Section 7

Logistics - The coordination and organisation of complex operations.

Logistics is the process by which products reach where they are needed

Supply Chain Operations- The management of the flow of goods and services

The entire process of moving a product from the supplier of raw materials to the end consumer.

THE COMPONENTS OF LOGISTICS

Forward and reverse flow of goods

Forward-

consists of a flow of operations designed to move a product forwards along a supply chain, from the supplier of raw materials to the end consumer.

Supplier→Manufacturer→Distributor→Wholesaler→Retailer→Consumer

Reverse- consists of all operations involved in returning goods from the end connsumer backwards down the supply chain.

…

Logistics can be separated into a number of key components.

Procurement logistics: selecting suppliers and negotiating contracts for the delivery of raw materials, parts, sub-assemblies and finished goods.

Production logistics: how production is organised, such as the layout of machinery in a factory, and how goods will be produced.

Distribution logistics: how and when goods are delivered.

Disposal logistics (als o referred to as reverse logistics): the reuse of products and materials.

Storage of goods

The storage of goods refers to the process of holding or keeping products, materials, or inventory in a designated space, typically in warehouses, until they are needed for production, distribution, or sale.

Effective storage is a critical component of logistics and supply chain management, ensuring that goods are available when required and are kept safe, secure, and in good condition.

The Japanese "just-in-time" approach minimizes storage by ensuring parts and goods are ready only when needed.

Other supply chain services

Logistics in supply chain management involves coordinating not only the flow and storage of goods but also various related services, such as insuring goods in transit and storage.

Key flows managed by logistics include

Product flow- the movement of goods from the point of origin (such as raw materials from suppliers) to the final destination (the customer)

Financial flow (payments and payment terms)- the movement of money within the supply chain, encompassing the flow of payments, financing, and credit between different entities

Information flow (tracking orders)- to the transfer and communication of data and information between various entities involved, such as suppliers, manufacturers, distributors, retailers, and customers.

Risk flow (insurance coverage)- to the movement and management of potential risks that can affect the various stages of the supply chain, from suppliers to customers. Managing risk flow involves identifying, assessing, mitigating, and monitoring these risks to minimize disruptions and financial losses in the supply chain.

KEY ACTIVITIES IN SUPPLY CHAIN OPERATIONS

Transformation of natural resources

Movement and storage of raw materials

Processing of raw materials and components into finished goods

Storage of work-in-progress and finished goods

Delivery of finished goods

LINKS IN THE CHAIN OF DISTRIBUTION

Distribution- Refers to the storing and moving of products to the customers through various channels.

Distribution channels- the route used to physically get the product from manufacturer to end consumer.

Members of the distribution channel

Manufacturer- maker of the product

Wholesaler- purchasing/holding the products in large quantities and breaking bulk into smaller packs for retailers

Retailer- sells the product directly to the consumers in small quantities.

Consumers- the final buyer of the product

TRANSPORTATION

Transportation is the movement of property or goods to one location or another through different means eg air, cable, road, sea and space.

Factors to consider in selecting method of transportation

Nature of the goods- different products have different features which will affect the type of transportation chosen eg eggs may need a refridgerated truck.

Speed- perishable goods such as fruits may require a fast means of transport. so the speed is important.

Cost

Size and weight

Modes of transportation

Rail

ADVANTAGES

Schedules are reliable

Bulky goods are cheaper to transport by rail

DISADVANTAGES

unsuitable for short distances

Timetables are less flexible

Pipeline

Road

ADVANTAGES

Roads enable door-to-door delivery from supplier to customer

Roads are (mostly) open 24 hours a day, making the scheduling of journeys much simpler than for other forms of transport

Roads enable the carriage of small cargoes (eg. in a van) as well as substantial loads (e.g. by container lorry)

Road transport is highly flexible, with route planners able to choose routes and timing

DISADVANTAGES

There is a limit to the weight that can be carried

Goods in transit can be held up by traffic/congestion

For long distances it is slower and more expensive

Air

ADVANTAGES

It is relatively cheap for expensive items such as jewellery, cosmetics and high-price garments

