forests and the nuclear accident at Chernobyl.

- Increased public awareness has put pressure on corporations and governments through voting and purchasing power.

- The consumer will seek out products that are energy efficient which will be cheaper to run this providing savings for the consumer.

Legislation

Term: Laws considered collectively to address a certain topic.

- Environmental legislation has encouraged the design of greener products that tackle specific environmental issues, for example, eliminating the use of certain materials or energy efficiency.

- Raised awareness of environmental issues is increasing legislation in many countries. This can lead to financial penalties on companies who do not demonstrate environmental responsibility. Many people will not behave responsibly unless forced to do so, therefore, legislation forces the issue.

Examples of legislation:

![]() Plastic Labelling

Plastic Labelling

- One problem in relation to the recycling of plastics is knowing what the plastic actually is. Government legislation requires labelling plastic products with the plastic type can help overcome this issue.

- CFCs, or chlorofluorocarbons, are harmful greenhouse gases that erode the ozone layer, allowing UV rays to be absorbed and trapped into the Earth and causing global warming. CFCs could be found in Styrofoam, air conditioning coolants, and aerosol cans.

- In response (both consumer and government), McDonald chains in several MEDCs (more economically developed countries) were banned from using Styrofoam containers that contained CFCs and were forced to find alternatives to their old packaging. See news article

- Green/High-Performance Building Legislation in the States

Green legislation

![]() Catalytic Converter in Cars

Catalytic Converter in Cars

Term: Are laws and regulations that are based on conservation and sustainability principles, followed by designers and manufacturers when creating green products.

- Green legislation encourages incremental rather than radical changes:

- for example, legislation requiring car manufacturers to install catalytic converters for cars (end-of-pipe technology) which tackles the environmental issue of car emissions.

- Green legislation is effective as it involves incremental changes (refer to Topic 2.4).

The Designer’s Role

The environmental impact of the production, use and disposal of a product can be modified by the designer through careful consideration at the design stage.

In developing the product brief, formulating the product design specification and choosing the material and manufacturing process, the potential environmental impact of the product is assessed with the specific objective of reducing this impact and minimising it over the longer term.

Strategies for green design (incremental and radical)

Most strategies for green design often involve a focus on one or two

![]() Coca Cola Plant Bottle

Coca Cola Plant Bottle

environmental objectives when designing or re-designing products. For example bioplastics in place of traditional plastics like in the PlantBottle from Coca Cola.

There are many other examples of this, such as:

- To choose non-toxic, sustainable-produced or recycled materials which don’t need as much energy to process.

- To manufacture and produce products using less energy.

- To produce products that are long lasting and better functioning so there is less replacement and use of products.

- Design products using the concept of being able to recycle it when its use is done.

Incremental:

Term: Products which are improved and developed over time leading to new versions and generations.

- Are small changes to the design of the product over a period of time.

- This may include changes to:

- Materials

- use recycled or recyclable materials. Composite materials can be difficult, expensive or cant be recycled.

- material optimisation.

- limit the number of materials. A tetra pak has multiple layers of materials which, in the past, made it difficult to recycle.

- Manufacturing techniques – using clean technology such as end-of-pipe.

- Introduce design for disassembly.

- Materials

Radical:

Term: Where a completely new product is devised by going back to the roots of a problem and thinking about a solution in a different way.

- This may include

- making big and courageous whole changes to the design of a product or service.

- complete overhaul of the manufacturing process.

- using radical clean technology systems

Strategies for designing green products

Most strategies for green design involve focusing on one or two environmental objectives when designing or re-designing a product, for example, the use of recyclable materials.

- When evaluating product sustainability consider the following:

- Raw materials used:

- dematerialization.

- low environmental impact materials (eg bio plastics, recycled paper, etc).

- use of recycled or recyclable materials.

- Packaging:

- same as above on ‘raw materials used’.

- Reduce incorporation of toxic materials or VoCs:

- End-of-life disposal issues:

- make it last – reduce obsolescence

- enhance recyclability – design for disassembly

- Energy in production and use (see next point):

- Production methods:

- Clean production.

- energy efficiency.

- Atmospheric pollutants such as VoC’s:

- Raw materials used:

Timescale to implement green design

- A reasonable timescale, generally a short 5 years, is implemented for incremental much longer for radical.

- This allows for manufacturers to plan and develop design objectives

- It is more cost-effective.

Principles Of Environmental Law

The prevention principle

Term: The avoidance or minimization of producing waste in relation to the production, use and disposal of a product.

- Actions should be taken before damage occurs.

- This is usually based on a past catastrophe or prior scientific data/research.

