OSCM 373 sCh16Scheduling

Overview of Scheduling

Definition: Timing the use of human activities, equipment, and facilities.

Benefits of Effective Scheduling:

Cost savings

Increased productivity

Enhanced customer satisfaction and competitiveness

Scheduling Systems

1. High Volume Systems

Flow System: A repetitive process where all jobs follow the same sequence.

Flow System Scheduling Goals:

Ensure a smooth rate of flow for goods or customers through the system.

Achieve high utilization of labor and equipment, which involves line balancing.

2. Low Volume Systems

Job Shop Scheduling: Scheduling for systems with low volume but many variations in requirements.

Focus on make-to-order products.

Different processing requirements (materials, time, sequence) create a complex scheduling environment.

Firm schedules cannot be established until actual orders are received.

Scheduling Approaches

1. Forward Scheduling

Involves scheduling ahead from a specific point in time.

Example Question: "How long will it take to complete this job?"

2. Backward Scheduling

Scheduling backwards from a due date.

Example Question: "When is the latest this job can start and still be completed on time?"

Loading Strategies

1. Loading Definition

Assignment of jobs to processing centers.

2. Types of Loading

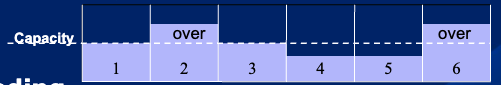

Infinite Loading: Jobs are assigned without regard for center capacity. May lead to overloading (requiring overtime, work shifts, or contracting out).

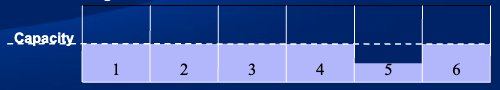

Finite Loading: Jobs are assigned considering center capacity and job processing times.

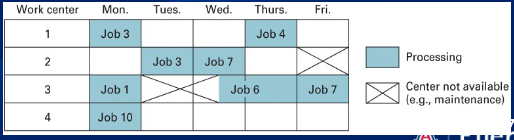

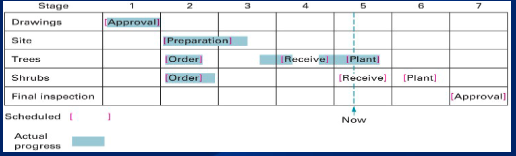

Gantt Charts

Definition: A visual aid for loading and scheduling, displaying actual or intended resource use in a time framework.

Managers use for trial and error schedule development

require constant updating

Types:

Gantt Load Chart: Shows loading and idle times for machines/departments.

Gantt Schedule Chart: Displays jobs in progress and their scheduling status.

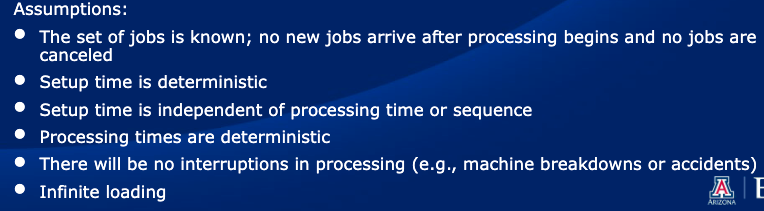

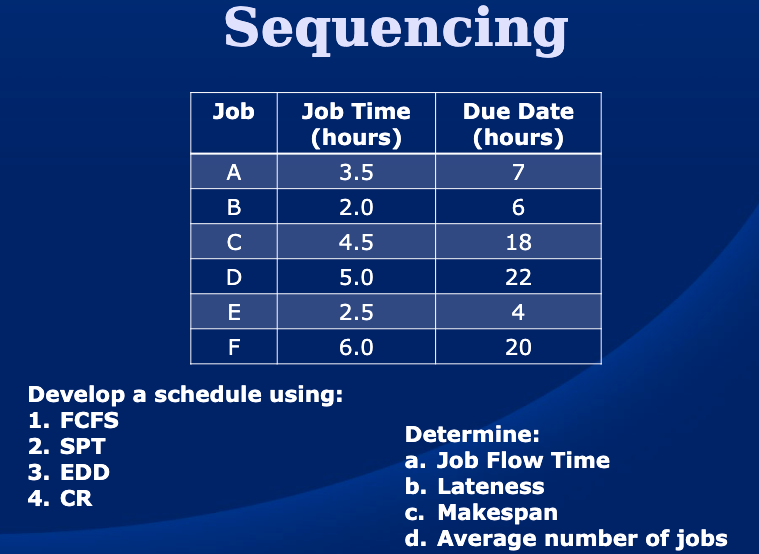

Sequencing

Definition: Determines the order of jobs processed within a work center.

Priority Rules: Heuristics for selecting job processing order.

Priority Rules

FCFS (First Come, First Served): Jobs processed in arrival order.

SPT (Shortest Processing Time): Jobs with the shortest processing time processed first.

EDD (Earliest Due Date): Jobs with the earliest due dates processed first.