• It is relatively cheap for sending small and light items, such as cellphones, watches and jewellery

• It is a very fast method of delivery, particularly where little paperwork is required

• It avoids the need for several handlers (transport companies), as a flight can go directly from point A to point B very quickly

• Most Caribbean countries have an airport

DISADVANTAGES

-The cost of sending bulkier items will be high

• Flights to smaller countries in the Caribbean may be infrequent

Sea

ADVANTAGES

• It enables the carriage of very large loads (cargo as well as tourists)

• It avoids the hold-ups associated with land transport

• It is a relatively cost-efficient way of transporting goods and materials

• It is a good way to carry loads that are bulky, not perishable and not required urgently, e.g. iron ore or oil. It is also a good way of carrying containers over long distances. Extremely large loads can be transported on a container ship.Cheaper for goods

DISADVANTAGES

• It has a longer delivery time

• Bad weather at sea can impact on delivery times, and possibly cause cargo damage

• It is not easy to identify the exact location of cargo while it is in transit

• Customs and excise restrictions might mean that goods need to be checked at several ports before they reach their final destination

• It can be expensive

Digital delivery

Transportation Documents

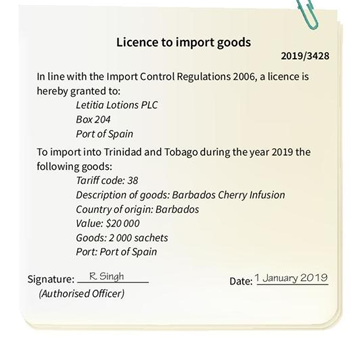

IMPORT LICENSE

A permit from a government body giving permission for goods to be imported into a country

purposes

such as firearms and animals

Restrict the outflow of foreign currency

Protect local industries from foreign imports

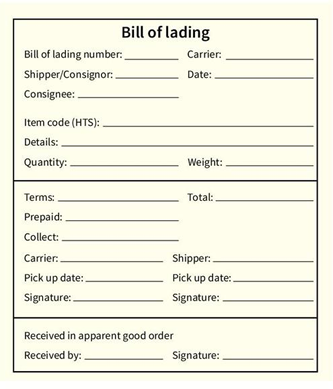

BILL OF LADING

A document that needs to be signed by a carrier to form a receipt for the goods it will be carrying

Purposes:

It is a receipt for the goods .

It is a document of deed of title to show who owns the goods.

Evidence of a contract to transport goods.

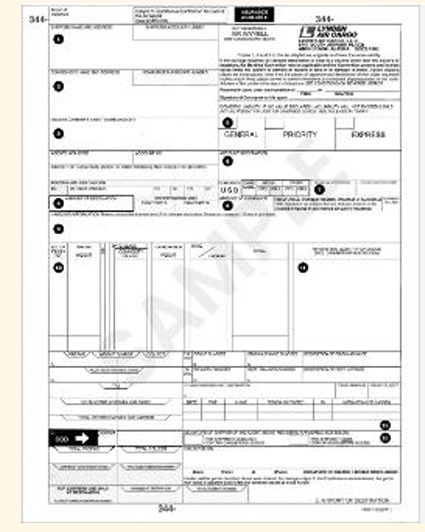

AIRWAY BILL

The air-transport equivalent of a bill of lading

purpose

It is a receipt issued by an airline for goods to a particular destination

Evidence of a contract between shipper and carrier to transport goods

Role of transport in marketing

Fast-track the sourcing of commodities: this ensures that the commodities required in the production process can be transported to the manufacturer/processor as rapidly as possible.

Ensure security of supply: manufacturers and processors cannot afford to wait for deliveries of raw materials and components.

Reduce costs: when transport is organised efficiently, costs of distribution are minimised, enabling businesses to be competitive. Transport is one of the major costs involved in most goods.

ADVANTAGES OF SUPPLY CHAIN OPERATIONS

Fast order processing

Accurate order processing

Lower cost of transport and warehousing

Better management of stock and inventory

Better communication with customers

Higher revenues and profits for business

CHALLENGES OF DEVELOPING AN EFFECTIVE SUPPLY CHAIN OF OPERATIONS

Globalisation- concerned with developing effective supply chains across the globe, bringing together networks of factories and the sourcing of materials on a global scale

Counterfeiting- the false labeling of products, the false use of trademarks and trade names, and the use of inferior materials in goods that are passed off as the real thing.

