Test 3: Supply Chain Ch. 9-12 Notes

Chapter 9: Logistics: Warehousing, Transportation, and Reverse Logistics - 46%

Warehousing

having the right product in the right place at the right time

Warehousing provides time and place utility

Availability necessary to give materials true value

Warehouse - Facility used to store purchases, work-in-process (WIP), and finished goods inventory

Warehousing - Function that allows a company to receive, store, breakdown, repackage, and distribute items to a manufacturing location, or finished products to a customer

Decisions driving Warehouse Management include:

Number of warehouse facilities in the network

Site selection

Layout of the warehouse(s)

Methods of receiving, storing, retrieving, and distributing products and materials

Ex.: manual, semi automated, fully automated

Primary functions of a warehouse

Receiving - Physical receipt of material, identification, inspection for conformance with the purchase order (quantity and damage), put-away, and preparation of receiving reports

Storage - The safe and secure retention of parts or products for future use or shipment

Picking - Withdrawing components from stock to make assemblies or finished goods, or to ship to a customer

Packing - Placing one or more items of an order into an appropriate container for safe shipping , and marking and labeling the container with customer shipping destination data, and other information that may be required

Shipping - Outgoing shipment of parts, components, and products. Includes packaging, marking, weighing, and loading for shipment

Does NOT include transportation

Warehouse ownership types

Public warehouses

Contract warehouses

Private warehouses

Public warehouse

A business that provides storage and related warehouse functions to companies on a short or long-term basis, generally on a month-to-month basis for a fee.

Own their own equipment and hire their own staff to manage the facility.

Fees are typically a combination of a monthly storage fee plus a pallet-in fee and a pallet-out fee.

Fees will vary based on what is being stored and/or based on:

Size and weight of the pallets

If they can be stacked

How fragile the product is

Value of goods (risk of theft)

Hazards associated with the goods

May also have some document fees and account management fees

Think of it as a hotel for inventory

Advantages

No capital investment or property taxes

Flexibility:

Can be short or long term contract

For seasonal products

Add storage capacity even on short notice

Lower costs and reduced risk

Access to special features and services:

Temperature-controlled storage

Customer Service, Inventory Ordering, etc.

Office space for customer’s sales, accounting, etc.

Disadvantages

Potential for incompatible computer systems

Specialized services may not be what is required/needed

Space may not be available when/where needed

Contract warehouse

A variation of public warehousing that handles the shipping, receiving, and storage of goods on a contract basis for a fee

Contract can be used for entire building or for a defiend portion within a building

Usually requires a client to commit to services for yearsrather than months

The fee structure may be fixed cost, cost-plus, or a combination of both.

The company providing the space handles the employees, equipment, and maintenance.

Think of it as renting an apartment for inventory

Many advantages and disadvantages of a public warehouse also apply to contract warehousing

Advantages

Services: client can obtain specialized services tailor-made to suit their needs.

Cost: can be bundled in the contract and negotiated at a lower cost.

Control: contract warehousing offers a degree of control at a reasonable price

Disadvantages

Duration: The client company is expected to enter into a contract for a specific period of time; generally three years.

Private warehouse

Private warehouse - A storage facility that is owned by the company that owns the goods being stored in the facility

Generally established by companies that have a large volume or highly valuable goods, or the need for some type of specialized storage or handling.

Can be operated as a separate division within a company

Can be co-located on-site with manufacturing, or off-site

Think of it as buying a house for inventory

Advantages

Control: Offers greater flexibility in designing the warehouse and gives users significant control over operations.

Visibility: inventory, material flow, handling, supervision, and associated costs.

Cost: Operating cost can be 15% -25% lower if the company achieves at least 75% utilization

Disadvantages

High Start-up Cost: Capital to build or buy a warehouse. Long, risky investment. Cost of hiring and training employees. Purchase of material handling equipment.

Fixed Location: Not easy to move to another location if the market changes.

Fixed Size and Costs: When volume is low, the company still assumes the fixed costs

Types of Warehouses

Consolidation

Break-bulk

Cross-docking

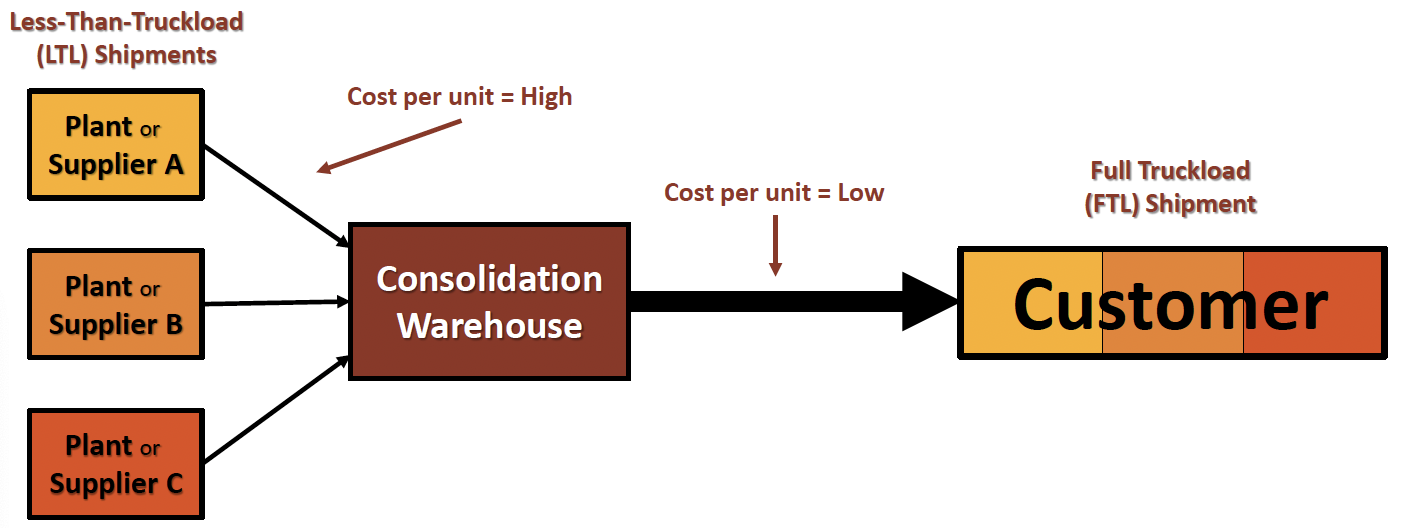

Consolidation warehouse

Warehouse operation that receives products from different plants or suppliers, stores them, and then combines them with similar shipments from other plants or suppliers for further distribution

Located closer to the supply base so that smaller LTL shipments travel shorter distance and can be consolidated into larger FTL shipments traveling longer distance to the customer

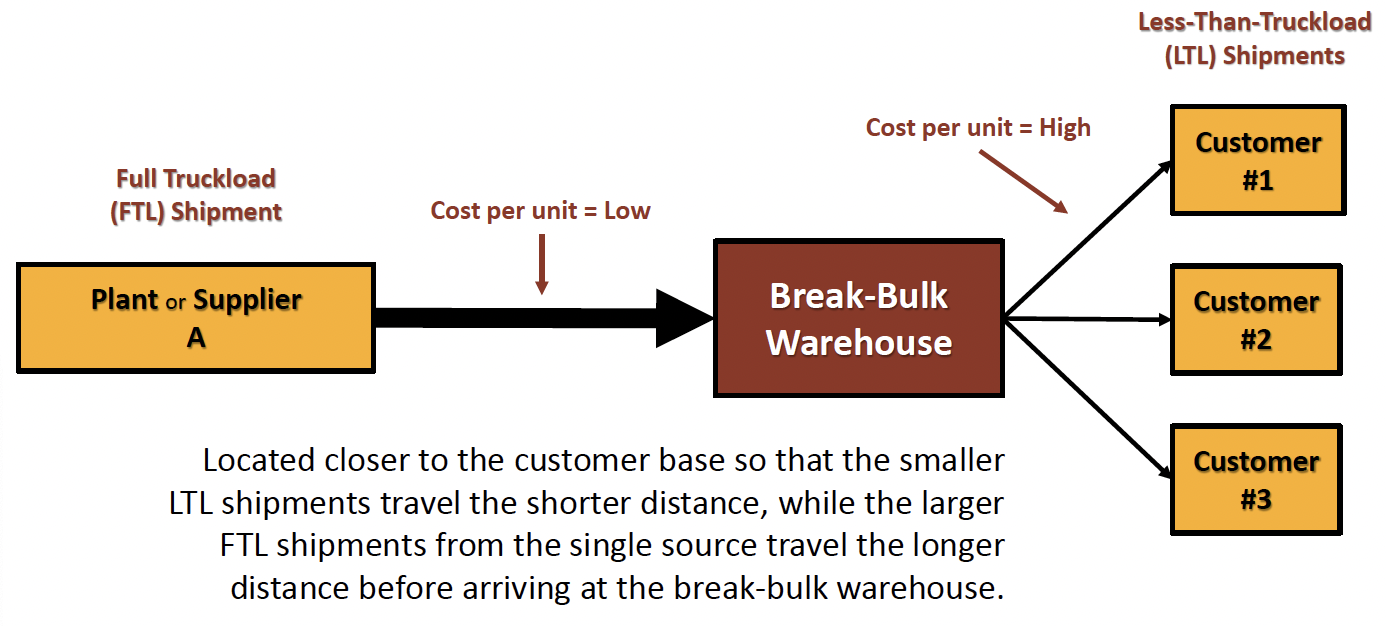

Break-bulk warehouse

Break-bulk warehouse - Warehouse operation that divides full truckloads of items from a single source or manufacturer into smaller, more appropriate quantities for use or further distribution

