MOD 4 - Digital Imaging Process

Computed Radiography

= exposure of an imaging receptor in a cassette and a computer system for image processing

both are digital (not film)

uses IP

CR Imaging Receptor / Cassette

= lightweight tight plastic container that protects the digital imaging plate from damage from handling

backed by a thin sheet of Al that absorbs x-rays

front or tube side of the cassette is constructed of a radiolucent carbon fibre

also contains an antistatic material that protects against static electricity build up, dust collection and mechanical damage to the IP

Cassette

the backside contains brackets and hinges

only use front side when imaging

main function is to protect the IP from damage

however, it can’t protect the IP from light damage bc its not sensitive to light

CR Imaging Plate

capable of storing an image formed by the incident x-ray photon (a single x-ray in the primary x-ray beam that is traveling towards the interested part) that excites the photostimulable phosphors (PSP: materials that store energy from X-rays and gamma rays and release it as light when stimulated)

Composition of IP

PSP are deposited in layers on the imaging plate

common PSP materials:

europium activated fluorohalide crystals

cesium bromide crystals

Europium: element that allows for energy storage

*ability of the PSP to retain energy is time limited, THEREFORE IPs should be processed soon after exposure *

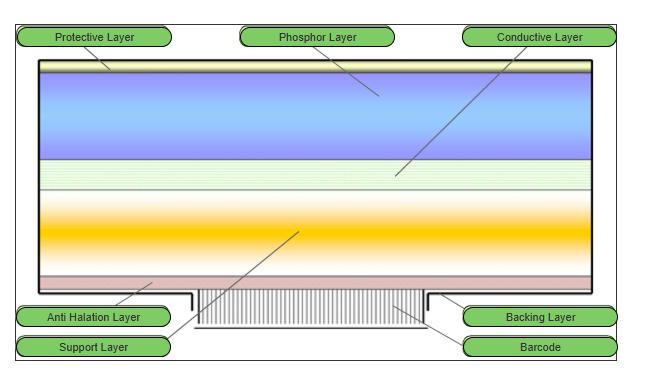

CR IP Layers

Protective Layer

thin, tough, clear plastic top layer

protects the underlying phosphor layer and rest of IP

improves the signal to noise ratio of an image

Phosphor layer / F-Center / storage phosphor / colour layer

active layer of the IP as it traps/stores the -e when struck by x-rays

may contain a dye to absorb the stimulating light to prevent as much spread

phosphor gradually releases stored energy naturally (phosphorescence) but this is acc during processing by the exposure to intense infrared laser light (photostimulated luminescence - PSL)

made up of barium fluorohalide or cesium bromide crystals, europium azelcleaer (?)

Light reflective layer

below phosphor layer and reflects light

reflects and focuses the light heading to the back of the IP to the crystal structure in the phosphor layer

energy is bounced back to the crystal structure (phosphor layer)

Conductive Layer

absorbs and reduces static electricity that can cause light emission (light emission can produce artifacts or a false image)

Supportive Layer

semi-rigid material that gives the imaging plate some strength

constructed of a polymethylene terephthalate (PET) base- a strong, pliable plastic

Colour or Anti-halation Layer

consists of a blue tinted dye that absorbs unwanted stimulating laser light while reflecting emitted light

Backing Layer

soft, plastic layer constructed of a soft polymer that also serves to protect the base of IP from damage during processing (as the IP is removed from the cassette to be processed)

Barcode

allows the user to match the image information with the RIS patient demographics

CR Image Formation Steps

Expose

phosphors of the IP retains energy based on the frequency and number of photon interactions

Stimulate

cassette is inserted into the CR reader

the IP is removed from the IR

a laser scans the IP to release the energy stores as bursts of light (photostimulable luminescence- PSL)

light emitted is converted into an electrical signal

Read

electrical signal is detected by PMT and measured, then converted to a digital signal by ADC (analog-to-digital converter) and digitized to be displayed on the workstation monitor

Erase

then the IP is erased by exposure to intense light that releases any retained energy (causes it to return to ground-state energy level)

not all areas can be erased, some portions will be missed

CR receptor is ready for reuse

CR Processor / Reader

= designed to process a single cassette perhaps within a radiography room or multiple cassettes in a hub of multiple x-ray rooms

CR Processing Steps

exposure of CR plate

scan barcode of CR plate at workstation to associate to patient exam

insert plate into CR processor

imaging plate processed

IP removed, scanned by laser,

light emitted detected by photomultiplier tube (PMT)

