6. Colloidal instability, flocculation and rheology of dispersions

Instability in colloidal dispersions

- Sedimentation

- Creaming

- Flocculation (aggregation)

- Ostwald ripening

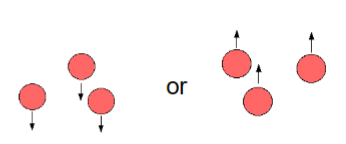

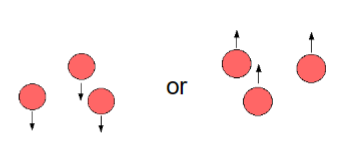

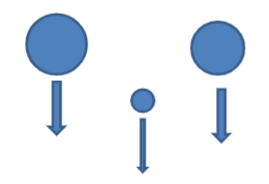

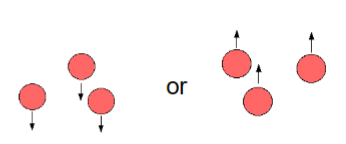

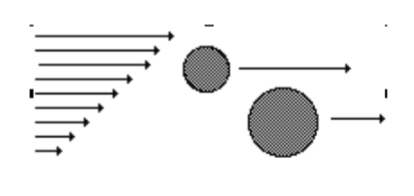

Sedimentation- Particle density is higher than the density of continuous phase → particles sink

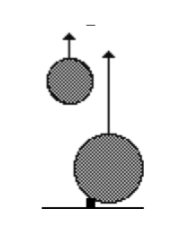

Creaming- Particle density is lower than the density of continuous phase → particles rise to surface

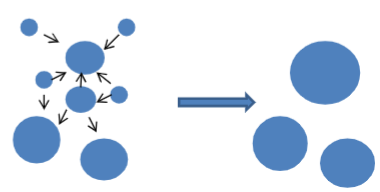

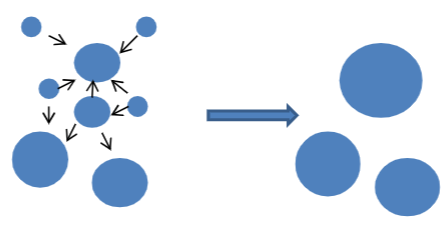

Flocculation (aggregation)- a process where a solute (particles) comes out of solution in the form of floccules due to insufficient repulsion between particles

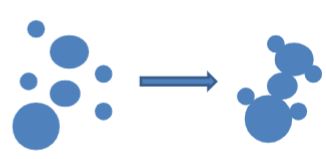

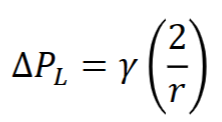

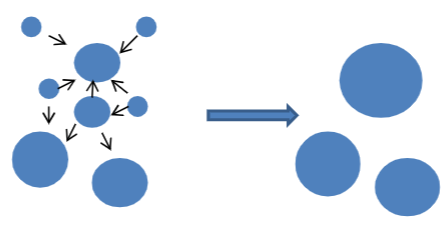

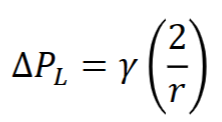

Ostwald ripening- Large particles grow at the expense of smaller ones. Depends on how soluble dispersed phase is in continuous phase

Smaller droplets → higher la place pressure → higher driving force

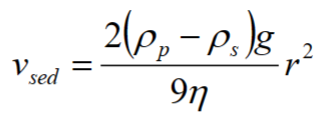

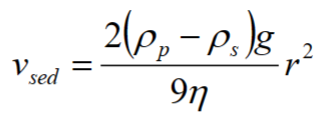

Sedimentation

Stokes’ law

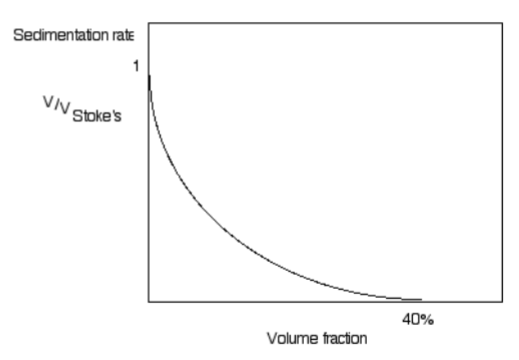

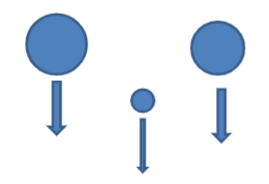

Low concentration (φ<5%): vsed = vStokes

For dispersion by particles is 25%

High concentration: (φ>5%): vsed< vStokes

Sedimentation rates are lower than Stoke’s law predict

Hindered sedimentation/creaming- The sedimentation or creaming rate decreases with increasing concentration of the dispersed phase.

When we have more 40% sedimentation doesn’t occur since there is no space, the particles are too crowded

Flocculation- depends on properties of surfactants

Mechanisms:

• Brownian motions

The particles get close to each other through random movement

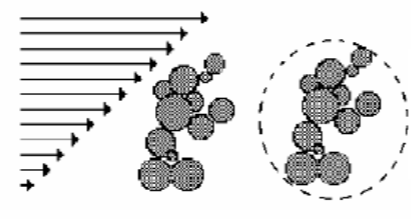

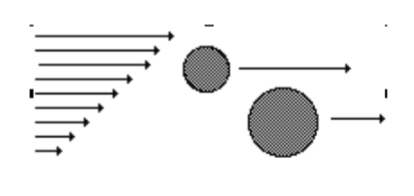

• Shear induced flocculation

Some particles experience higher or lower shear stress depending on their surface

• Gravitity induced flocculation

Shear induced flocculation

• Do not include:

• The ”lubricating” properties of the liquids

• The shear sensitivity of the aggregates

• Interactions

• Brownian motions

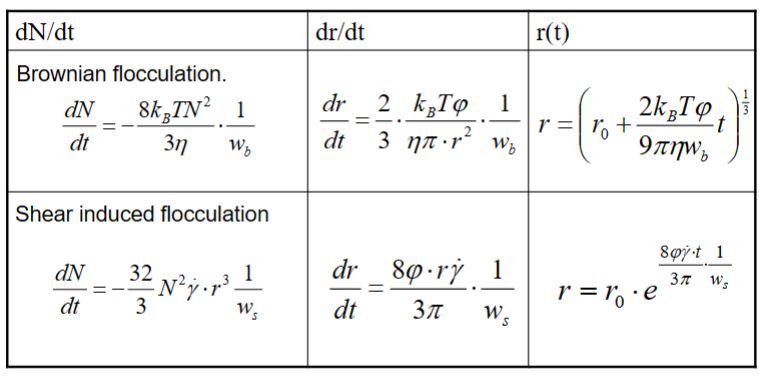

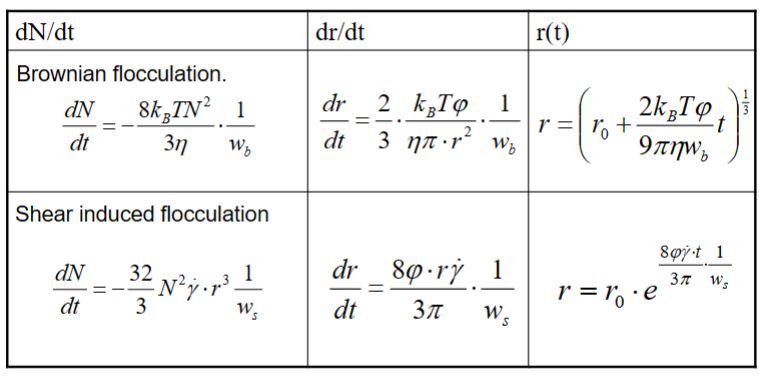

Comparison between Brownian and shear flocculation rate

N = number concentration of particles, kB = Boltzmann constant, T = absolute temp., η =

dynamic viscosity, w = stability factor, φ = volume fraction of particles, γ = shear rate

Stability factor

w=1 → each collision leads to aggregation (high possibility of flocculation)

w=106 → one collision in a million leads to aggregation

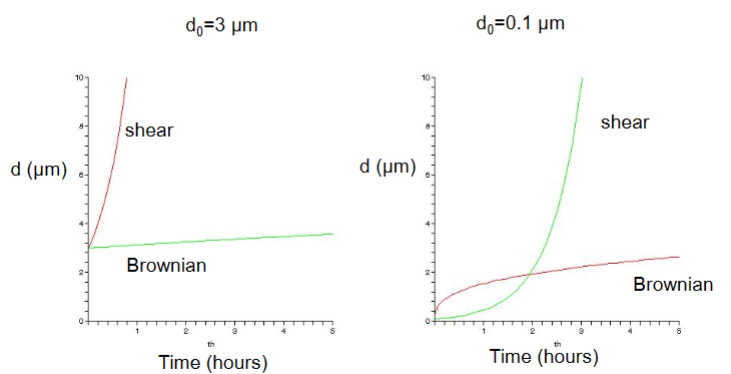

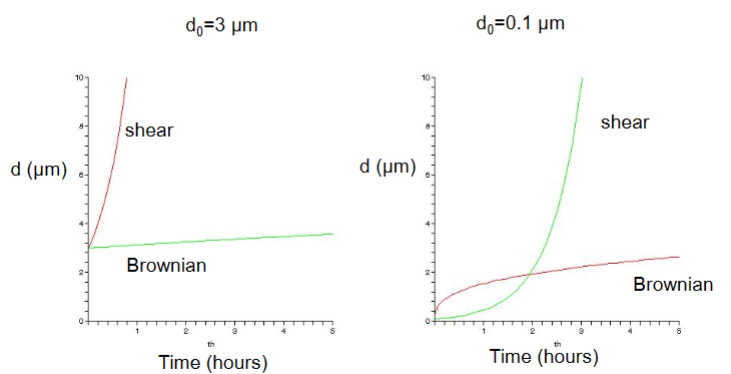

Comparison between shear and Brownian flocculation

do= particle size at time 0

Small particles= flocculation is rapid

do=0.1 μm

Small particles flocculate quickly due to Browian but then it is too big and slow down

Brownian: Initially rapid, but then slowly

Shear: In the beginning, it is slow, but then rapidly increases

do=3 μm

Shear: Rapid growth of particle size. Large and likely to meet than small particles in shear-like movement.

Browian: Slow. Larger particles have a slower diffusion so it takes them longer to randomly meet

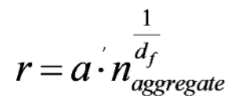

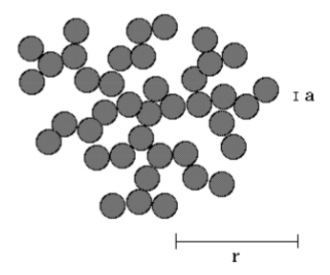

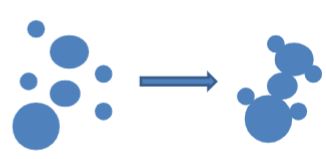

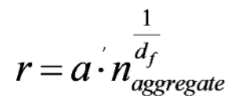

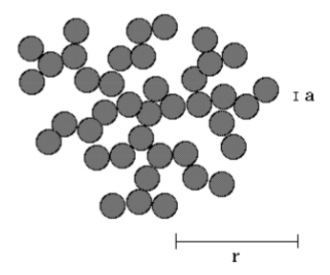

Fractal aggregates (flocs)