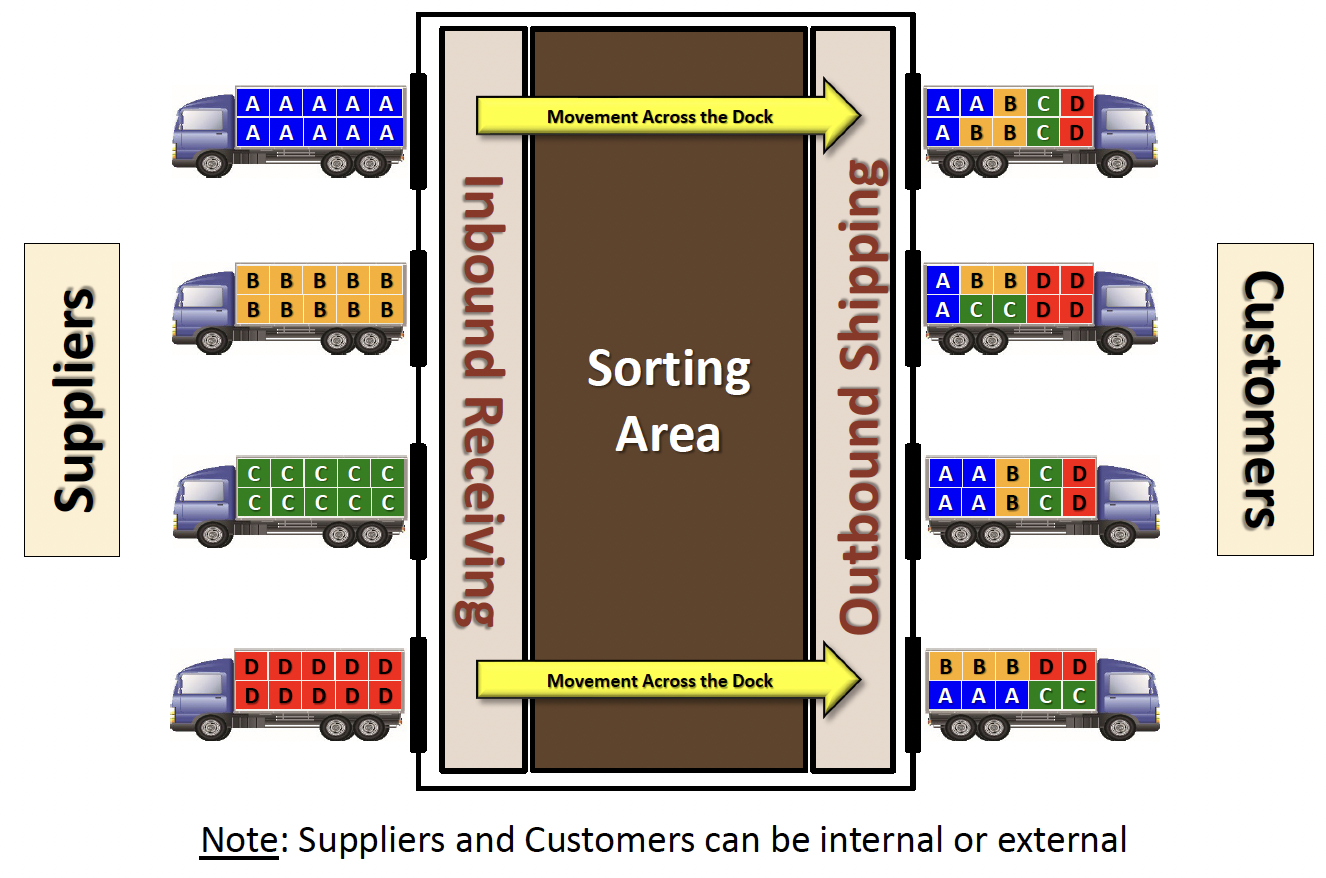

Cross-docking warehouse

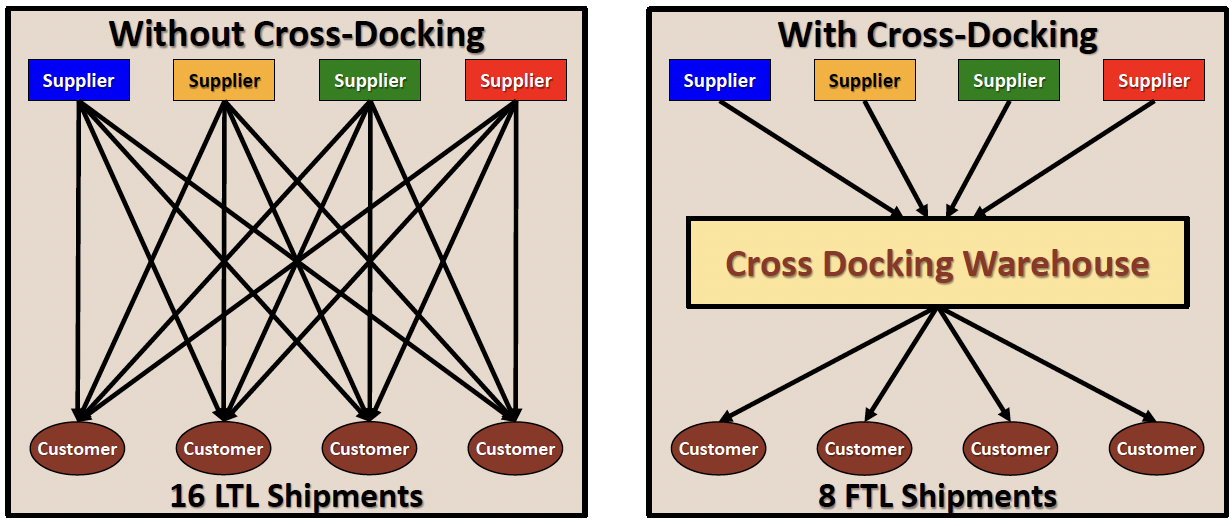

Cross-docking warehouse - The logistics practice of unloading materials from an incoming truck or railcar and loading these materials directly onto outbound trucks or railcars, with little or no storage in between to reduce inventory investment and storage space requirements

Main reasons for implementing cross-docking

Provide a central site for products to be sorted and combined for delivery to multiple destinations in the most productive and fastest method possible

Consolidate: Combine smaller product loads into one method of transport to save on transportation costs.

Break-Bulk: Break down large product loads into smaller loads for transportation for an easier delivery process to the customer

Advantages

Transportation cost savings: 8 FTL Shipments are less expensive per unit than 16 LTL Shipments.

Operational Efficiency: Warehouse operations are more efficient as the material does not have to be stored at the warehouse, moving directly from receiving to shipping.

Inventory Efficiency: As there is no storage at the warehouses, total inventory in the supply chain can be reduced

Warehouse network

Warehouse network - the number of, and the relationship between, the warehouses that a company has in their organizational structure.

fundamental questions to be answered in establishing a warehouse network are:

How many warehouses are needed?

Where should they be located?

Trade-offs that will determine how many warehouses the company needs and where they should be located are:

The level of customer service the company wants to provide

The greater the desired custom service level –the more warehouses the company may need to geographically disperse inventory.

The amount of inventory the company is willing to invest in

The more warehouses the company needs –the greater the amount of inventory the company will need to invest

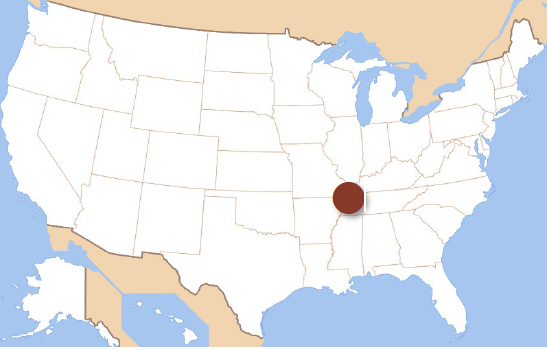

Single warehouse

Pros

Less complicated

Operating costs and inventory will be lower

No duplication of equipment, warehouse staff, and managers

Network will be centralized and the company will have its best people, equipment and inventory systems concentrated in one place.

Warehouse can more actively focus on the needs of its customers

Cons

The single warehouse (i.e., centralized network) may take longer to deliver product to some customers who are remote from the central location

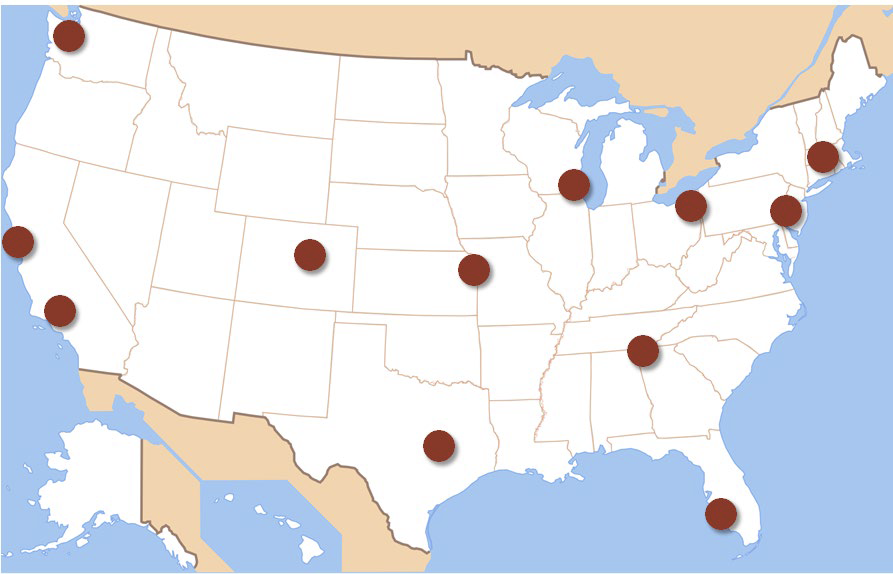

Multiple warehouses

Pros

Potentially faster delivery to customers from a decentralized network that is geographically dispersed throughout the market, assuming adequate inventory in each warehouse