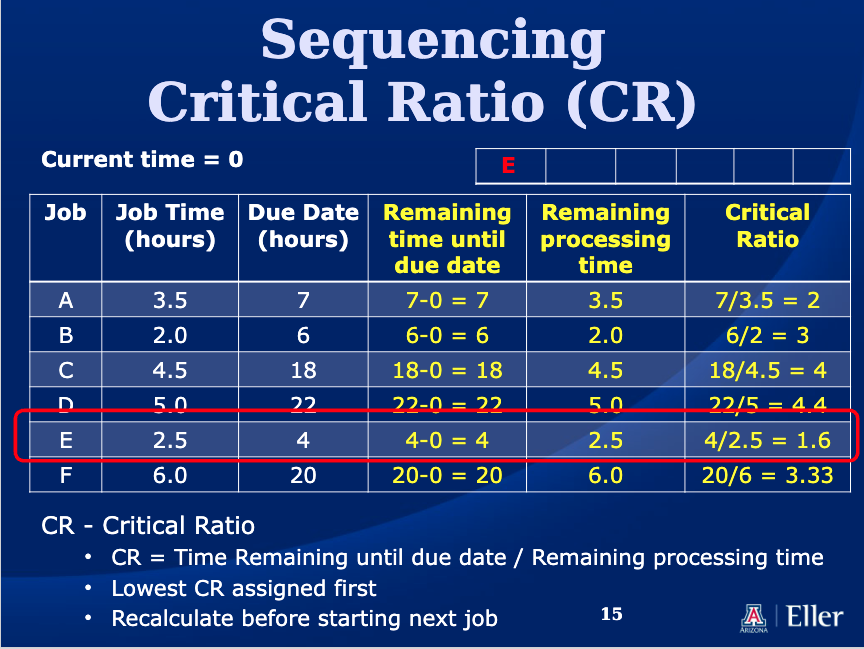

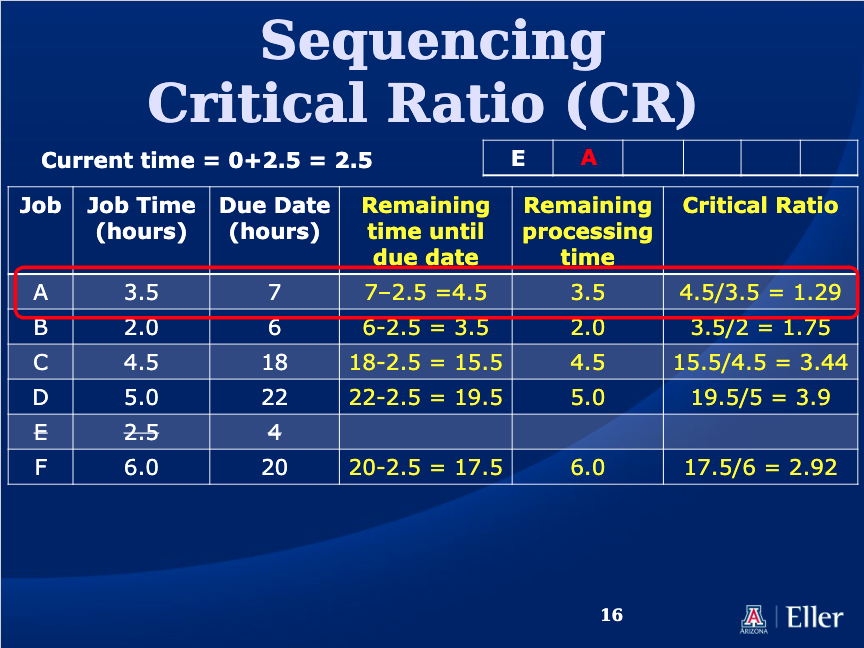

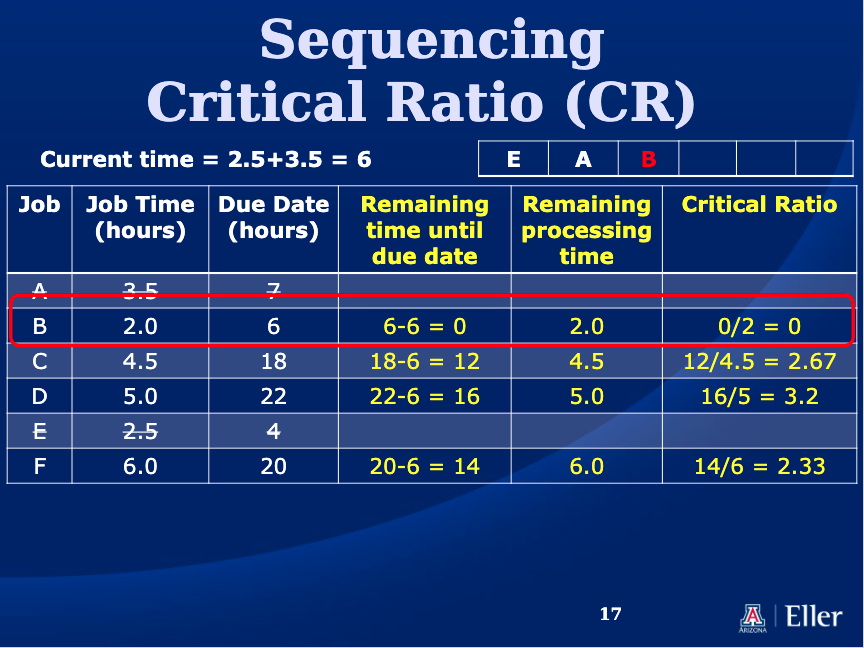

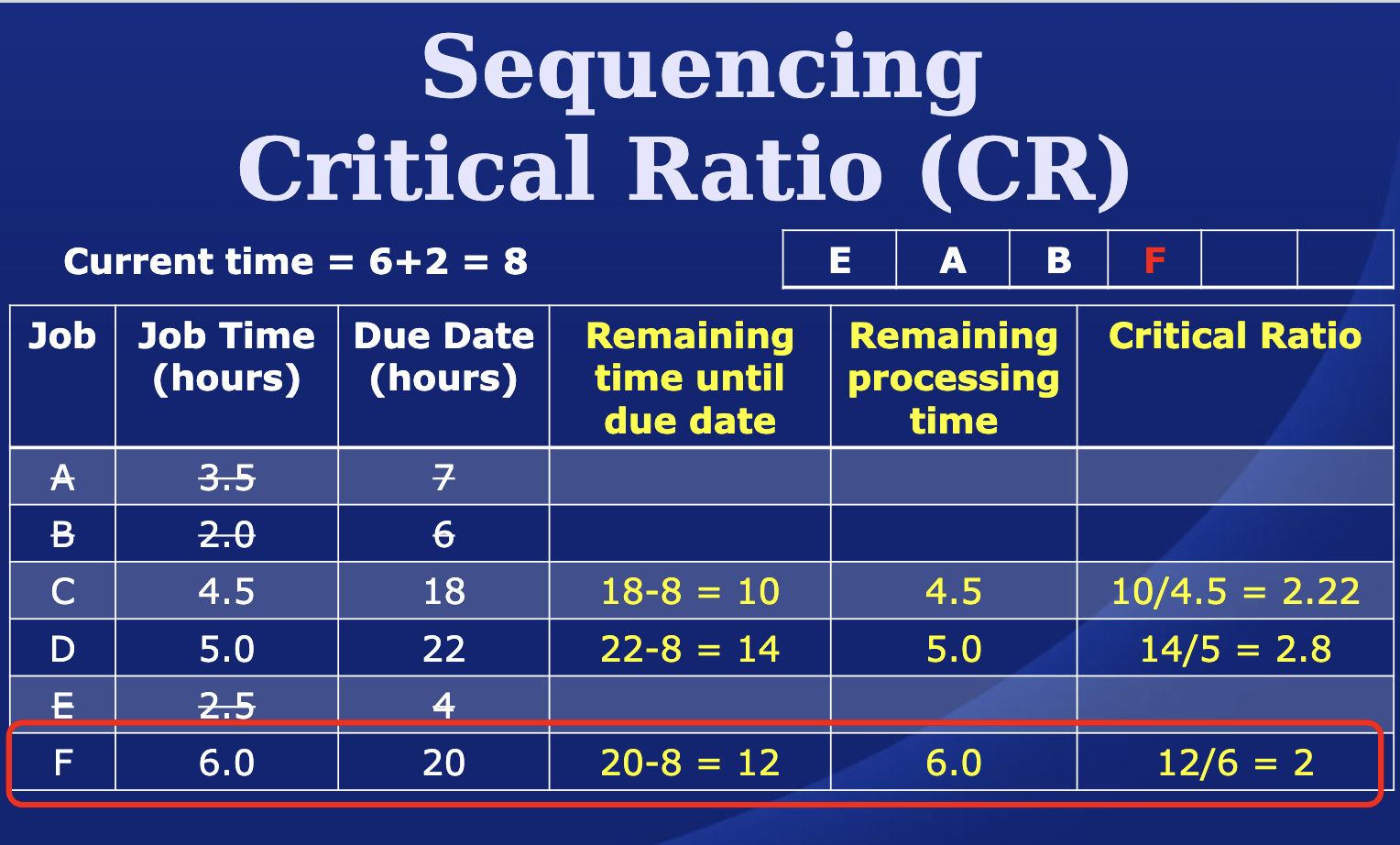

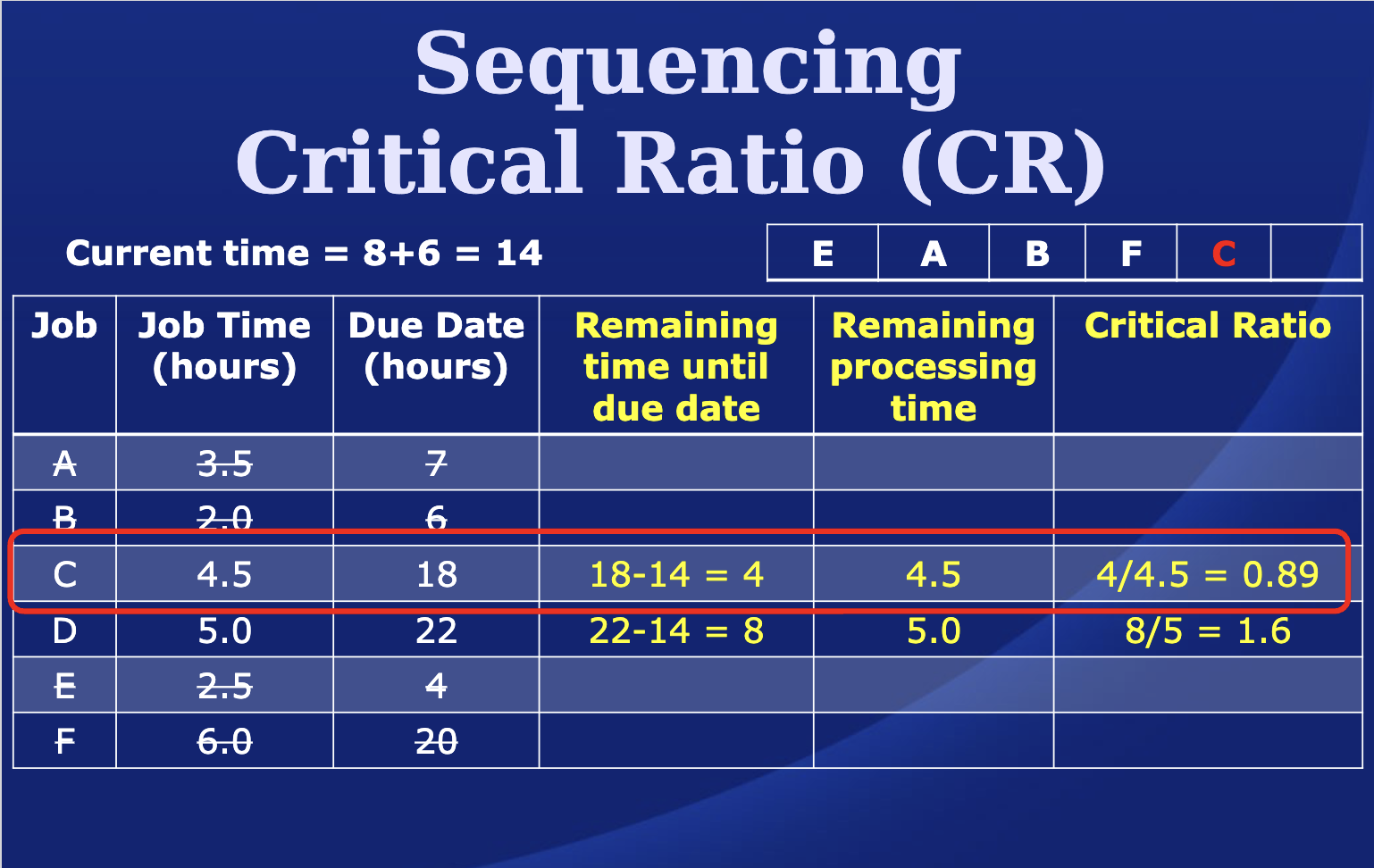

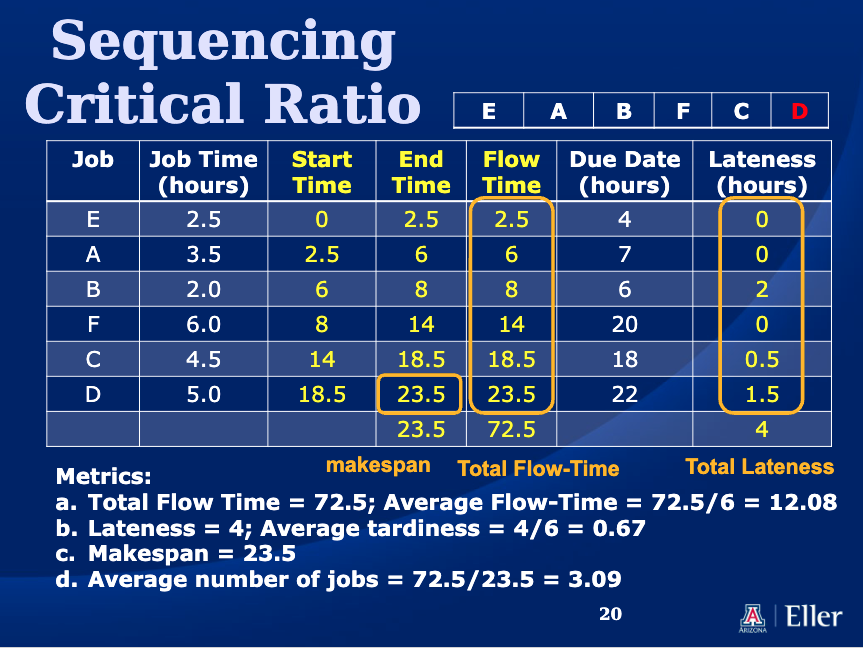

CR (Critical Ratio): CR = Time Remaining until due date / Remaining processing time. Lowest CR is processed first.

S/O (Slack per Operation): Average slack time is calculated. (time until due date - remaining processing time)/ remaining number of operations

RUSH (Emergency or rush jobs prioritized.