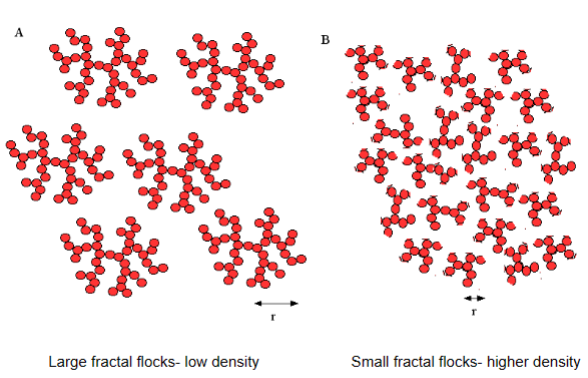

• Aggregates that occupy a larger volume than the individual particles are called fractal aggregates or flocs

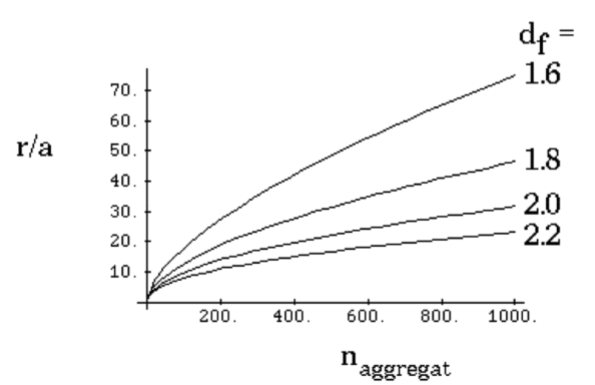

• The size of the flocs is described by the fractal dimension df

naggregate = the number of particles in the aggregate

a=radius of one particle

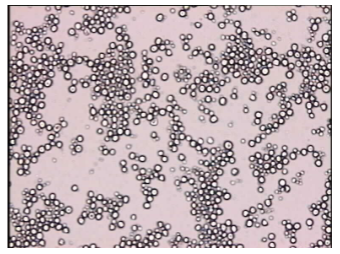

Example of fractal aggregate

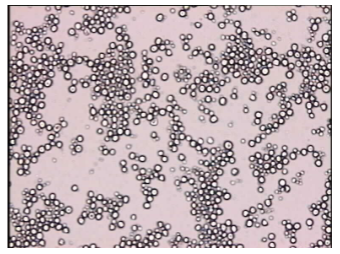

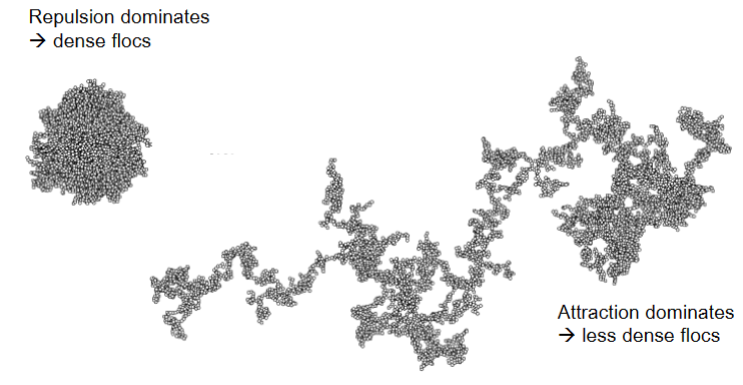

• Oil-in-water emulsion produced using membrane emulsification.

Force an oil phase though a membrane with small pores?

Emulsifier not efficient?

Doesn’t give enough repulsion between oil droplets?

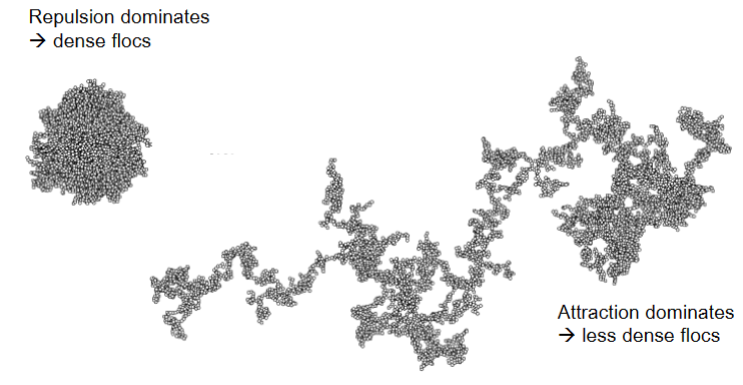

Attraction is dominating in the picture below. Loose, string-like structures

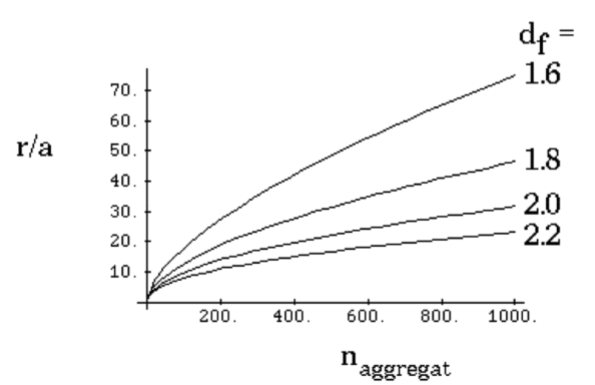

Radius of fractal aggregates

The lower the fractal dimension, larger the fractal aggregate radius will be → more continuous phase present?