Cons

More complicated

Operating costs and inventory will be higher as each warehouse costs money to staff and operate. Duplication of equipment, warehouse staff, and managers

Network will be decentralized and the company will have to spread its best people, equipment and inventory systems across a larger network

Hybrid approach

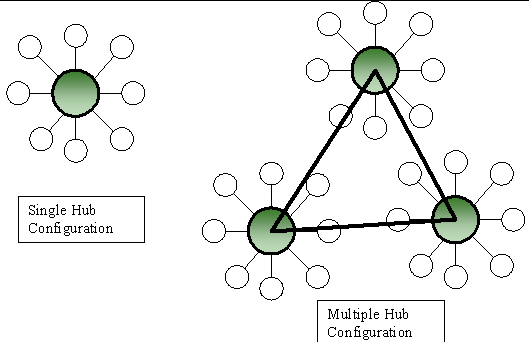

One hybrid network is a “hub-and-spoke” where there is a centralized warehouse (i.e., the “hub”) which holds most of the inventory linked to a series of smaller geographically dispersed warehouses (i.e., the “spokes”) which hold only a small amount of inventory to support their local area in the immediate time frame

The hub warehouse feeds the spoke warehouses with inventory as necessary on a regular basis

Operating costs are lower because the spoke warehouses are smaller than in a purely decentralized model

Inventory is also lower as all of the safety stock is held centrally, which generally means that less total safety stock is required because all of the risk and uncertainty is managed centrally.

Customer service is generally better than in a purely centralized model since some of the inventory is maintained closer to the customer

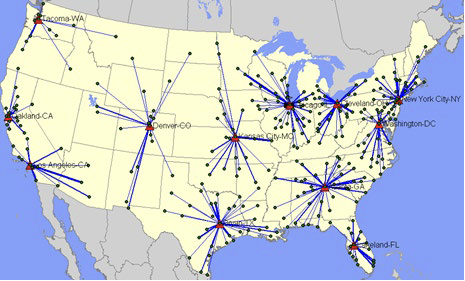

Warehouse network strategy

Whether a company determines that it needs one or multiple warehouses, it will also have to determine which location strategy makes the most sense for its business.

The strategy decision will be different from one business to another, depending on the nature of the business and how many customers and suppliers the company has.

The 3 main warehouse network location strategies are:

Market Positioned Strategy

Product Positioned Strategy

Intermediately Positioned Strategy

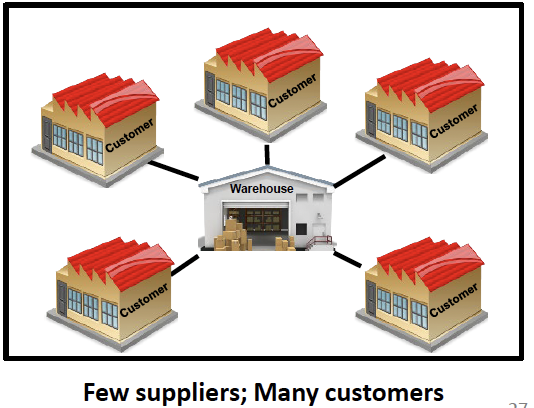

Market positioned strategy

Warehouses are set up close to customers to maximize distribution services and improve delivery.

Companies use this strategy when they have many more customers than suppliers, and the customers are spread out geographically around the market.

If the warehouses are closer to the customers the company can minimize transportation cost

There will likely be FTL shipments coming in from suppliers from greater distances, and LTL shipments going out to customers from shorter distances

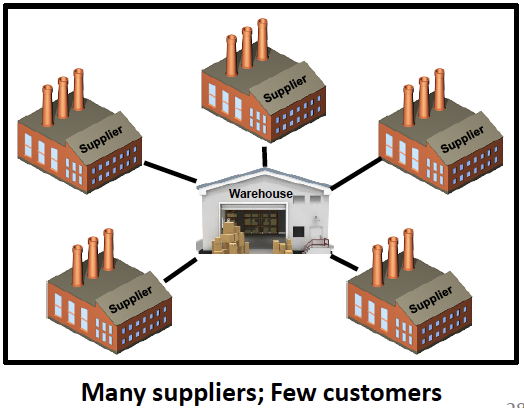

Product positioned strategy

Warehouses are set up close to supply sources to collect goods and consolidate before shipping products out to customers.

This is the reverse of the market positioned strategy.

Companies use this strategy when they have many more suppliers than customers.

If the warehouses are closer to the suppliers the company can minimize transportation cost

There will likely be LTL shipments coming in from suppliers from shorter distances, and consolidated FTL shipments going out to customers from longer distances

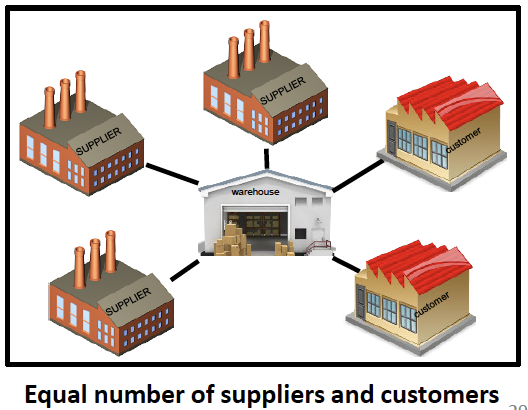

Intermediately positioned strategy

Warehouses are set up somewhere midway between the supply sources and the customers to try to balance costs, inventory and customer service.

This strategy is used when distribution requirements are high and product comes from various supply locations.

A warehouse network optimization study may be needed to determine the optimal number and location of warehouse in this strategy

Third party logistics (3PL)

Third party logistics (3PL) company - an outsourced provider that manages most or all of an organization’s logistics requirements for a fee

Typically generate a 10-20% savings in logistics costs

Favored by small businesses

Used significantly for international logistics

Typical 3PL services

Inbound Transportation

Outbound Transportation

Warehousing

Pick and Pack

Freight Forwarding

Customs Brokerage

Customs Clearance

Order Taking

Billing and Invoicing

Inventory Auditing

Freight Bill Auditing and Payment

Advantages of 3PL

Cost: eliminate the need for a company to invest in warehouse space, technology, and staff to execute the logistics process

Logistics expertise: knowledgeable of industry best practices and latest technological developments

Efficiency: 3PLs can leverage relationships and volume discounts → lower overhead and fastest possible service

Disadvantages of 3PL

Control: company lacks direct control over logistics

Dependency: outsourcing logistics creates dependence on 3PL

Pricing: company is locked into pricing model specified in contract

Fourth party logistics (4PL)

Fourth party logistics (4PL) - an interface between the client company and multiple logistics service providers

A company will select a lead logistics partner (i.e., 4PL) that is then charged with managing the activities of all the other 3PLs being used by the company

Ideally, all aspects of the client company’s supply chain handled by 3PLs would be managed by the 4PL organization

Transportation company classification

Contract carriers - person or company who transports freight under contract to one or a limited number of shippers

Private carriers - person or company that transports its own cargo as part of a business that produces, uses, sells, or buys the cargo that is being hauled

Common carriers - person or company who transports freight for a fee that can be hired by anyone to transport goods

Exempt carriers - person or company specializing in services or transporting commodities exempt from regulation by the Interstate Commerce Act

Transportation

Transportation - the function of planning, scheduling, and controlling activities related to the mode, carrier, and movement of inventories into and out of an organization