The precautionary principle

Term: The anticipation of potential problems in relation to the environmental impact of the production, use and disposal of a product.

- Actions should be taken so that the risk of damage is avoided.

- There maybe an uncertainty (scientific evidence but perhaps not conclusive) about the risk of environmental harm.

- This allows protective measures to be taken without having to wait until the damage materialises.

- Fir example, we know that air pollution can cause respiratory illness but how much air pollution is acceptable.

2.6 ECO-DESIGN

Consideration of the environmental impact of any product, service or system during its life cycle should be instigated at the earliest stage of design and continue through to disposal. Designers should have a firm understanding of their responsibility to reduce the ecological impact on the planet. Eco-design concepts currently have a great influence on many aspects of design.

The smart phone is an innovative example of converging technologies that combines multiple technologies into one space-saving device. The resultant reduction of materials, and energy used in production and distribution has environmental benefits.

Eco-design

Term: A design strategy that focusses on three broad environmental categories – materials, energy, and pollution/waste.

- This makes eco-design more complex and difficult to do.

The Major Considerations of the United Nations Environmental Programme Manual on Eco- design

The UN released a manual on Eco design in 1996. It outlined major considerations:

- reduce the creation and use of toxic materials

- increase recyclability

- reduce energy consumption

- increase use of renewable resources

- increase product durability – reducing planned obsolescence

- reduce material requirements for products and services

The emphasis of the guidelines will vary depending on the type of product to be designed and the target market.

Timescale for Implementing Eco-design

- Some factors that can influence the timescale include:

- cost, available technology,

- radical or whole system overhaul,

- eco-design is more complex

- all of which can add to the timescale.

The “cradle to grave” and “cradle to cradle” Philosophy

Term: Cradle to Grave – A design philosophy that considers the environmental effects of a product all of the way from manufacture to disposal.

- It is a key principle of the linear economy.

|

|

|---|

Term: Cradle to Cradle – A design philosophy that aims to eliminate waste from the production, use and disposal of a product. It centres on products which are made to be made again.

- It is a key principle of the circular economy.

- Made to be made – is when a product is designed it is conceived in such a way that it can be made again using the same/most materials/resources of the original product, once it has been disposed of.

- Cradle to Cradle ® (C2C) is a holistic approach to design popularized by Professor Michael Braungart and William McDonough. Braungart and McDonough offer Cradle to Cradle ®certification to products that measure up to the standards they set.

- According to their website (www.c2ccertified.org): “The target is to develop and design products that are truly suited to a biological or technical metabolism, thereby preventing the recycling of products which were never designed to be recycled in the first place.”

Life Cycle Analysis (LCA)

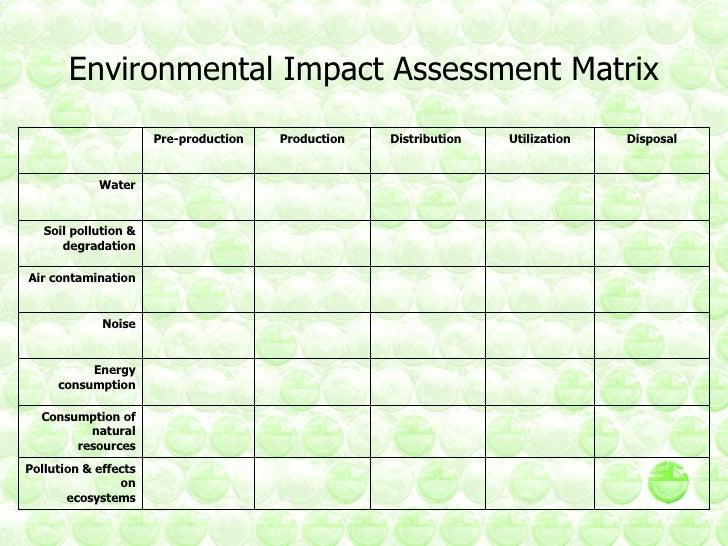

Term: The assessment of the effect a product has on the environment (LCA) through five stages of its life: pre-production; production; distribution (including packaging); utilization; and disposal.

- Designers use LCA to assess and balance environmental impact over a product’s life cycle.

- It can highlight areas with opportunities to reduce the environmental impact.

- It makes the designer to think about changing product design to reduce the impact such a green or sustainable product designs

LCA stages:

- pre-production;

- is the obtaining of natural resources;

- it can be very polluting (strip-mining) or can have a smaller effect on the environment (shaft mining),

- includes transporting the raw material to processing industries

- production

- is the processing of the resources and shaping etc. to make the product.