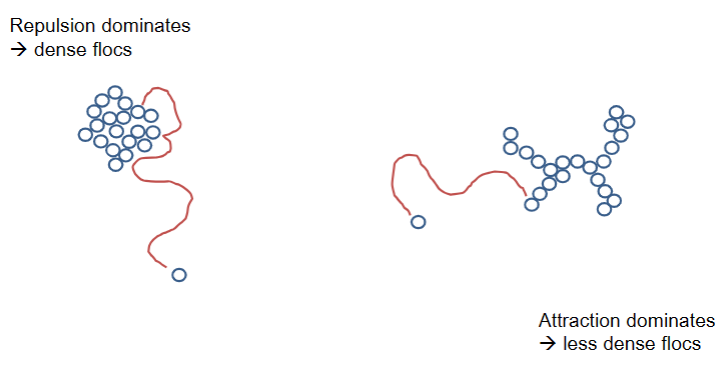

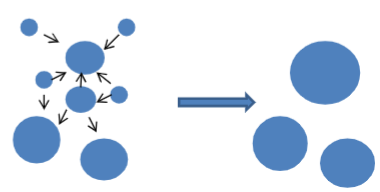

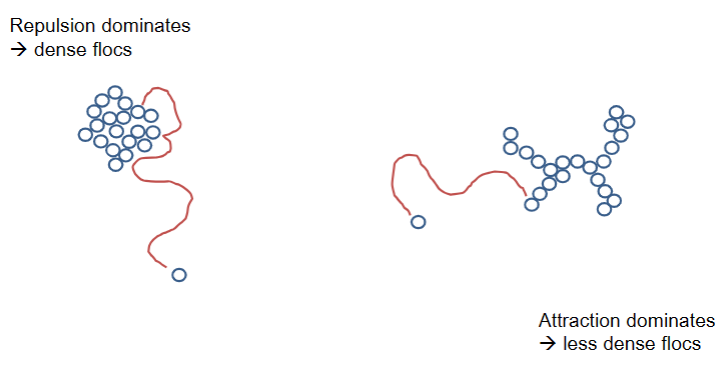

Interactions and aggregate structure

Repulsion dominates → dense flocs

- relatively weak repusion

- Drying - removal of solvent → Forces them together by moving continuous phase

Attraction dominates → less dense flocs

Cheese

Cleared and attraction dominates when pressed

Fractal structure forms as there’s very little control as to what is going on

Like the last slide

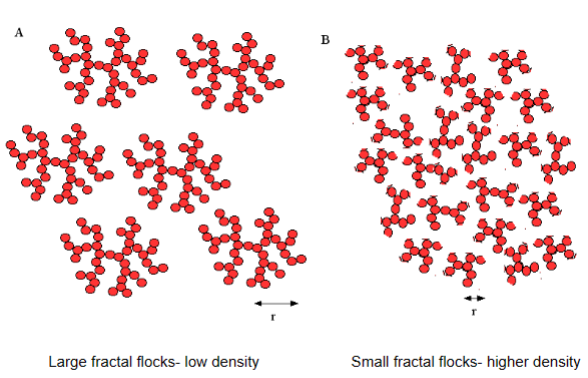

Large fractal flocks - low density

Larger but density lower → more rapid sedimentation

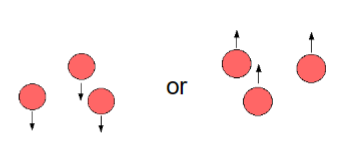

Ostwald ripening

• Driven by the Laplace pressure

• Molecules from smaller particles dissolve and diffuse to larger particles

• Occurrence and rate also depend on the solubility disperse phase molecules in the continuous phase

– Low solubility slows it down or inhibits it

• Also referred to as ”disproportionation” in foams

We have pressure and high surface tension. We need solubility

If this has low solubility in the continuous phase, process slowed down

Examples

• Waste water treatment.

• Ceramic materials.

• Cheese curd.

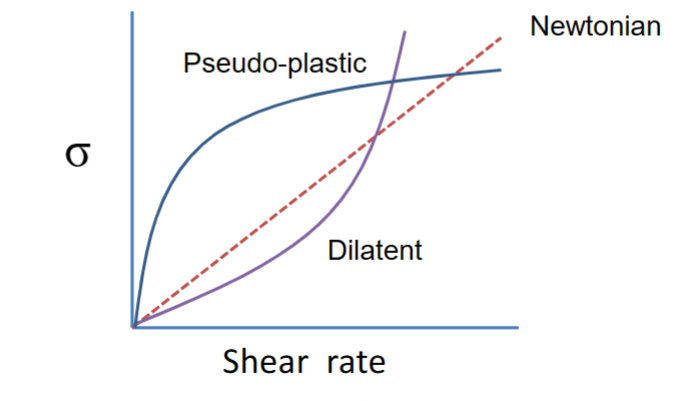

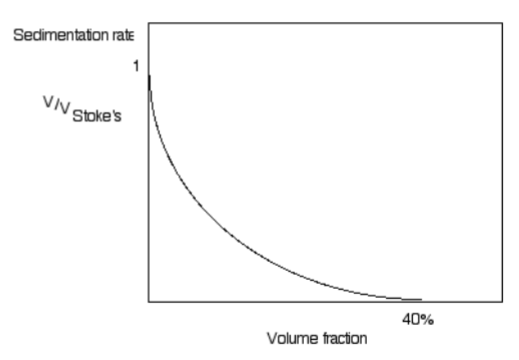

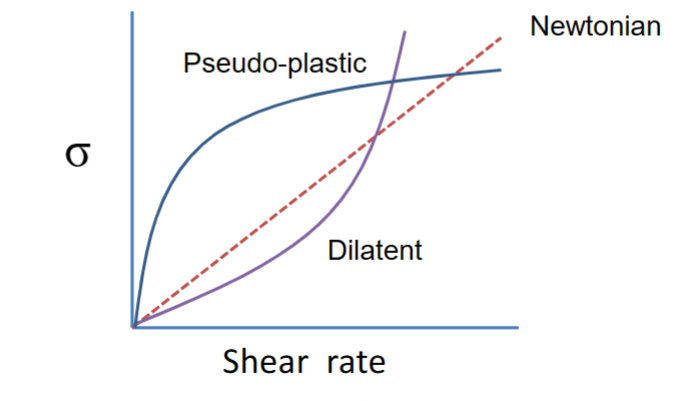

Non-Newtonian flow

Non-newtonian behaviour arises from disturbances in the flow pattern caused by sample components

Viscosity decreases as shear rate increases?