Objectives

To maximize the value to the company through price negotiation

To make sure service is provided effectively

To satisfy customers’ needs

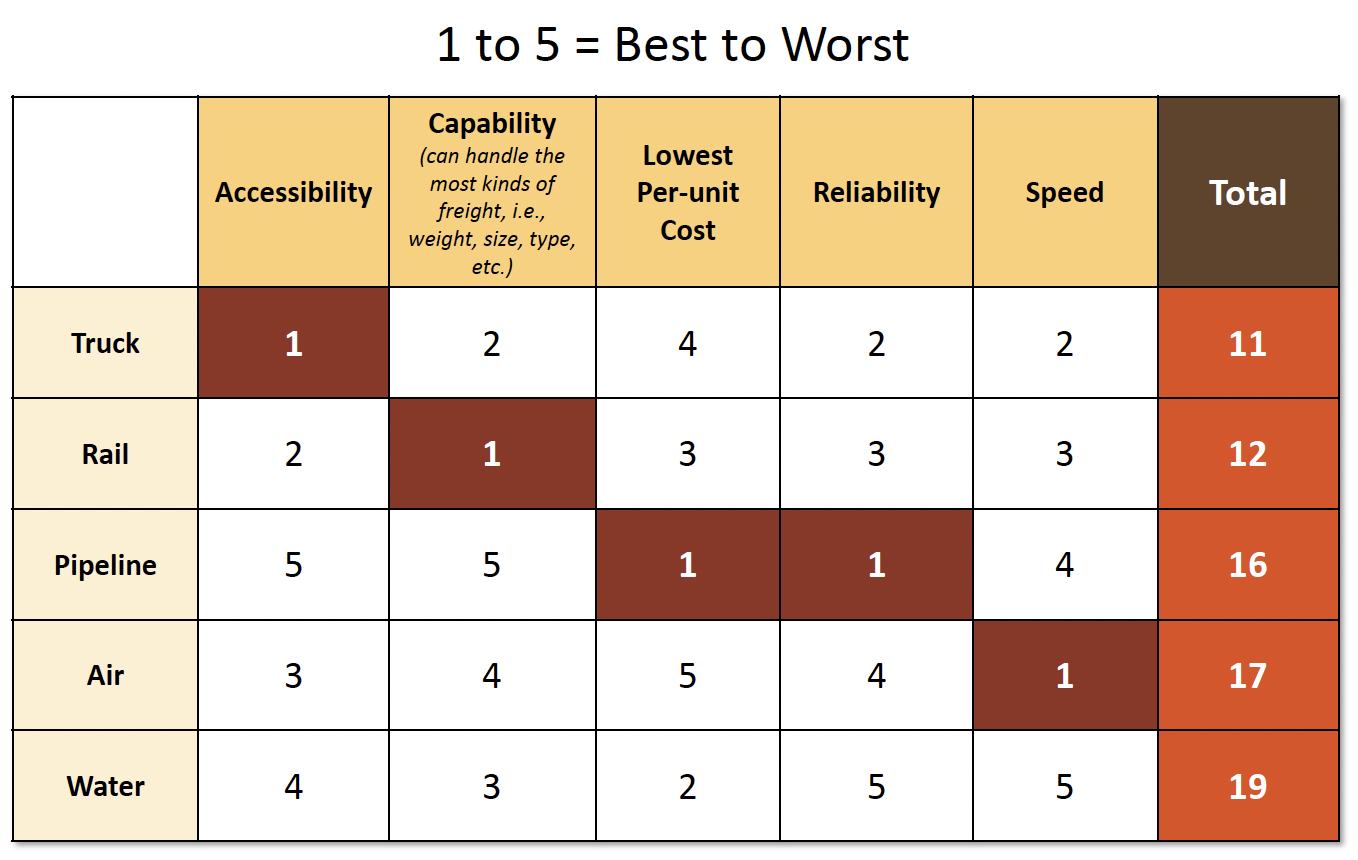

Modes of transportation

Mode - the way in which goods are transported

Carrier - the company that transports the goods

Truck

Most flexible mode of transportation

Carries >80% of U.S. freight

Because of interaction with other transportation modes to and from ports and warehouses

Carries nearly anything from packaged household goods to building materials to liquid petroleum, etc.

Competes with Rail and Air for short-to-medium hauls

Short haul - 0-200 miles from driver’s home terminal

Long haul - over 200 miles from driver’s home terminal

Impacted by truck driver shortage and hour-of-service rules

General freight carriers - a trucking company which handles a wide variety of commodities in standard trailers. Freight is generally palletized

Can be LTL or FTL carriers

Carry the majority of goods shipped

Does not require the use of specialized equipment

Specialized carriers - a trucking company that handles the movement of cargo that requires specialized equipment for transportation because of shipment’s size, weight, and shape

Transport commodities like liquids, petroleum, household goods, building materials, and other specialized items

Less-than-truckload (LTL) - freight does not require entire truck space

Advantages:

Can be cost effective

More available carrier options

Ideal for small businesses

Disadvantages:

Increased risk of theft/damage

Increased shipping times and delays

Full-truckload (FTL) - the transport of goods that fill up a full truck

Advantages:

Best way to transport large shipments

Ideal for high risk or delicate freight shipments

Considerably faster than LTL

Disadvantages:

Costs more than LTL

Rail

Accounts for approximately 9% of total U.S. freight spend

Competes for transportation when the distance is long and shipments are heavy or bulky

Shipments involve building materials, construction equipment, coal, gravel, sand, lumber, etc.

Aging infrastructure and equipment are an issue

Rail is slow and inflexible but has the most capability

Paired with trucks for door-to-door delivery

Rail carriers have begun purchasing motor carriers and can now offer point-to-point pickup and delivery service

Pipeline

Accounts for ~2% of total U.S. freight spend

Most reliable form of transportation

Lowest per unit cost for transportation

Limited variety of commodities

Materials are transported in liquid or gaseous state

Little maintenance needed once pipeline is running

Air

Accounts for ~5% of total U.S. freight spend

Generally fastest mode of transportation

Most expensive

Cannot carry extremely heavy or bulky cargo

Ideally items with high cost to weight ratio

Shipments involve very light, high-value goods that need to travel long distances quickly

Ex.: jewelry, fine wines, pharmaceuticals, racehorses

Half of the goods transported by air are carried by freight-only airlines. Other half in passenger planes with luggage

Paired with trucks for door-to-door delivery

Water

Accounts for ~5% of total U.S. freight spend

Includes waterways, coastal and intercoastal, and deep-sea cargo shipments

Inexpensive

Very slow and inflexible

Primarily used for heavy, bulky, low value materials like coal, grain, sand, and petroleum

However, because transport by water is so cheap, almost any item may be shipped by water including automobiles, produce, containerized cargo, etc.

Competes with rail and pipeline for some cargo shipments

Paired with trucks for door-to-door delivery

Intermodal transportation

Intermodal transportation - the use of multiple modes of transportation to execute a single transport shipment

Growing substantially because it is fairly cost-efficient and cost-effective

Most common forms:

Rail and motor carriers (i.e., trucks)

Offer point-to-point pickup and delivery service known as trailer-on-flatcar (TOFC)

Rail and water carriers

Offer point-to-point pickup and delivery service known as container-on-flatcar (COFC)

Roll-on/roll-off ships

Specifically designed to allow trucks to be driven directly on and off the ship without the use of cranes

Provides flexibility and speed

Freight

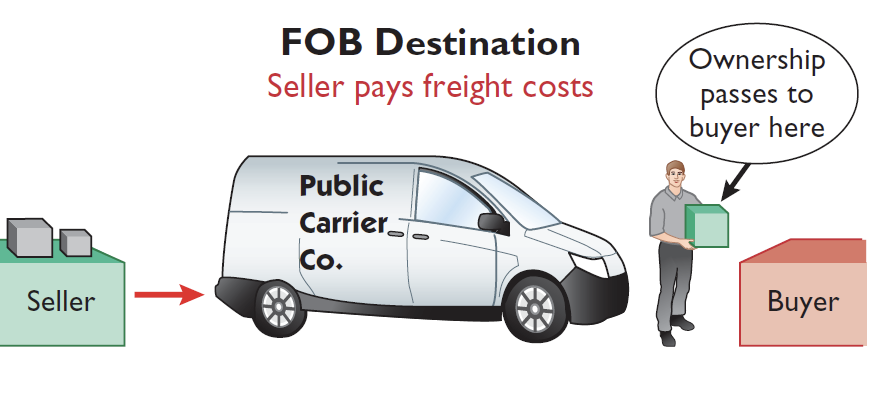

Freight: terms of sale - delivery and payment terms agreed upon between buyer and seller

Free on Board (FOB) origin - seller places goods FOB with carrier at the seller’s location and buyer pays freight costs

Ownership of goods passes to buyer when public carrier accepts goods from seller

Buyer assumes risk for in-transit loss or damage

Free on Board (FOB) destination - seller places goods FOB to buyer’s place of business and seller pays freight costs

Ownership of goods remains with seller until goods reach buyer

Seller assumes risk for in-transit loss or damage

Other transportation intermediaries

Freight forwarder - consolidates LTL shipments into FTL shipments

Load/transportation broker - bring shippers and carriers together

Shippers’ association - nonprofit cooperatives which arrange for members’ shipping

Intermodal marketing company - purchase blocks of rail capacity and sell it to shippers

Reverse logistics (aka returns management)

Reverse logistics - process of moving a product from the point of customer receipt back to the point of origin to recapture value or esure proper disposal

Backward flow of goods from customers in the supply chain

All about damage control and making the process as customer-friendly as possible

5 R’s of reverse logistics

Returns - Customers return products because an item may be defective, damaged, seasonal, fail to meet expectations, be excess inventory, etc

Recalls - more complex than basic returns because they typically involve a product defect or potential hazard and may be subject to government regulations, liability concerns or reporting requirements

Repairs - Not all products that are returned are disposed. Manufacturers may identify the failure and repair, refurbish or remanufacture the product to like-new condition and return it to stock, or harvest various components for reuse

Repackaging - 95% of returned products are because customers are dissatisfied with them not because they are defective. These products are typically repackaged and returned to inventory for restock or resale.

Recycling - When products reach the ends of their useful lives and must be scrapped, companies must find safe, cost-effective and environmentally friendly ways to dispose of them. Companies can reduce costs and minimize waste

Chapter 10: Global Logistics & International Trade - 11%

Offshore factory

Offshore factory - a factory set up for manufacturing or assembly in a country where labor and/or raw materials are less expensive for eventual import back into manufacturer’s home country

Source factory

Source factory - Manufactures products at low cost but with skilled workers and significant managerial resources

Server factory

Server factory - set up to take advantage of government incentives

Contributor factory

Contributor factory - focused on product development and engineering for products that they manufacture

Outpost factory

Outpost factory - factory set up in an area with an abundance of advanced suppliers, competitors, research facilities, etc.

Lead factory

Lead factory - Source of product and process innovation and competitive advantage across the entire organization (world-class); “Go-to” factory

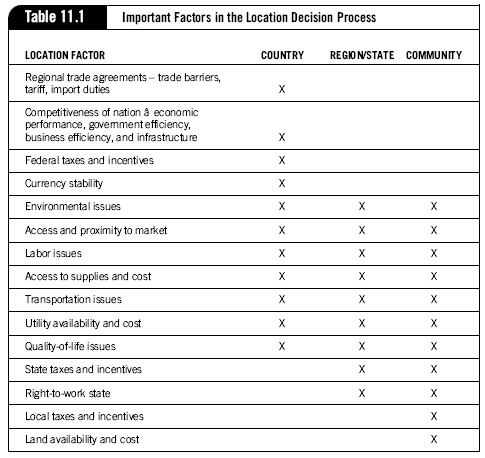

Global location factors

Competitiveness

Taxes and incentives

Currency stability

Access and proximity to markets

Labor issues

Right to work laws

Access to suppliers and cost

Utility availability and cost

Environmental issues

Land availability and cost

Quality of life issues

Business clusters

Trade agreements

Used to compare and contrast one potential location against another

Competitiveness

12 pillars of competitiveness

Institutions

What’s nearby

Infrastructure

Macroeconomic stability

Health and primary education

Higher education and training

Nearby universities, education system of the country

Goods market efficiency

Labor market efficiency

Financial market sophistication

Technological readiness

Market size

Business sophistication

Innovation

Taxes and incentives

Several levels of government must be considered when evaluating potential locations

Tariffs - federal taxes that are designed to protect local businesses

Countries with high tariffs discourage importing goods into the country and encourage multinational corporations to produce locally

Currency stability

Impacts business costs and consequently location decisions

Years back, Brazil had 1000% annual inflation rate. Not so easy to set prices in that currency environment

Access and proximity to markets

The trend in manufacturing is to be within delivery proximity of your customers.