- Once again it could be damaging to the environment (such as a large factory spewing out smoke) or have a small impact (a carpenter hand crafting children’s toys)

- distribution including packaging;

- includes taking the product from the factory to the warehouse, from the warehouse to the store, and the package.

- It could have a large impact (as is the case with an imported object from around the world in a Styrofoam box) or a very low impact (made and sold in the same place with a biodegradable box or no packaging)

- utilization

- is about the product’s use and the effect that has on the environment.

- A diesel generator for example will pollute air and make noise pollution while a solar panel will make next to none.

- disposal

- depends on both the product and the method of disposal. Recycling one aluminum can will make less environmental problems than throwing one away even if they are identical.

- Biodegradable objects can be reused, recycled, or left to be broken down and add nutrients to the soil, depending on the object one or the other would be preferable.

- Paper is best recycled because of the chemicals used to make it and the logging of forests to obtain the pulp while a banana peel is completely useless for anything but compost.

Environmental considerations

- water and soil pollution

- water and soil degradation

- air contamination

- noise

- energy consumption

- consumption of natural resources

- pollution and effect on ecosystems.

t

Environmental Impact Assessment Matrix

The LCA matrix is a useful tool for designers of eco-products and systems.

LCA Matrix

LCA Matrix

- Benefits of organizing the life cycle stages and the environmental considerations into an environmental impact assessment matrix in which elements differ in importance according to the particular design context.

- It is targeted at particular product categories—products with high environmental impacts in the global marketplace, for example, washing machines and refrigerators.

- LCA identifies conflicts that have to be resolved through prioritization.

- It is not widely used in practice because

- it is difficult, costly and time-consuming.

- The complex nature of LCA means that it is not possible for a lone designer to undertake it and a team with different specialism is required.

- LCA is complex, time-consuming and expensive, so the majority of eco-designs are based on less detailed qualitative assessments of likely impacts of a product over its life cycle.

- However, in the re-innovation of the design of a product or its manufacture, specific aspects may be changed after considering the design objectives for green products, such as

- selecting less toxic materials or using more sustainable sources.

- a product may be distributed differently.

- its packaging may be redesigned.

- minimize the use of packaging.

- optimize energy efficiency in use.

- design for disassembly.

- minimize parts/components.

- use recyclable materials.

ENVIRONMENTAL AREA: AIR POLLUTION | ||||||

|---|---|---|---|---|---|---|

ACTIVITY | RISK IMPACT RATING (CIRCLE ONE NUMBER IN EACH ROW) | |||||

Pre-production: Transport of all materials to factory | 5 | 4 | 3 | 2 | 1 | 0 |

Production: Manufacturing process waste output | 5 | 4 | 3 | 2 | 1 | 0 |

Distribution: Transport of product to retailers | 5 | 4 | 3 | 2 | 1 | 0 |

Distribution: Manufacturing of packaging | 5 | 4 | 3 | 2 | 1 | 0 |

Utilization: Use of product during working life | 5 | 4 | 3 | 2 | 1 | 0 |

Disposal: Disassembly and recycling of materials | 5 | 4 | 3 | 2 | 1 | 0 |

Simple example of an environmental impact assessment matrix – from the IBO

- Environmental impact assessment matrices can be infinitely more complex, focusing on one particular stage of LCA at a time and breaking processes down into individual steps, often focusing on an output in terms of resources used, wasted and by-products generated and released.

- The simplest example is the use of a checklist to guide the design team during a product’s design development stages.

The roles and responsibilities of the designer, manufacturer and user at each stage of the product life cycle.

- Roles and responsibilities vary between them

- Clearly the user/consumer have little control in the early stages but more so in the products use and disposal.

- Similarly, with the designer and manufacturer.

Pre-production | Production | Distribution | Utilization | Disposal | |

|---|---|---|---|---|---|

Designer | Low | Mid-High | Mid-High | High | High |

Manufacturer | High | High | Mid | Low | Low |

User | Low | Low | Low | High | High |

Activity: Carry out a LCA on a washing machine and refrigerator.