Dispersions commonly display shear-thinning flow beahviour

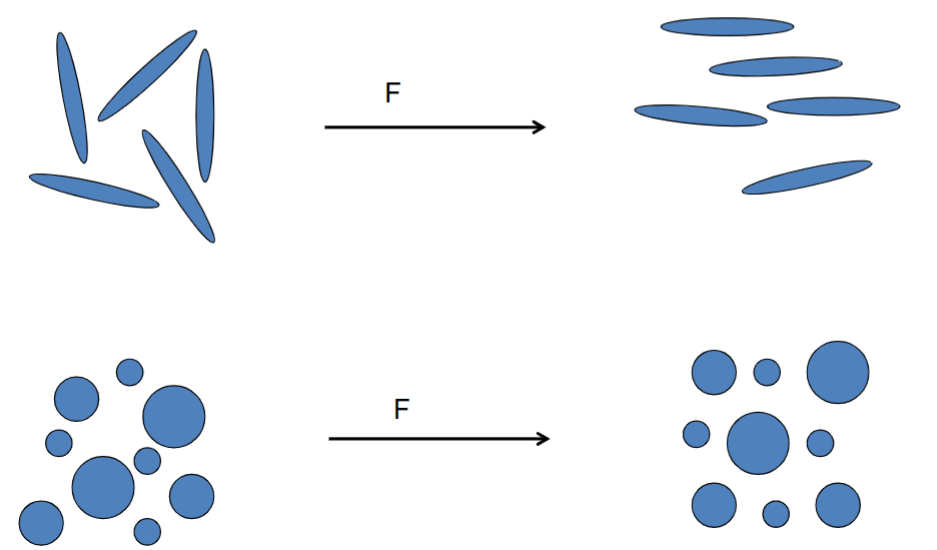

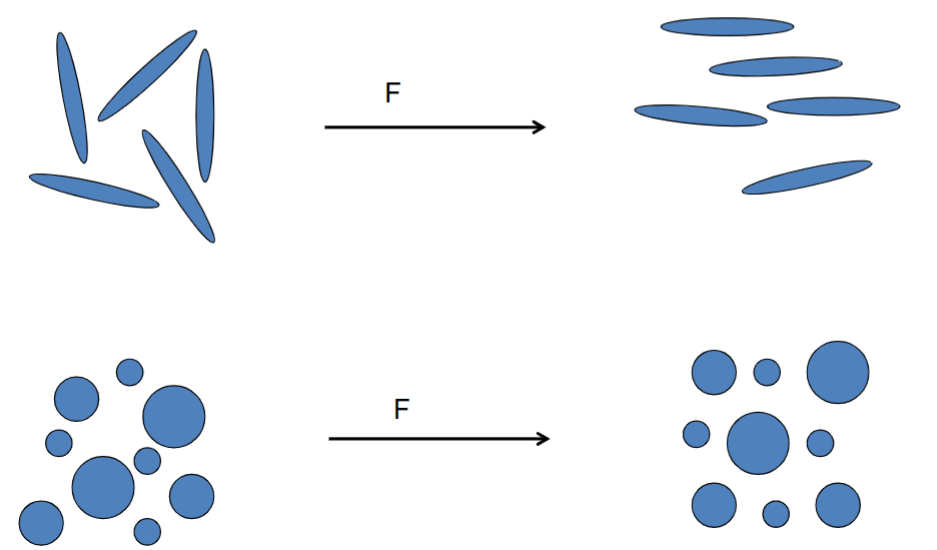

Orientation of particles in the flow

What happens to the viscosity?