Logistics timelines and costs are the concerns, so that reinforces a clustering effect of suppliers and producers to places that offer lower cost labor and lower real estate prices.

In the service industry, proximity to customers is even more critical.

You can’t service a washing machine if your technician is 3000 miles away

Labor issues

Labor availability, productivity, and skills

Unemployment/underemployment rates

Wage rates; turnover rates; labor force competitors

Right-to-work laws

28 states have laws protecting the right of employees to decide whether or not to join or support a union

Access to suppliers and cost

Supplier proximity influences the delivery of materials and the effectiveness of the supply chain

Utility availability and cost

Supply of electricity has not always kept pace with the high speed of development

China (2006) made several factories shut down for 1 day/week

In heavy industries the availability and cost of energy are critical considerations

Telecommunication costs have dropped dramatically. Many organizations now have back office operations and call centers internationally to serve the U.S. market

Environmental issues

Global warming, air pollution, acid rain are debated as being the price of industrialization

Trade liberalization creates the need for environmental cooperation

Land availability and costs

As land and construction costs in big cities continue to escalate, the trend is to locate in the suburbs and rural areas

Quality-of-life issues

You need people to work at these locations → consider quality-of-life issues in terms of maturity, sophistication, robustness, etc. and compare/evaluate:

Education

Economy

Natural Environment

Social Environment

Culture

Healthcare

Government / Politics

Mobility

Public Safety

Recreation

Business clusters

Geographic concentrations of interconnected companies and institutions

Research parks and special economic / industrial zones serve as magnets for business

Reasons for success:

Innovation and competition can be geographically concentrated

Close cooperation, coordination, and trust among clustered companies

Fierce competition among rival companies

Companies recruit from local skilled workers

Regional trade agreements

European Union (EU): [1950] following WWII, consists of

27(Brexit) 26 members countries in EuropeNorth American Free Trade Agreement (NAFTA): [1994] Removed most barriers to trade and investment among U.S., Canada and Mexico.

Southern Common Market (MERCOSUR): [1991] among Argentina, Brazil, Paraguay, and Uruguay

Association of Southeast Asian Nations (ASEAN): [1967] among 10 member countries in in SE Asia

Common Market of Eastern and Southern Africa (COMESA) [1993] among 19 member countries in Eastern and Southern Africa

World Trade Organization

World Trade Organization (WTO) - deals with the global rules of trade between nations

Main goal: ensure trade flows smoothly, predictably, and as freely as possible

WTO functions

Administering agreements

Forum for trade negotiations

Trade disputes

Monitor trade policies

Aid for developing countries

International organizations

Global location decision factors

Location evaluation techniques

Weighted-factor rating model

Compares the attractiveness of several locations along a number of quantitative and qualitative dimensions

Steps:

Identify the factors

Assign weights to each factor. The weights sum to 1.

Determine a score for each factor.

Multiply the factor score by the weight, then sum the weighted scores

The location with the highest total weighted score is the recommended location

U.S. Department of Homeland Security (DHS)

Department of Homeland Security (DHS) - government agency whose mission is to:

Prevent terrorist attacks within U.S.

Reduce America’s vulnerability to terrorism

Minimize damage from potential attacks and natural disasters

March 1, 2003: DHS assumed responsibility for securing our nation’s borders and transportation systems which straddle 350+ official ports of entry and connects our homeland to the rest of the world

First priority: prevent entry of terrorists and instruments of terrorism while ensuring efficient flow of lawful traffic and commerce

U.S. Customs and Border Protection (CBP)

Customs and Border Protection (CBP) - controls import process

Originally established in 1978

Became part of DHS in 2003

The “gateway agency” for more than 20 other government agencies each of which has some control over various aspects of international trade

Mission: to safeguard America’s borders thereby protecting the public from dangerous people and materials while enhancing nation’s global economic competitiveness by enabling legitimate trade and travel

CBP works to secure and facilitate imports arriving in the U.S., accommodating the increasing volume and complexities of international trade

“Pushing borders back”

CBP protects U.S. through active inspections at ports of entry.

CBP has a strong base of industry partnerships and technology to safeguard the American public and promote legitimate international commerce

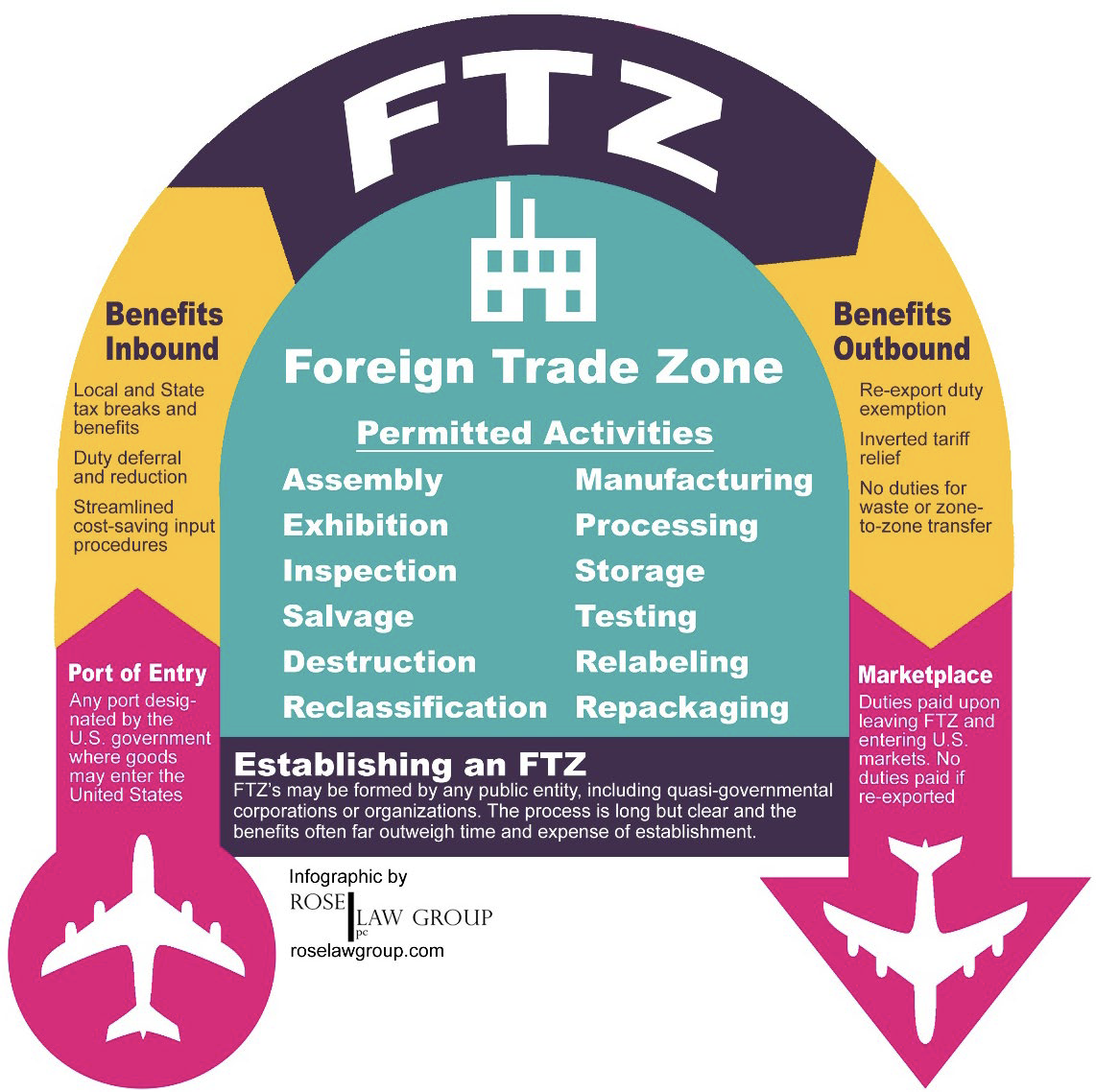

Foreign trade zones (FTZs)

Foreign trade zones - physical areas inside the U.S. supervised by U.S. Customs and Border Protection that are considered outside of the U.S. territory

Usually located at or near a port of entry

Foreign and domestic merchandise may be moved into FTZs for operations not otherwise prohibited by law, including these Permitted Activities:

Port of entry - any port designated by U.S. government where goods may enter U.S.

Benefits inbound: local and state tax breaks and benefits; duty deferral and reduction; streamlined cost-saving input procedures

Benefits outbound: re-export duty exemption; inverted tariff relief; no duties for waste or zone-to-zone transfer

Marketplace - duties paid upon leaving FTZ and entering U.S. markets. No duties paid in re-exported

While in the FTZ, merchandise is not subject to U.S. duty or excise tax

U.S. duty and excise tax, if applicable, are only payable when the material is moved outside the FTZ for consumption

Permitted activities: assembly, exhibition, inspection, salvage, destruction, reclassification, manufacturing, processing, storage, testing, relabeling, repackaging

Foreign-trade zone sites are subject to the laws and regulations of the United States as well as those of the states and communities in which they are located.