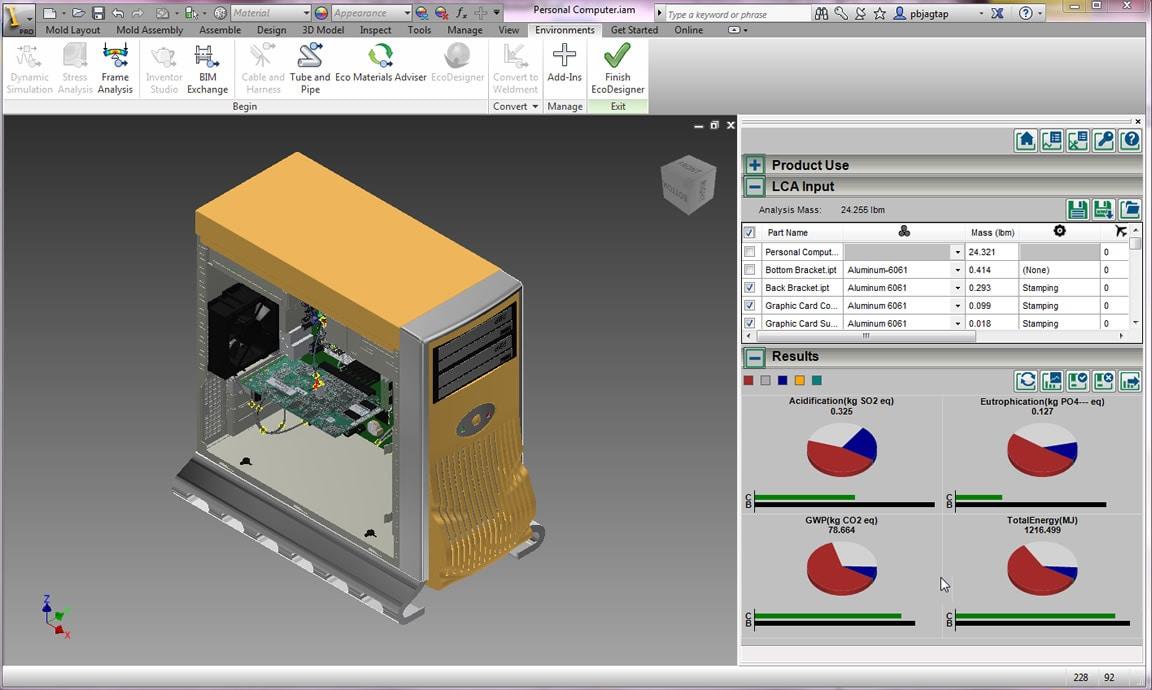

“Design for the Environment” (DfE) software

Term: Software that allows designers to perform Life cycle analysis (LCA) on a product and assess its environmental impact.

Eco-Designer LCA

Eco-Designer LCA

Design for the Environment description.

There is software available, such as Autodesk Inventor, Eco-designer or Solidworks that allows designers to DfE. They

- allow the designer to carry out LCA.

- select materials and manufacturing techniques that reduce environmental effects.

- run scenarios that can minimize materials.

- optimise designs to get cost effective products that are environmentally concerned.