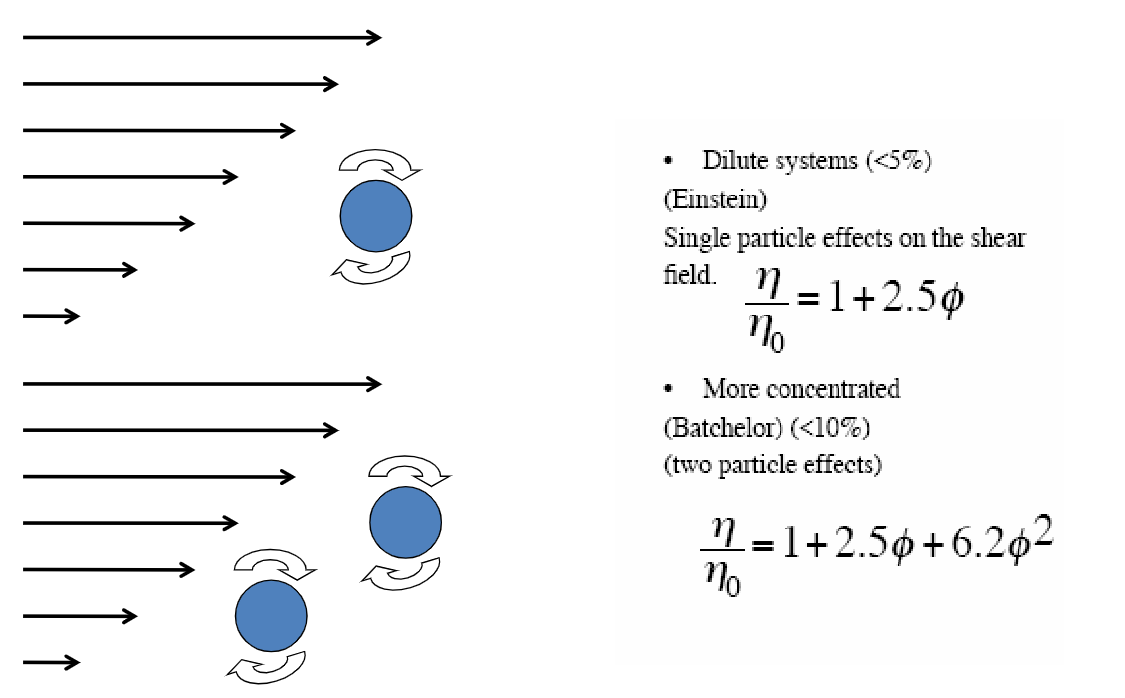

Dispersion rheology

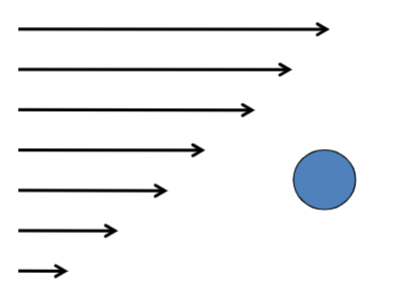

Higher viscosity is the result of particles disturbing the applied flow field and particles ”bumping into each other”.

In pure liquids: viscosity is the result of friction between molecules.