PMT analog signal converted to digital signal (analog-to digital-conversion)

digital signal transmitted to monitor viewing station

IP exposed to intense light to release any residual energy stored in phosphors

IP inserted into cassette and ejected from CR processor, ready to reuse

dark features = energy absorbed by IP

white features = energy blocked, absorbed by bone/parts

Direct Radiography

= more streamline, does not require a separate processing step

both digital

flat-panel detectors

uses a large area active-matrix array of electronic components

two image production methods for DR

direct conversion

uses photoconductor

indirect conversion

scintillator material

high sensitivity of CsI → significant exposure reductions → substantially reduce patient dose

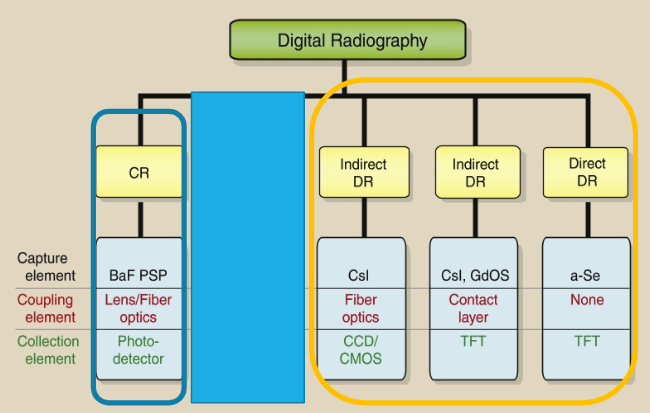

Three elements to all digital radiography

Capture element (crystal structures that absorb energy, creates light)

Coupling element (layer that binds the light produced to a collection system)

Collection element (reads the light produced which is read by chips or in an amorphous silicon)

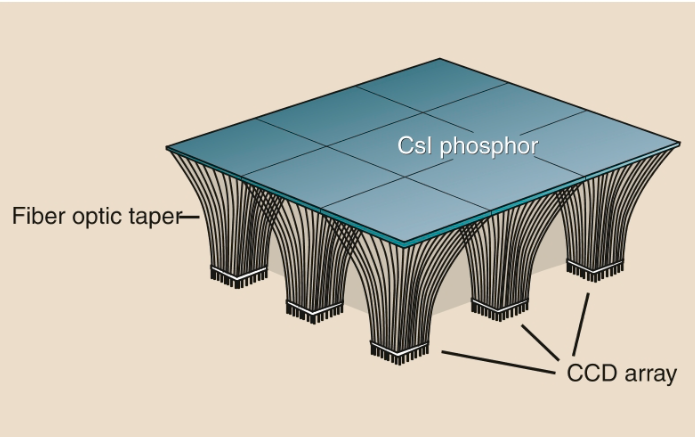

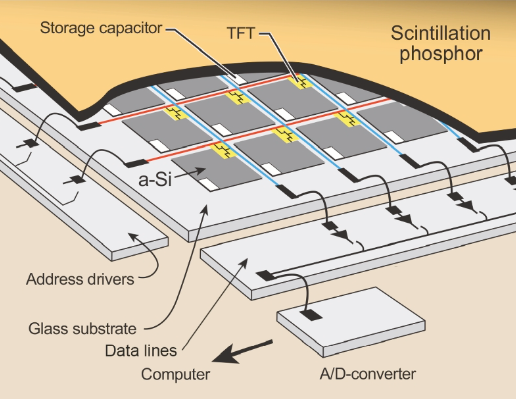

Indirect DR Detectors

= system absorbs x-rays and first converts it to light before creating a digital signal

Scintillating (light producing) materials (cesium iodide) are used to convert photon energy into visible light

The light is detected and converted to an electrical signal that is sent to the computer for processing

Two methods for this light conversion

charge-coupled device (CCD)

thin-film transistor (TFT)

Direct DR Detectors

no scintillation layer (no CsI) involved, therefore no light-emitting process that is detected and amplified

x-ray photon energy/exit radiation is directly (by a-Se) converted to electrical energy/electrical charges

this system relies on a layer of amorphous selenium (a-Se) for both the capture element and the coupling element

Electrical signals are sent to the ADC for digitization

Post Processing Functions

image control quality

includes a thorough critique of each image, as well as post-processing if necessary

Examples of Post Processing

annotation (markers, position)

zoom (zoom data is not saved, just for viewer instance)

image flip

image rotation (to correct orientation)

window level/width (adjusting the grey scales and contrast to improve visualization, this adjusted image must not be sent to PACS for diagnosis)

measurement (for length or volume of a structure)

Knowt

Knowt