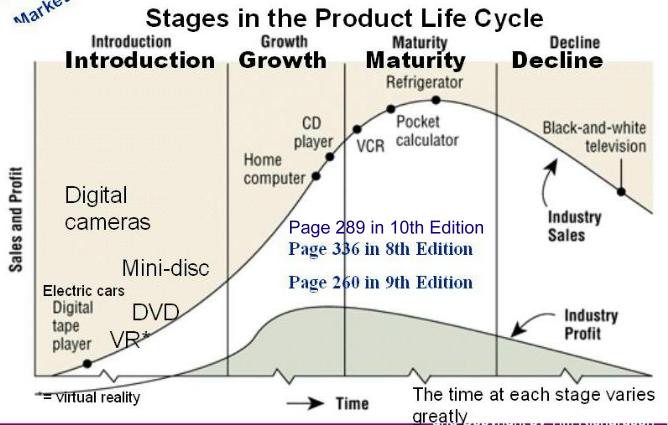

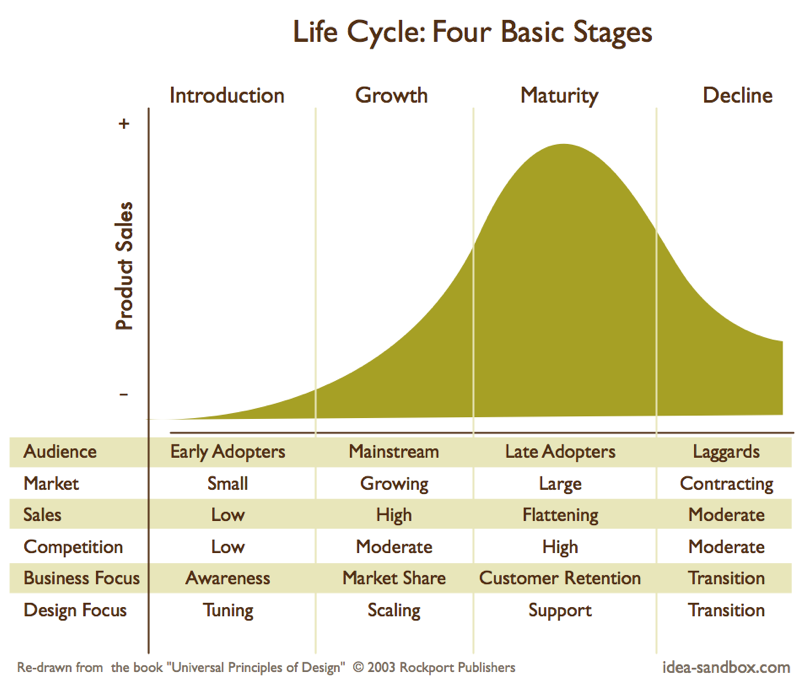

Product Cycle

Term: Product Cycle – Also known as the product life cycle, it is a cycle that every product goes through from introduction to withdrawal or discontinuation.

|

|

|---|

| Where is the computer mouse in he Product Life Cycle? – SMH Link to the article |

|---|

Four main stages

There are four main stages of the product life cycle which are, introduction, early, mature and late.

- During the early stages the product has just recently been introduced into the market and tends not to sell well and maybe overpriced in order to break-even. It also undergoes many changes.

- During the Mature stages of the product cycle the product is now reached its peak where little changes to its design occur and sells very well.

- During the late stage the product’s sales decline and becomes obsolete.

Designing is part of the product cycle.

- A need is generated and a product is designed, manufactured, and sold.

- Product eventually becoming obsolete (out of use).

- Distributors, retailers, accountants and production engineers, who all have an affect over the cycle, complicate the cycle.

- Unlike in the design process, the designer is not necessarily in control of the cycle.

- In CAD (computer aided design) and CAM (computer aided manufacture), the designer actually becomes part of the cycle by creating the prototype from a personal computer.

The role of the designer:

- Designing is part of the product cycle: as a need is generated, a product is designed, made and sold, eventually becoming obsolete.

- The cycle is complicated by distributors, retailers, accountants and production engineers, all of whom have an influence over the cycle. Although the designer is an integral part of the process, he or she is not necessarily in control (unlike in the design process).

- Computer-aided design (CAD) and computer aided manufacture (CAM), where a prototype is produced by the designer from his or her personal computer (PC), blurs this distinction.

The role of the manufacturer

- In the selection of manufacturing techniques – preferably limiting environmental affect – injection moulding produces very little waste

- Quality control – controlling errors and waste

- Specify standrad components and sub-assesmblies

- Attempt to minimise: energy usage, emissions, water pollution and other elements of the LCA.

- This can be done through the introduction of management systems.

The role of the user

- Market pull from consumers

- Spending patterns – a need for a durable product versus a disposable one

- Disposal of the product

- Consumers can force designers and manufacturers to be more green usually through their buying power

- Provide feedback to manufacturers

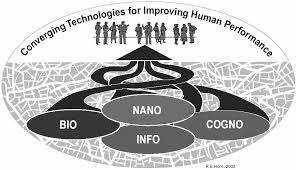

Converging Technologies

Term: The synergistic merging of nanotechnology, biotechnology, information and communication technologies and cognitive science.

|

|

|---|

Advantages | Disadvantages |

|---|---|

|

|

- An example of converging technology is the smart phone.

- consider the smart phone as a converging technology in terms of the materials required to create it, its energy consumption, disassembly, recyclability and the portability of the devices it incorporates.

- Functionality: telephone. texting, apps, MP3 Player, video and still camera, phone book, etc

- Other examples include mobile health devices such as the FitBit or iWatch or other wearables that have integrated circuits that can monitor body functions.

- Wareable Article

- Digital Trends on wearables

Knowt

Knowt

How a grid works

How a grid works Asia Pacific Power Grid

Asia Pacific Power Grid Italian National Grid

Italian National Grid Food Carbon Footprint

Food Carbon Footprint Global Carbon Footprint

Global Carbon Footprint First Chemical Battery

First Chemical Battery

Carbon Capture

Carbon Capture Clean Technology

Clean Technology No Environmental Protection

No Environmental Protection Cradle to Cradle – Circular Economy

Cradle to Cradle – Circular Economy Cradle to Grave – Linear Economy

Cradle to Grave – Linear Economy Product Life Cycle (a bit dated!)

Product Life Cycle (a bit dated!) Product Life Cycle and Marketing

Product Life Cycle and Marketing Converging Technology

Converging Technology Converging Technology

Converging Technology