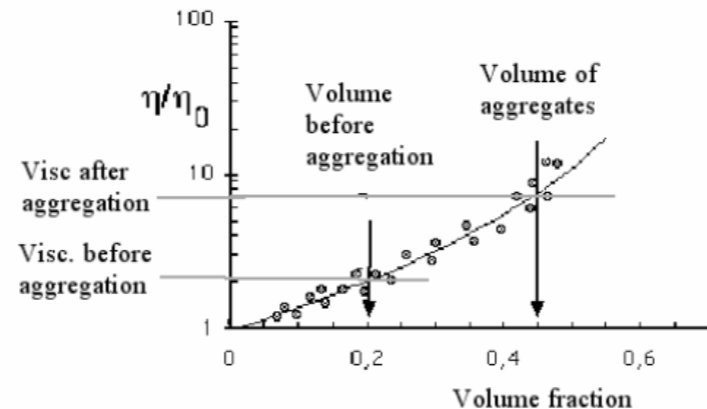

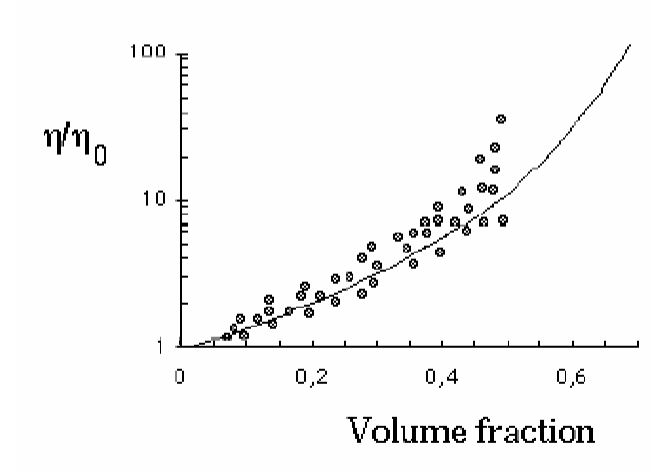

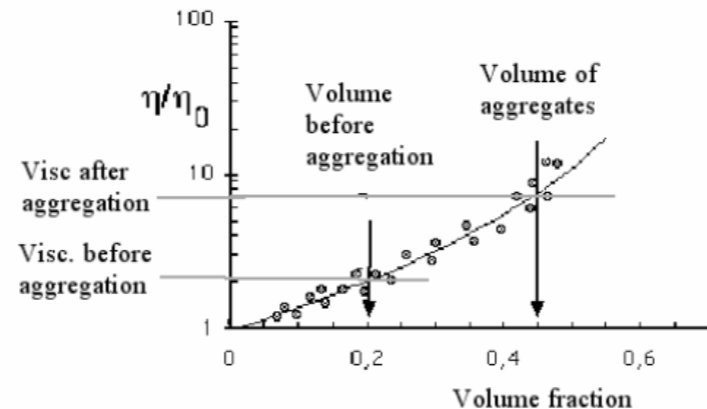

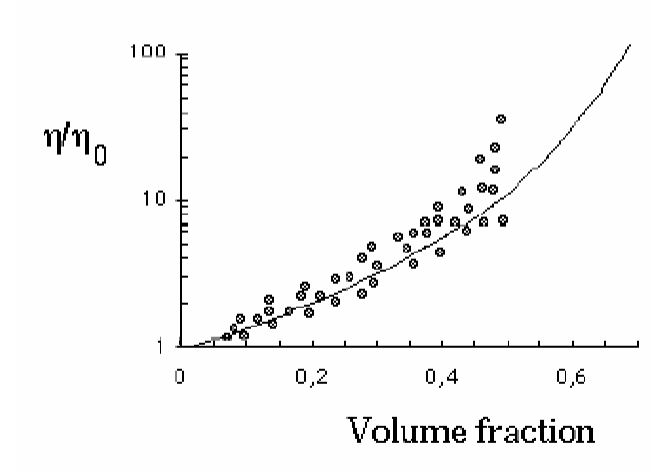

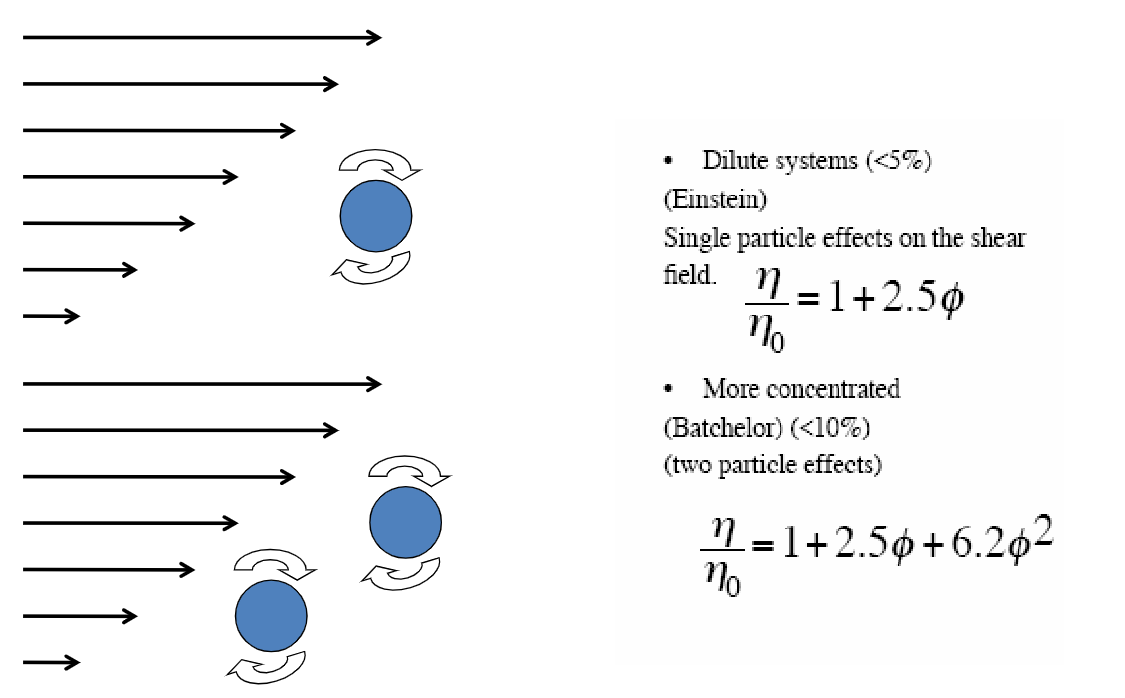

Volume fraction dependence

Relative viscosity vs. volume fraction of particles.

The first is single particle distortion flow

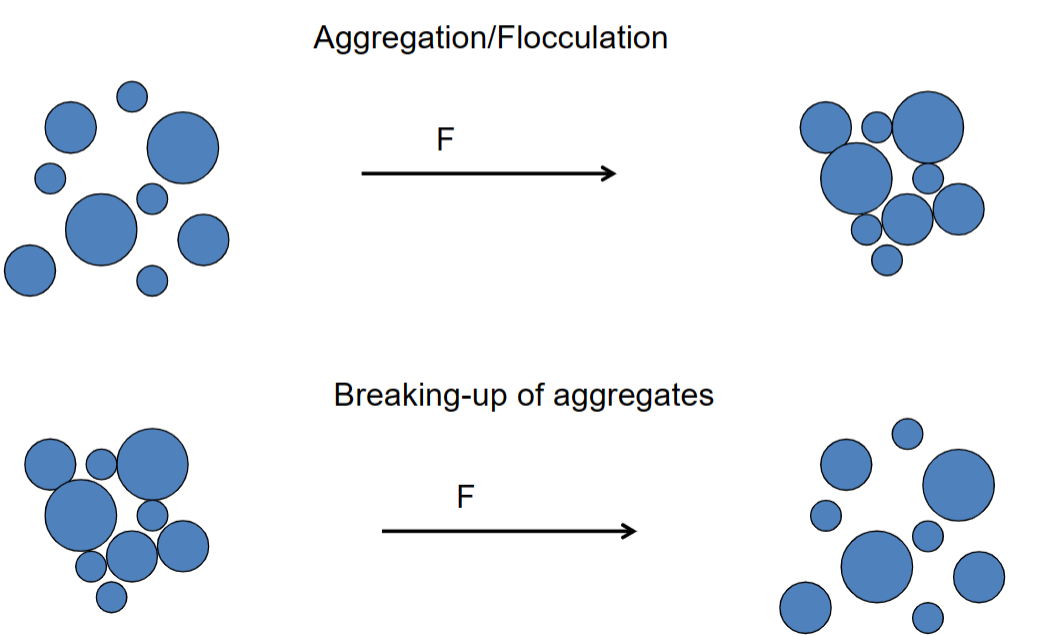

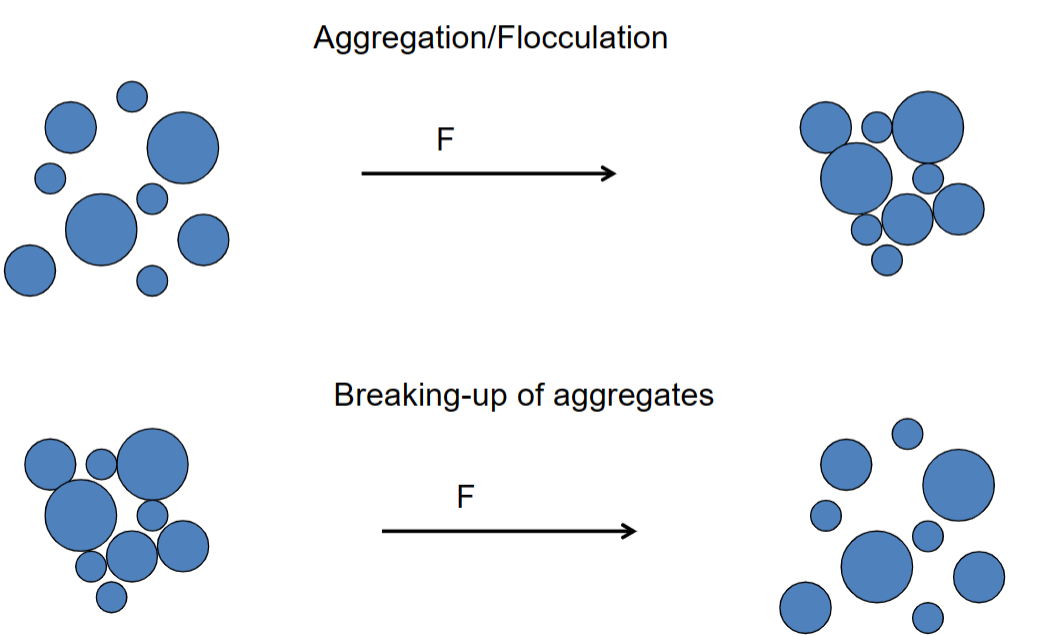

Creation/breaking-up of structures –How does it influence the viscosity?