There is no limit on the time material may remain in the zone.

Internationally, similar areas are called Free Trade Zones

Deemed exports

Deemed export - the release of technology or source code that is subject to the Export Administration Regulations to a foreign national (i.e., non-US citizen) located in the U.S.

An intentional or unintentional export of controlled technology can easily occur within the walls of your company, even if located within the borders of the United States

The release can be visual, oral, through on the job training, or via systems access, etc.

“Technology” - the specific information necessary for the development, production or use of a commodity

Usually, technology is even more strictly controlled than a commodity

The proper controls are needed to ensure that any such export occurs legally (i.e., with the proper licenses and approvals) and does not expose you or your company to penalties

Examples

Allowing a foreign national to view blueprints of a U.S. missile guidance system

Allowing foreign national to download U.S. encryption software from a laptop

Sending a foreign national U.S. software using email

Giving a foreign national access to a portal containing restricted information

Conducting a facility tour for a foreign national

Global logistics intermediaries

Customs brokers - move global shipments through customs and handle documentation

International freight forwarders - move goods to and from foreign destination

Trading companies - put buyers and sellers from different countries together and handle export/import arrangements, documentation, and transportation

Non-vessel-operating common carriers (NVOCC) - operate like freight forwarders but only use scheduled ocean liners

Chapter 11: Customer Relationship Management (CRM) - 7%

Customer relationship management

Customer relationship management (CRM) - the transformation of the people, process, and technology required to become a customer-centric organization

Customer first philosophy

Involves acquiring, retaining and partnering with selective customers to create superior value for both the company and the customer.

It provides a means and a method to enhance the experience of individual customers so that they will remain customers for life

CRM is about building and maintaining profitable long-term customer relationships beyond the one-off buy and sell transaction

By:

Focusing on customer requirements

Delivering products and services in a manner resulting in high levels of customer satisfaction

How:

Communicating with customers

Understandingtheir behavior and their requirements

Building a system to satisfy those requirements

Focus on strategically significant customers

Not all markets and customers are equally important

Building relationships with customers that provide little value can be counterproductive

Relationships should be built with strategically significant customers that are likely to provide the most value for the effort

Strategically significant customers:

Customers with high life-time value

i.e., customers that will constantly buy the product(s) or use the service(s) in the long-term

Customers who serve as role models or benchmarks for other customers

Customers who inspire change in the supplier and/or the supply chain

Comes from relationship building and trust

CRM is not for every customer

Some customers don’t want to be committed to every brand and/or relationship

Key tools and components of CRM

Personalizing customer communications

Understanding customer behaviors and preferences, allows a firm to customize communications aimed as specific groups of customers and is likely to result in greater levels of sales

When a company communicates with their customers they need to use the customer’s “language” and communicate with them in a meaningful way

Communication that is personalized sends a message to the customer that the company cares about them

It is a powerful way to differentiate the company from its competitors and it helps to build customer loyalty

Clickstream - tracking how a customer navigates a website can help tailor a website’s images, ads or discounts based on past usage of the site

Cross-selling and up-selling

Cross-selling - occurs when a company sells an additional related or complementary product or service to an existing customer after the initial purchase

Ex.: "Would you like fries with that?"

Ex.: If you're buying an item on Amazon.com, you may be shown other similar items to the one you are looking at, or companion products to the item that you are considering

Up-selling - involves persuading a customer to buy a more expensive item or upgrade a product or service to make the sale more profitable. It also involves selling the customer extra features or add-ons to the product they are already buying or considering

Ex.: “Would you like to super-size your order?”

Relationship marketing or permission marketing

Relationship/permission marketing - an approach to selling products and services in which a customer explicitly agrees in advance to receive marketing information. Customers self-select the type and time of communication they want

Ex.: An “opt-in” e-mail, where a potential customer signs up in advance for information about certain products or services. The customer is giving permission to the company to provide them with marketing and sales information

Permission marketing is about building an ongoing relationship of increasing depth with customers

Permission marketing does not typically create immediate sales, but rather grabs a customer's attention and preserves a business relationship

Customer defection analysis

Customer defection analysis - the process of analyzing the customers who have stopped buying to determine why

Finding a new customer costs 5-10x as much as keeping an existing customer

Churn reduction

Churn - the process of customers changing their buying preferences because they find better or cheaper products and services elsewhere

Churn reduction - all of the efforts companies develop to stop losing customers to the competition

Customer Defection Analysis and Churn Reduction go hand-in-hand to determine why customers leave and finding ways to retain them

5% improvement in customer retention can result in a 75% increase in profits

Customer lifetime value (CLV)

Customer lifetime value (CLV) - a prediction of the net profit attributed to the entire future relationship with a particular customer

Some customers are worth a lot more than others, and identifying your key or top tier customers can be extremely valuable to your business.

CLV is an important metric for determining how much money a company is willing to spend on acquiring new customers and how much repeat business a company can expect from particular customers

Chapter 12: SCM in the Service Industry - 37%

Overview of Service Operations

SCM in the Service Industry

How does supply chain management in the service industry differ from supply chain management in manufacturing?

The tangibility of the end product: Services are generally not tangible

The involvement of the customer in the service process: Customers are much more directly involved in the service industry

The assessment of quality: Quality is assessed differently in the service industry

The labor content: There is a much higher ratio of labor to materials in the service industry

The facility location considerations: Services are largely provided very near where customers are located and heavily impacted by location decisions.

Types of services

Pure services - offer very few or no tangible products to customers

Ex.: consulting, storage facilities, training/education, etc.

End product services - offer tangible components along with the service component

Ex.: restaurants; food along with the dining service)

State utility services - directly involve things owned by the customer

Ex.: car repair, dry cleaning, haircut, and healthcare

Differences between goods and services

Services cannot be inventoried (in most cases). Typically, services are produced and consumed simultaneously.

Services are often unique to the customer

Ex.: insurance policies, legal services, tax preparation, etc.

Services have high customer interaction

Services are decentralized. Due to the inability to inventory or transport most services, they must be located near to the customer base

Managing the service supply chain

Service strategies

Cost leadership: lowest cost service provider

Requires large capital investment in the state-of-the-art equipment and significant efforts to control and reduce costs

Ex.: auto diagnostics software, route planning to reduce windshield time, UPS optimization, etc.

Differentiation: unique service created based on customer input and feedback

Ex.: Sunday car servicing at Hyundai, Ford, etc. Being different from another local dealer. This may be helpful in selling a car to someone who can’t take off work on a Monday-thru-Friday when their car needs repair

Focus: serve a narrow niche better than other firms

Ex.: grocery shopping for you, mechanic specializing in Volvo or Porsche repair, custom stereo in your house or car

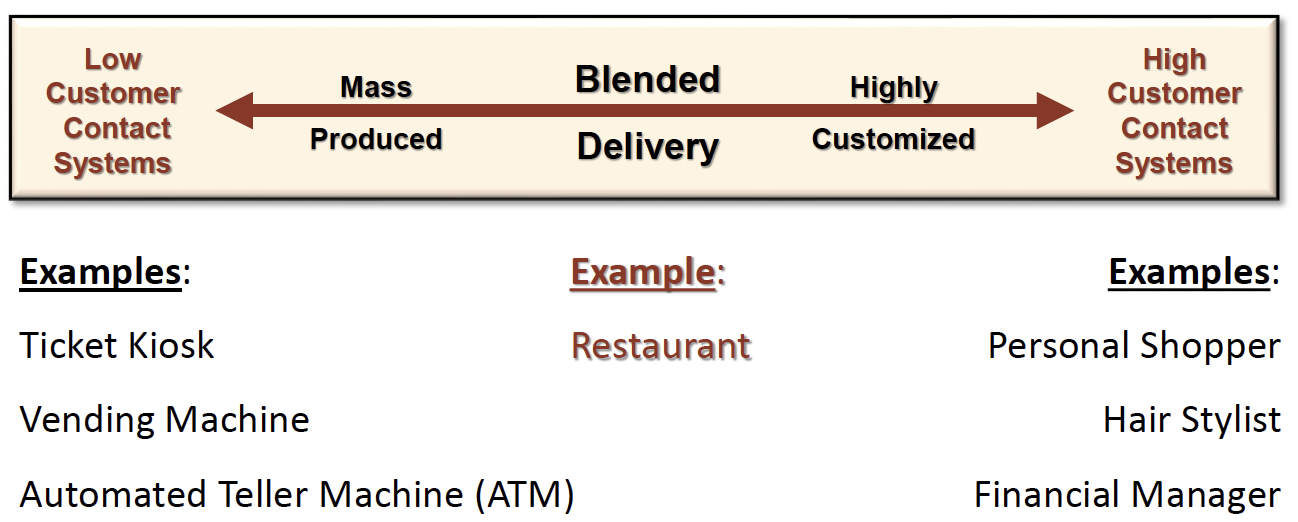

Service delivery system

Delivery of service - a continuum with mass produced, low-customer contact systems at one end, and highly customized, high-customer-contact systems at the other

Blended delivery system - involve both high and low customer contact systems

Ex.: restaurant: front of house staff tend to be customer-centric while back of house staff generally do not have contact with customers

Service delivery systems may be designed to keep these separate in order to use various and different management techniques to maximize performance in each area

Bundle of service attributes

Bundling services can deliver more than expected and enhance customer satisfaction

Explicit services - availability and access to the service, consistency of service performance, comprehensiveness of the service, and training of service personnel

Ex.: safe deposit boxes, loans, etc.