Sequencing Performance Metrics

Job Flow Time:

Time from job arrival to completion

Includes waiting time on top of processing time

Makespan:

Total time needed to complete a group of jobs from beg to end

Job Lateness:

Measures how much a job exceeds due date.

Average Number of Jobs:

Calculated as total flow time / makespan.

Jobs in shop considered WIP inventory

Application of Sequencing Methods

Examples

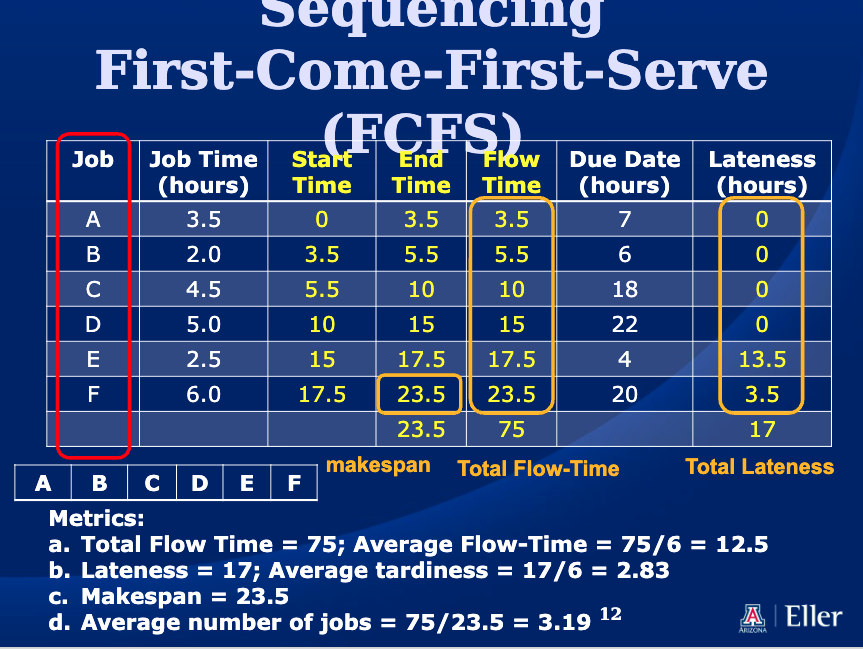

FCFS Example: Computed metrics such as total flow time, lateness, makespan, and average number of jobs.

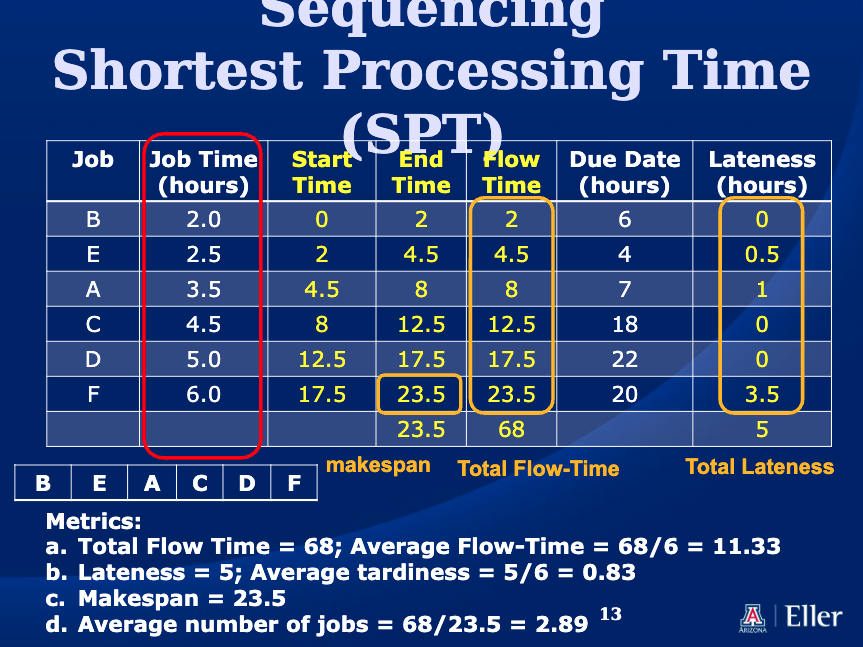

SPT Example: Similar metrics calculated, demonstrating efficiency.

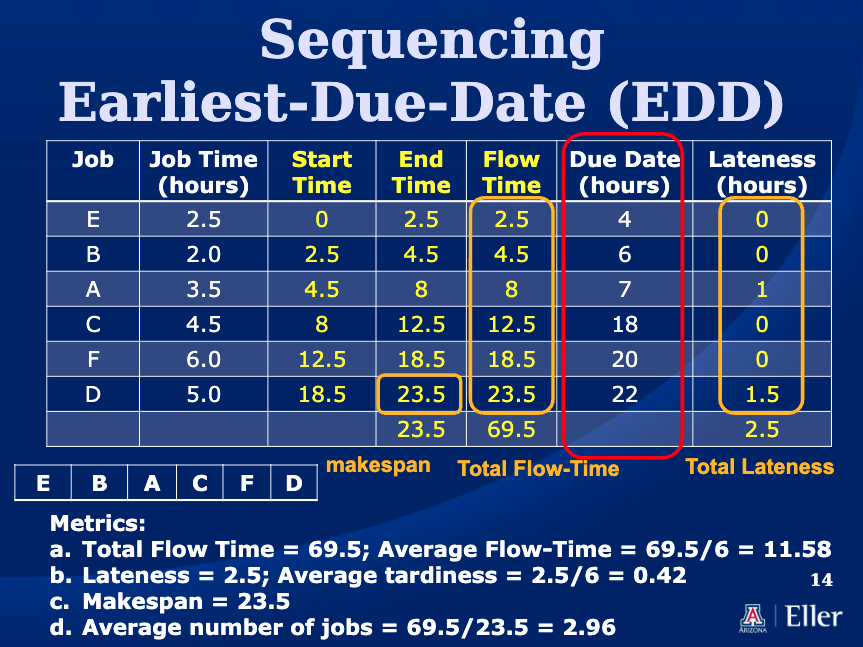

EDD Example: Analyzed to optimize lateness.

CR Example: Jobs sequenced using Critical Ratio with resulting metrics detailed.