- Friction between particles

Aggregation/Flocculation:

- Dispersed particles in continuous phase

- Flocculation occurs → Viscosity decreases

Breaking up aggregates:

- More particles flowing around bumping into each other → Viscosity increases

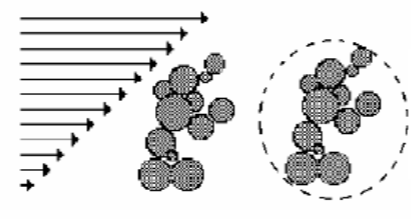

Effects from particle interactions

Repulsive interaction → increase in viscosity (at low shear rates).

Attractive interaction: The effective volume of an aggregate can be larger than the actual aggregate

6. Colloidal instability, flocculation and rheology of dispersions

Instability in colloidal dispersions

- Sedimentation

- Creaming

- Flocculation (aggregation)

- Ostwald ripening

Sedimentation- Particle density is higher than the density of continuous phase → particles sink

Creaming- Particle density is lower than the density of continuous phase → particles rise to surface

Flocculation (aggregation)- a process where a solute (particles) comes out of solution in the form of floccules due to insufficient repulsion between particles

Ostwald ripening- Large particles grow at the expense of smaller ones. Depends on how soluble dispersed phase is in continuous phase

Smaller droplets → higher la place pressure → higher driving force

Sedimentation

Stokes’ law

Low concentration (φ<5%): vsed = vStokes

For dispersion by particles is 25%

High concentration: (φ>5%): vsed< vStokes

Sedimentation rates are lower than Stoke’s law predict

Hindered sedimentation/creaming- The sedimentation or creaming rate decreases with increasing concentration of the dispersed phase.

When we have more 40% sedimentation doesn’t occur since there is no space, the particles are too crowded

Flocculation- depends on properties of surfactants

Mechanisms:

• Brownian motions

The particles get close to each other through random movement

• Shear induced flocculation

Some particles experience higher or lower shear stress depending on their surface

• Gravitity induced flocculation

Shear induced flocculation

• Do not include:

• The ”lubricating” properties of the liquids

• The shear sensitivity of the aggregates

• Interactions

• Brownian motions

Comparison between Brownian and shear flocculation rate

N = number concentration of particles, kB = Boltzmann constant, T = absolute temp., η =

dynamic viscosity, w = stability factor, φ = volume fraction of particles, γ = shear rate

Stability factor

w=1 → each collision leads to aggregation (high possibility of flocculation)

w=106 → one collision in a million leads to aggregation

Comparison between shear and Brownian flocculation

do= particle size at time 0

Small particles= flocculation is rapid

do=0.1 μm

Small particles flocculate quickly due to Browian but then it is too big and slow down

Brownian: Initially rapid, but then slowly

Shear: In the beginning, it is slow, but then rapidly increases

do=3 μm

Shear: Rapid growth of particle size. Large and likely to meet than small particles in shear-like movement.

Browian: Slow. Larger particles have a slower diffusion so it takes them longer to randomly meet

Fractal aggregates (flocs)

• Aggregates that occupy a larger volume than the individual particles are called fractal aggregates or flocs

• The size of the flocs is described by the fractal dimension df

naggregate = the number of particles in the aggregate

a=radius of one particle

Example of fractal aggregate

• Oil-in-water emulsion produced using membrane emulsification.

Force an oil phase though a membrane with small pores?

Emulsifier not efficient?

Doesn’t give enough repulsion between oil droplets?

Attraction is dominating in the picture below. Loose, string-like structures

Radius of fractal aggregates

The lower the fractal dimension, larger the fractal aggregate radius will be → more continuous phase present?

Interactions and aggregate structure

Repulsion dominates → dense flocs

- relatively weak repusion

- Drying - removal of solvent → Forces them together by moving continuous phase

Attraction dominates → less dense flocs

Cheese

Cleared and attraction dominates when pressed

Fractal structure forms as there’s very little control as to what is going on

Like the last slide

Large fractal flocks - low density

Larger but density lower → more rapid sedimentation

Ostwald ripening

• Driven by the Laplace pressure

• Molecules from smaller particles dissolve and diffuse to larger particles

• Occurrence and rate also depend on the solubility disperse phase molecules in the continuous phase

– Low solubility slows it down or inhibits it

• Also referred to as ”disproportionation” in foams

We have pressure and high surface tension. We need solubility

If this has low solubility in the continuous phase, process slowed down

Examples

• Waste water treatment.

• Ceramic materials.

• Cheese curd.

Non-Newtonian flow

Non-newtonian behaviour arises from disturbances in the flow pattern caused by sample components

Viscosity decreases as shear rate increases?

Dispersions commonly display shear-thinning flow beahviour

Orientation of particles in the flow

What happens to the viscosity?

Dispersion rheology

Higher viscosity is the result of particles disturbing the applied flow field and particles ”bumping into each other”.

In pure liquids: viscosity is the result of friction between molecules.

Volume fraction dependence

Relative viscosity vs. volume fraction of particles.

The first is single particle distortion flow

Creation/breaking-up of structures –How does it influence the viscosity?

- Friction between particles

Aggregation/Flocculation:

- Dispersed particles in continuous phase

- Flocculation occurs → Viscosity decreases

Breaking up aggregates:

- More particles flowing around bumping into each other → Viscosity increases

Effects from particle interactions

Repulsive interaction → increase in viscosity (at low shear rates).

Attractive interaction: The effective volume of an aggregate can be larger than the actual aggregate