Implicit services - attitude of the servers, atmosphere, waiting time, status, privacy, security, and convenience

SUPPORTED BY:

Facilities and Equipment - location, layout, architectural appropriateness, equipment, decoration

Ex.: drive-up tellers, ATM’s

Facilitating Goods - tangible elements that are used or consumed by the customer or the service provider along with the service provided

Ex.: deposit forms, statements

Service response logistics

The primary concern of service response logistics is the management and coordination of the organization’s service activities

The four primary activities of Service Response Logistics are managing:

Service Capacity

Waiting Times

Distribution Channels

Service Quality

Since services cannot be inventoried and customer demand must be met, Demand Management Tactics are also important

1. Service capacity

Service capacity - expressed as the number of customers that the service provider can service at any one time

the number of customers per day, per shift, per month, or per year, that the company’s service system is designed to serve

Regardless of the specific breakdown, it's The planned capacity for the service environment

Service providers are 100% reliant on the customer to create the flow of demand, which has a direct impact on their ability to fully utilize capacity

Challenges:

Customer arrivals fluctuate and service demands vary.

Customers are participants in the service and the level of congestion impacts on perceived quality.

Idle capacity is a reality for services

Inability to control demand results in capacity measured in terms of inputs

Ex.: number of hotel rooms available rather than the number of guest nights

Examples

Airline capacity: number of seats vs. booked passengers

Restaurant capacity: number of tables

How many servers will I need?

Maître d’s / Hostesses?

Chefs / Kitchen staff?

“Bus-boys” / Dish-washers?

Hotel capacity: number of rooms

How many people will I need to :

Check-in / Check-out the customers

Tend the bar

Clean the rooms

Handle the luggage

Provide room service

Service capacity utilization formula

Capacity utilization = Actual customers served per period / Capacity

Managing Service Capacity

Level demand strategy - Capacity remains constant regardless of demand. When demand exceeds capacity, queue management tactics deal with excess customers

One line instead of many lines at a Bank or at McDonald’s so its 1st come 1st serve

Numbers at the deli in the grocery store. Note: This technique does not work well in a Hospital Emergency Room

Chase demand strategy - capacity varies with demand → you can handle fluctuations but must take appropriate actions prior. Need to have options

Open up additional line(s)

Call in additional off-shift workers to meet increased demand

Demand exceeds capacity

If the demand exceeds capacity, and the provider does not currently have the capacity to serve all of the customers, there are three basic alternatives:

Turn customers away and not service them, i.e., lose business.

Make them wait until service is available for them

Increase service capacity: the number of service personnel and the associated infrastructure to provide the service

Hiring, training, supervising, and equipping personnel is costly

~75% of operating costs

Situation makes forecasting service demand critical, particularly because services cannot be inventoried or carried out in advance

To minimize the cost of hiring and laying off employees, the following strategies deal with periods of high demand

Using cross-trained employees so that they can help on the task that is busy at the moment. Flow the people to the work

Using part-time employees (e.g., during the holiday season)

Using customers, i.e., “hidden employees” (e.g., self check out)

Using technology (e.g., Scanning documents in insurance industry for use in multiple departments as necessary)

Using employee scheduling policies (e.g., nurses have to work alternating holidays)

Capacity exceeds demand

If capacity exceeds demand, instead of disposing of excess capacity (e.g., laying off personnel), find other uses for the available capacity

Do other jobs when it’s not busy

Ex.: in a restaurant you might have workers clean the bathrooms, prep for the dinner rush, etc.

Do training or cross training

Use demand management techniques to shift demand from peak demand periods into non-peak periods by offering incentives like discounts and special sales

Ex.: early bird specials, 20% off from 9am to noon, etc.

Service capacity

Long-range - capacity can be used as a preemptive strike where the market is too small for two competitors to co-exist

Ex.: first to build a luxury hotel in a mid-sized city may capture all the business

A strategy of building ahead of demand is often taken to avoid losing customers

Short-range - the lack of short-term capacity planning can generate customers for the competition

Ex.: if restaurant staffing is inadequate to handle the volume of customers arriving at the restaurant, customer will likely go elsewhere

Balance - capacity decisions must be balanced against the costs of lost sales if capacity is inadequate… or against operating losses if demand does not reach expectations

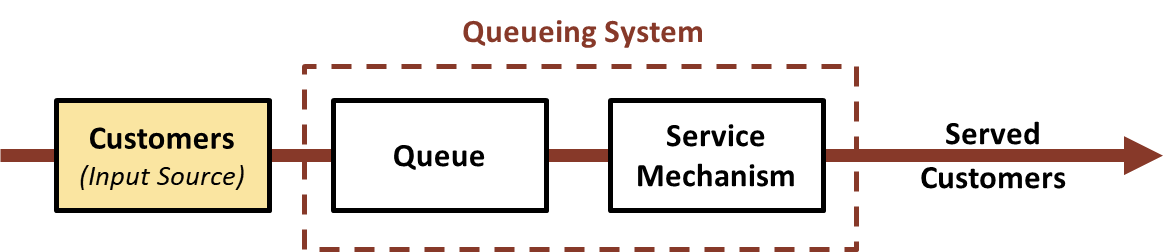

Queuing systems

Queue management system - used to help control the flow and prioritization of people expecting to receive a service

Queues can be utilized for almost any situation where large numbers of people are gathering or waiting in line to purchase tickets, enter a facility, etc.

Queues are common in airports amusement parks, and retail

length of time customers are willing to wait for service before leaving/lowering their perception of the quality of the service company is directly related to the effectiveness of the queueing system being used

Types of queues

Structured queues - queues are set in a fixed position such as a supermarket checkout line, airport or bank. In some cases queue management systems can be structure with numbers such as “take-a-ticket number” allowing a person to walk around and wait for their number to be called

Unstructured queues - when people form queues somewhat informally in various directions and locations. These types of queues are seen in retail stores, at an airport waiting for a taxi, people waiting for an ATM machine, etc.

Mobile queues - queues formed virtually with technology. Customers can use technology such as a smartphone to place their name in a real-time electronic queue such as at a restaurant. This type of queuing has provided a great deal of flexibility and allows for reduced stress level on the part of the customer

Queuing system input

Customers are the demand source for services and their arrival triggers the start of the service experience.

Customers generally appear in predictable arrival patterns

Ex.: dinner rush at a restaurant

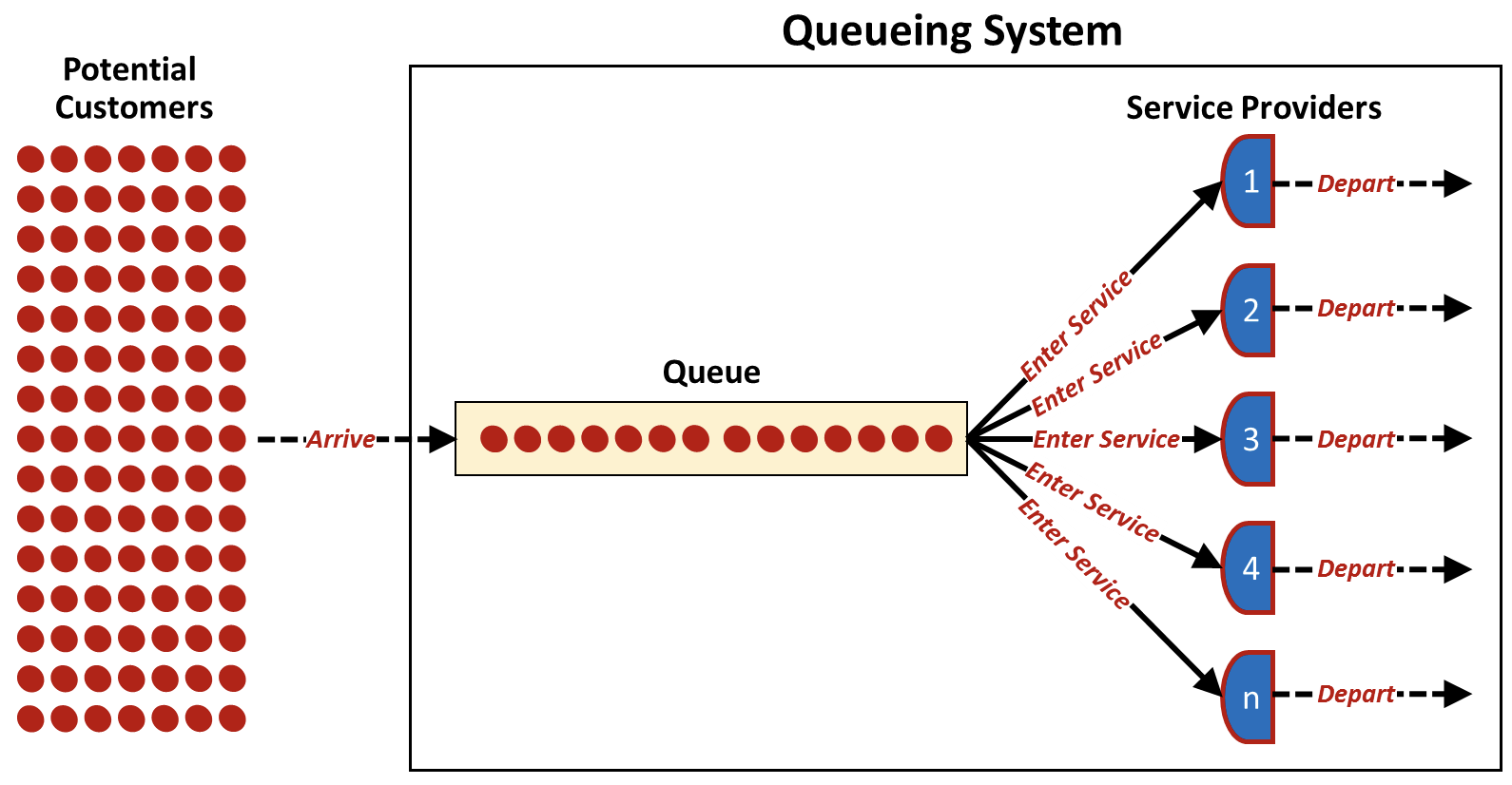

Queuing system

Queuing system assumptions

Most queuing models assume that customers enter the queue, and stay in the queue until served. That may not be true:

Balking - when a customer refuses to join the queue

Reneging - when customers decide to leave the queue

Queuing models assume there is an infinite length of a queue

Queuing system characteristics

Queue discipline - describes the order in which customers are served

Queuing can be comprised of single or multiple lines

Queue lines can be serviced by either a single server or multiple servers. Multiple servers can also act in series or in parallel

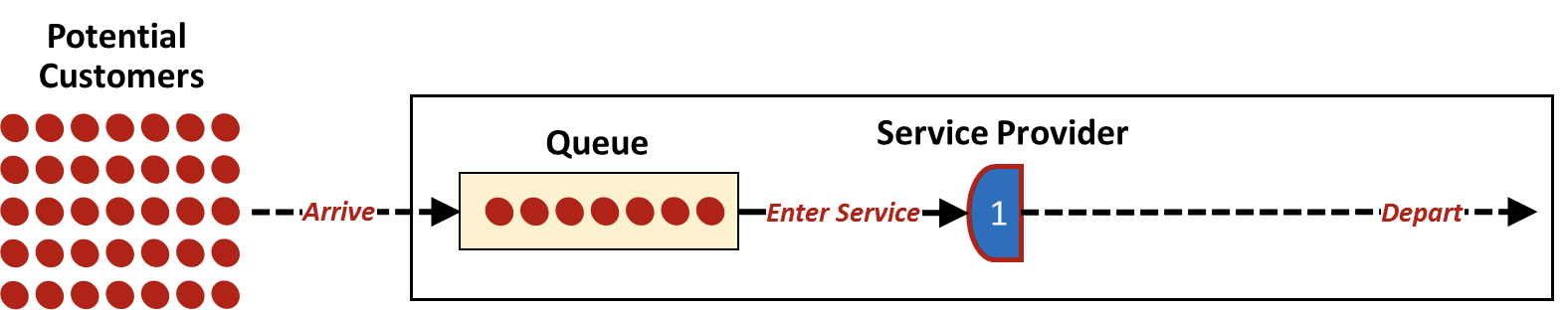

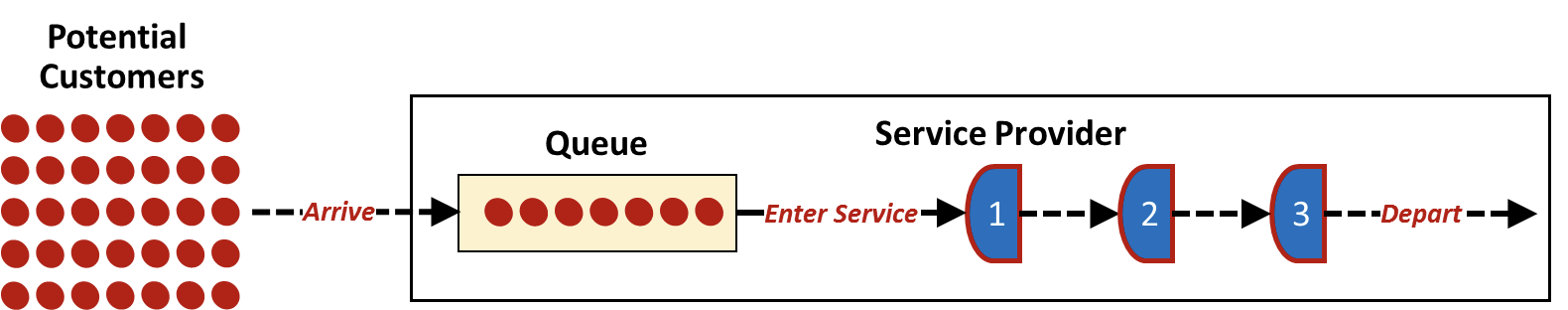

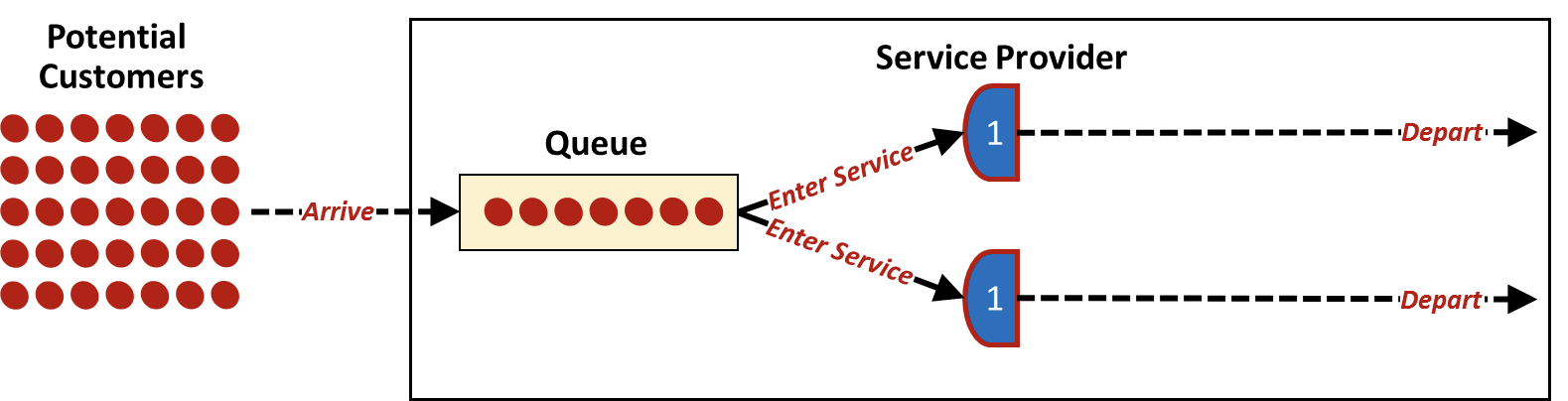

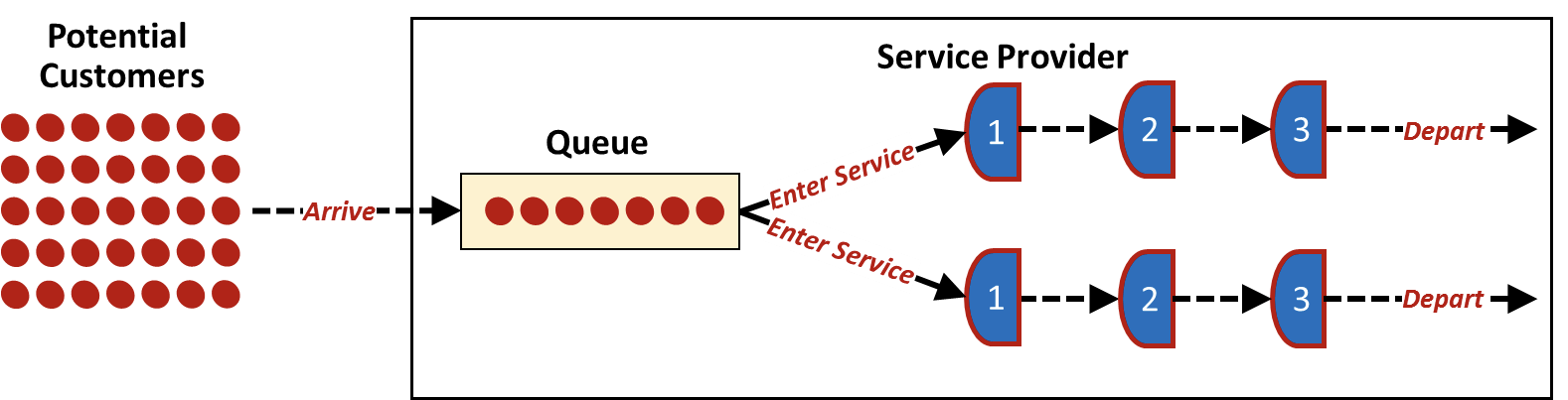

Queuing system design

Single channel, single phase, single server

Ex.: customer to service representative

Single channel, multiple phase - multiple servers acting in series

Ex.: customer, to hostess, to wait staff, to chef

Multiple channel, single phase, single server

Ex.: customer, to one of multiple available service representatives

Multiple channel, multiple phase, multiple servers acting in parallel

Ex.: customer, to one of multiple fast food order takers, to fast food cook

3. Managing distribution channels

Distribution channels involve traditional methods and new channels that incorporate new internet technologies

Eatertainment - combines restaurant and entertainment elements

Ex.: Medieval Times, Rainforest Café, Dave & Busters

Entertailment - combines retail with entertainment elements

Ex.: Mall of America has a ferrous wheel, rock climbing wall, fashion shows, play area

Edutainment (infotainment) - combines learning with entertainment to appeal to customers looking for substance along with play

Ex.: Epcot Center, Liberty Science Center

Franchising - allows business to expand quickly in dispersed geographic markets, protects existing markets, and builds market share and facilitates business when owners have limited financial resources

Ex.: fast food restaurants, temp agencies, tax businesses

International expansion - operate / partner with firms familiar with the region’s markets, suppliers, infrastructure, government regulations, and customers

Must address language and cultural barriers

Internet distribution strategies

Internet retailing is growing faster than traditional retailing

Primary advantages of the Internet include the ability to offer convenient sources of real-time information, integration, feedback, and comparison shopping

Pure strategy - many retailers today sell products exclusively over the internet

Ex.: Amazon

Mixed strategy - using internet as a supplemental distribution channel

Ex.: Walmart

5 dimensions of service quality

Reliability - consistently performing the service correctly and dependably

Responsiveness - promptly and timely service

Assurance - ability to convey trust and confidence to customers

Empathy - providing caring attention to customers

tangibles - the physical characteristics of the service including facilities, servers, equipment, associated goods, and other customers