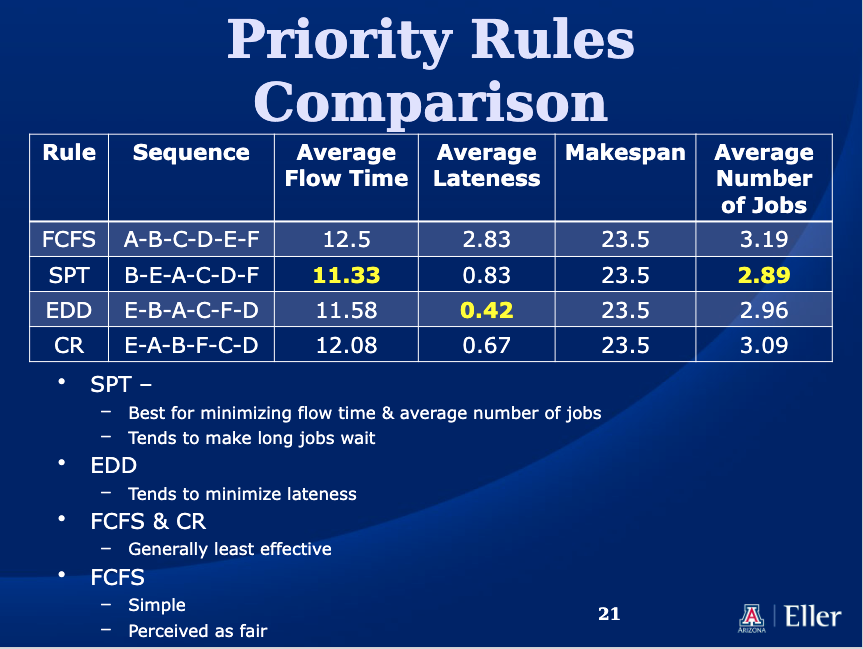

Priority Rules Comparison

Two Work Center Sequencing

Defintion: Must follow same two - step sequence, all jobs must be completed at first work center before moving to second work center

Job time known and constant

Job time independent of sequence

Goal : Minimize makespan

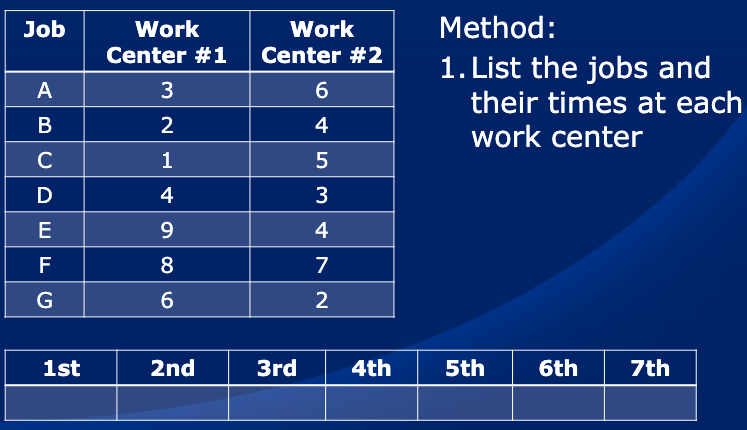

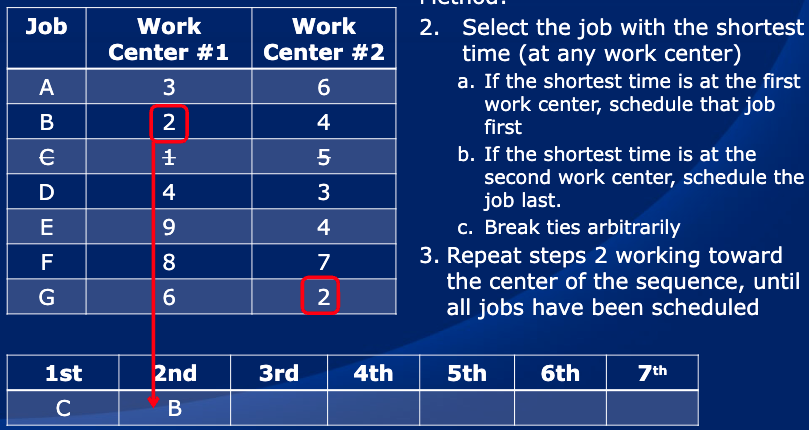

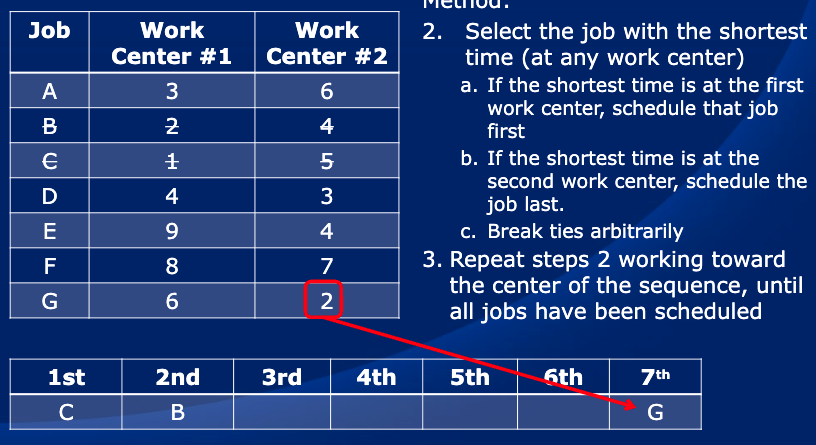

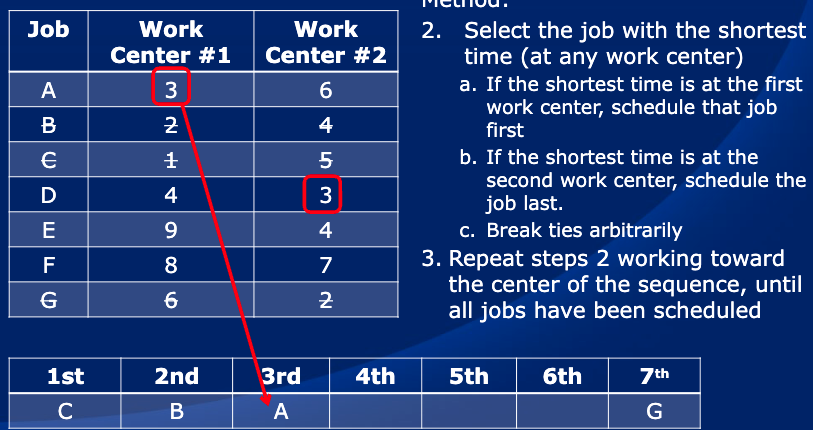

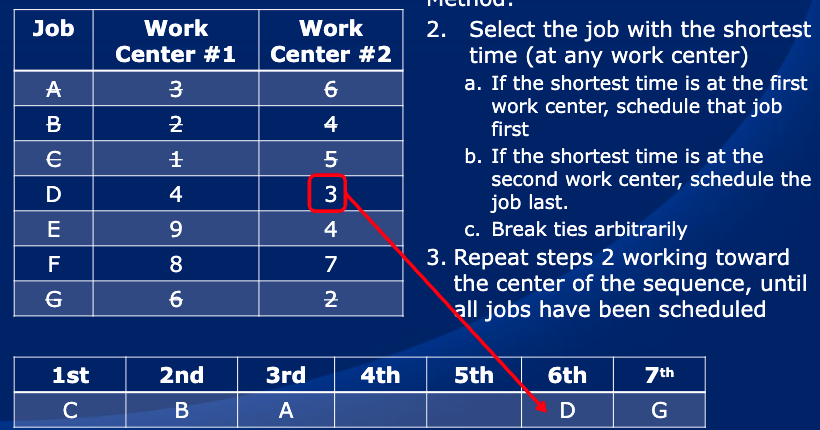

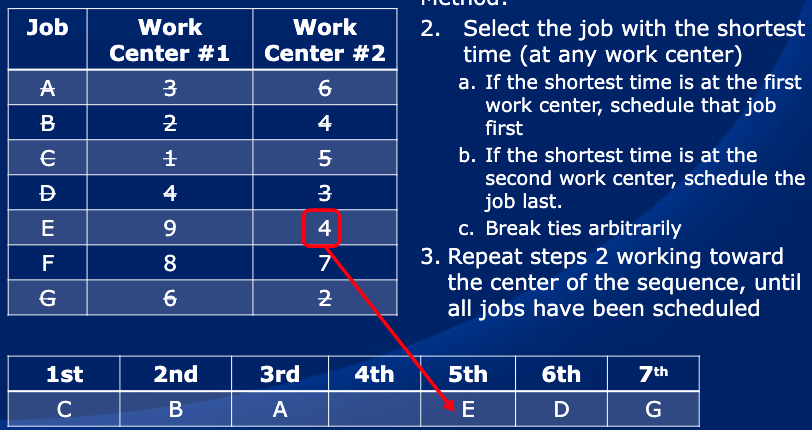

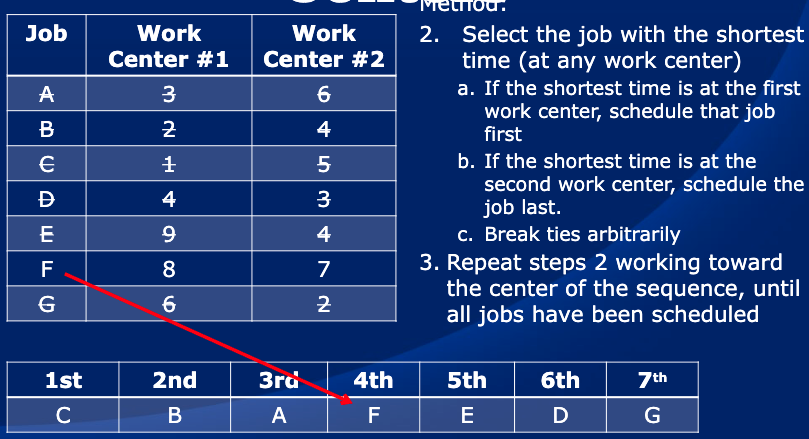

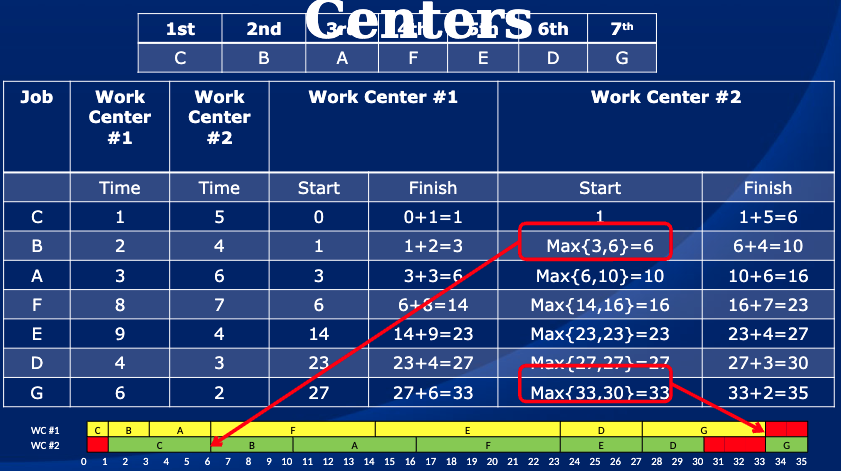

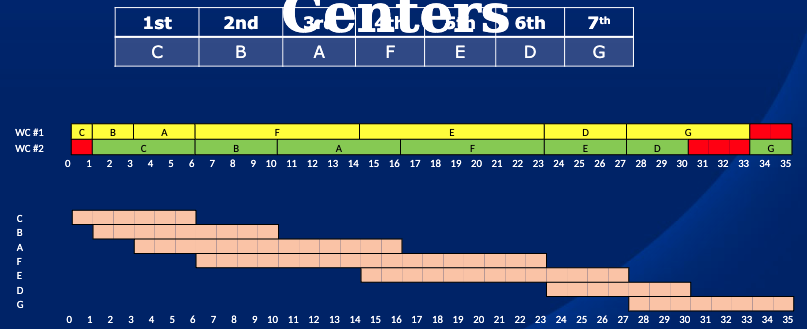

Johnson's Rule

Definition: Technique to minimize makespan for jobs processed at two work centers with the same sequence.

Method:

List jobs and times at each work center

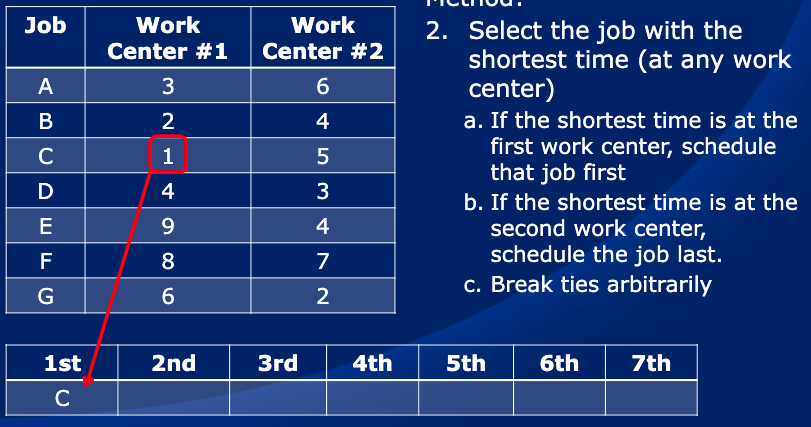

Select job with the shortest processing time for scheduling.

If shortest time is at first wrk center, schedule that job first

If shortest time is at scnd wrk center, schedule that job last

Repeat steps working towards center of the sequence Scheduled until all jobs are processed.

Method Example

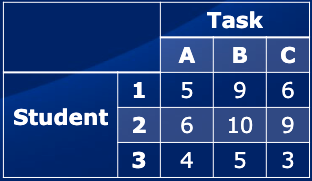

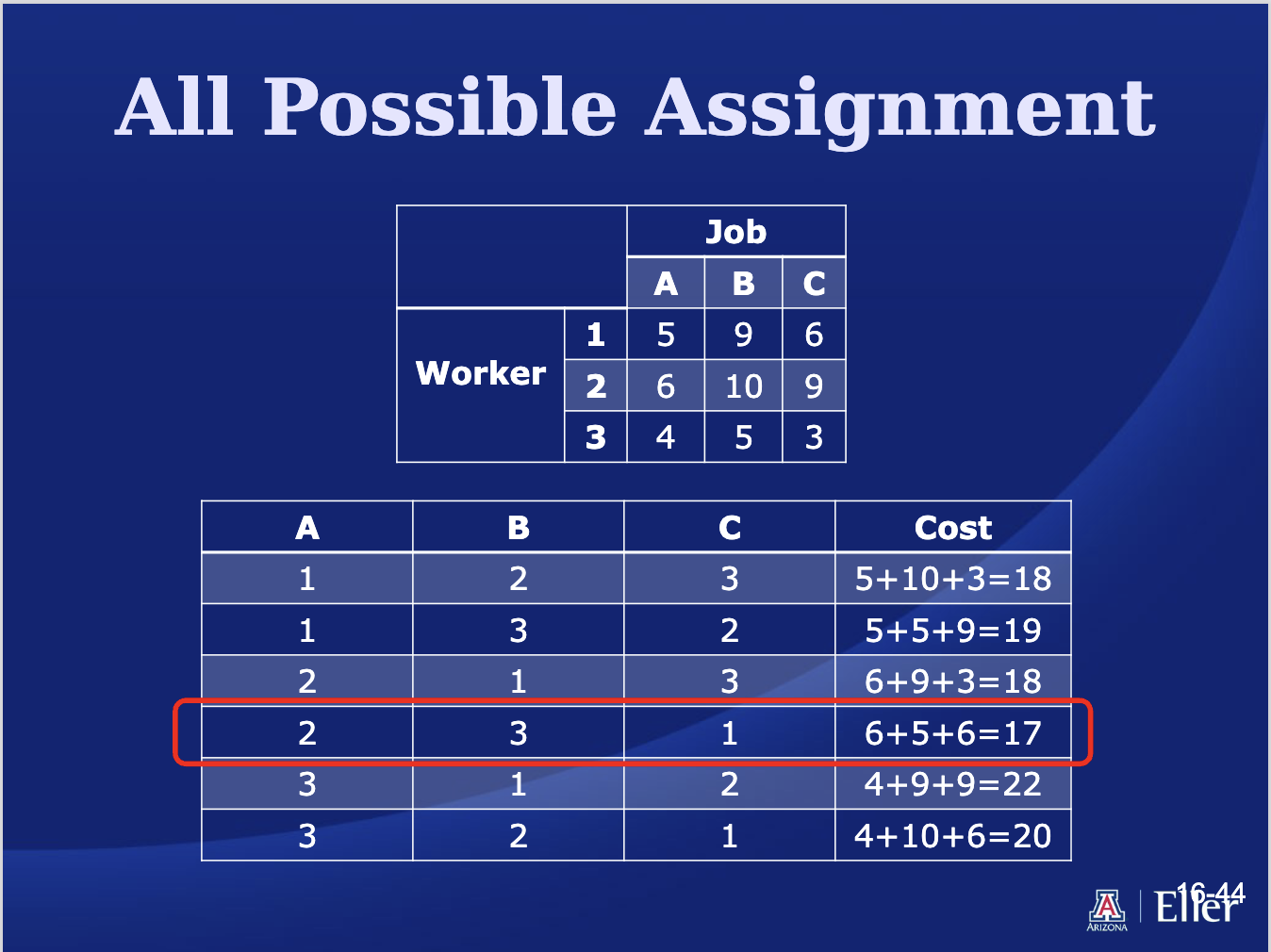

Assignment Model for Loading

Goal:

Optimal assignment of tasks to resources.

Hungarian Method:

Step-by-step method to find the lowest cost solution, including row/column reductions.

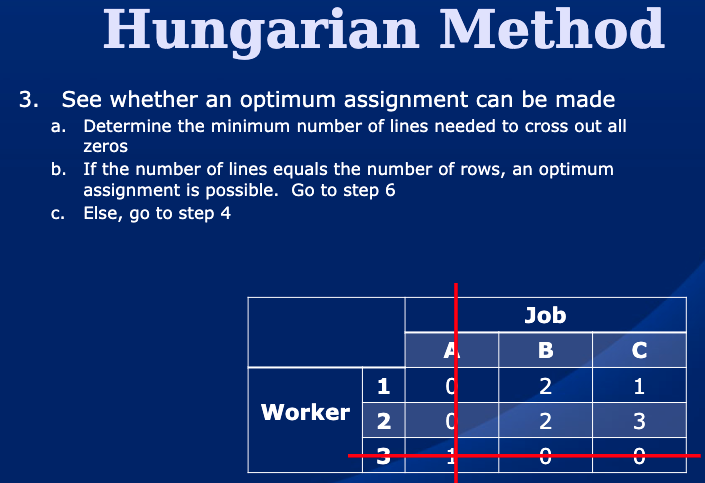

Hungarian Method Steps

Row Reduction:

Subtract smallest number in each row from every number in row

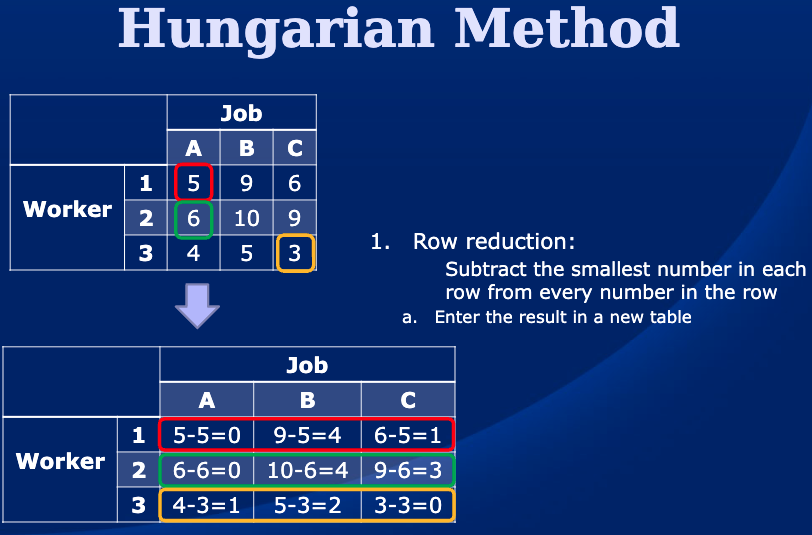

Column Reduction:

Subtract smallest numbr in each clmn from every numbr in clmn

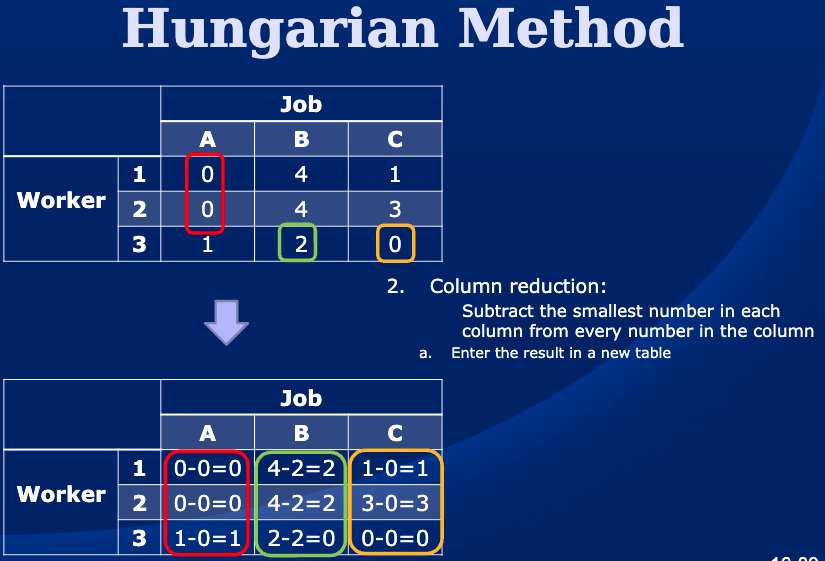

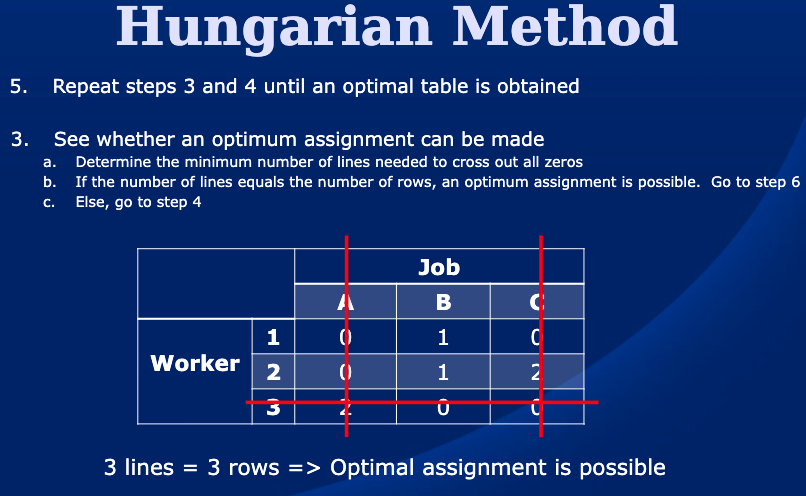

Evaluate whether optimum assignment can be made

Determing minimum num of lines to cross all zeros

if num of lines = num of rows go step 6, if not go step 4

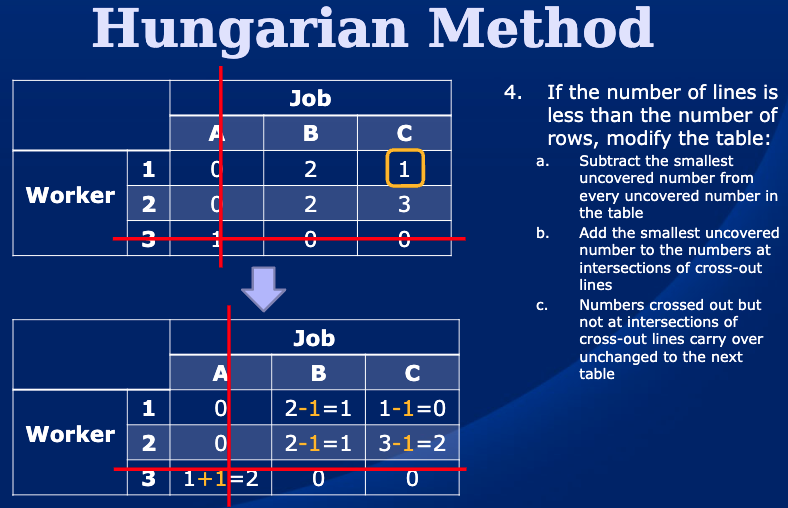

If num of line less than num of rows, modify table

subtract smallest uncovered num from every uncovered num

add smllest uncovered num to nums at intrsct of cross out lines

nums crossed out but not at intersection of cross out lines carrry over unchanged to next table

Repeat steps 3 and 4 until optimal table is obtained

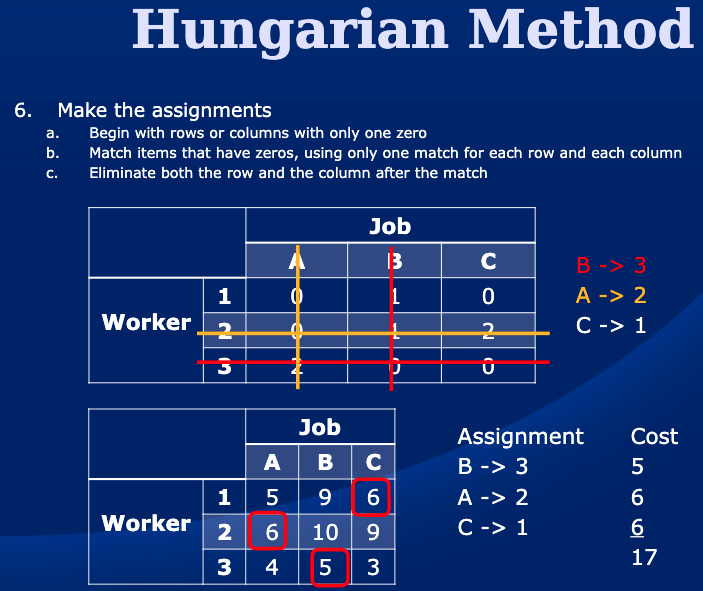

Make assignments

Begin with rows or columns with only one zero

match items that have zeros, using only 1 match for each row and column

eliminate both the row and column after the match

Scheduling Challenges

Challenges include variability in setup times, processing times, interruptions, and job set changes.

No exact method for optimal schedules, making it a challenge for managers.

Strategies to Minimize Scheduling Challenges

Set realistic due dates.

Focus on bottleneck operations to increase capacity.

Schedule according to bottlenecks and consider splitting large jobs into smaller batches.