Product Complexity- The greater the product complexity, the greater the chance of issues in the supply chain. This is because there is a greater chance that one or more parts will not be available when they should be.

Regulatory Complexity

Management Blunders

Changing Market Conditions

Natural Disasters

Political Instability

IMPACT ON BUSINESS COMPETITIVENESS

Competitive Advantage

A business gains an edge over rivals by offering either higher-quality goods/services or lower-cost products. Efficient logistics support this by ensuring goods are in perfect condition and delivered on time for high-quality providers, or by minimizing unnecessary costs for low-cost providers

Comparative Cost Advantage of Outsourcing

Outsourcing involves hiring external companies to handle operations like transport and delivery. This can reduce costs as third-party providers are specialized, have dedicated staff, and possess established supply processes.

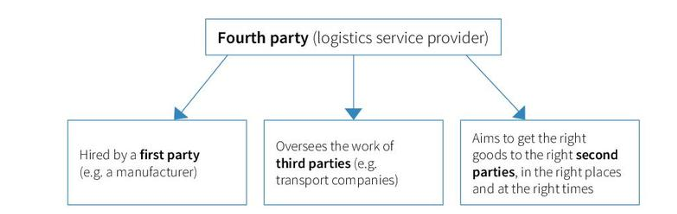

Third-Party Logistics: In outsourcing, the company hiring the logistics provider is the "first party," the customer is the "second party," and the external company handling logistics is the "third party." Specialized third party providers can handle tasks like transporting goods more efficiently.

Fourth-Party Logistics: These providers manage most of the supply chain for companies, covering everything from transport to customs. Their expertise allows manufacturers to focus on production while leaving logistics to experts with advanced IT systems

PROBLEMS IN DISTRIBUTION

Delayed shipment – may arise due to reasons such as unavailability of materials and parts and poor weather conditions

Spoilage – refers to good that has been spoilt in transport particularly with food stuff. This can result from insufficient packaging and poor handling facilities

Misdirection – Improper labelling and inadequate paper works can lead to goods being sent to unintended locations.

Inadequate warehouse facilities – includes having sufficient space, good handling equipment, a clear organisation of goods at the right temperature especially for frozen goods.

Lack of Proper security – Includes fenced ports and handling facilities, security personnels, cameras and overall safe locations to handle goods

Industry unrest – Industrial actions such as a strike can affect distribution

Ineffective Communication – This includes lost paperworks, in accurate filing, wrong documents sent to clients and mistakes on invoices.

MITIGATING PROBLEMS

Government Intervention – The government can create opportunities to assist with improved supply chain management. For example, build bigger ports .

Communication network, Including the Internet – Modern logistics systems are highly dependent on IT to carry out tasks such as managing payment systems , creating paperworks, coordinating transports and other online programmes

Insurance – Distributors may insure their stocks while being stored and transported. Natural disasters may affect storage facilities , theft is another factor and accidents while good are being transported

Selecting the most appropriate channels of distribution based on the product – Distributors should constantly evaluate modes of transport used to transport goods to ensure they can provide quality and on time services at the lowest possible cost.

Use Handling Service with a good reputation– Handling services such as transport firms, ports, import and export agents all provide support in the supply chain operations. Using handling services with good reputation gives companies peace of mind that their goods are in safe hands.

Careful labelling and documentation – Clear labelling ensures that the right products are sent to the right locations. Appropriate documents such as bill of lading, invoices , airway bill etc should be error free to prevent delays during shipments.

Avoiding Large Stocks – Stocks can be handles more efficiently in stock yards if they are arranged properly in smaller piles. Distributors should ensure they deliver raw materials, unfinished goods, and finished goods in a timely to keep stock at minimum quantity.

Increase in Security – Proper security of warehouse and storage facilities helps to prevent and reduce pilfering and damage to company property. This can help to deter theft and also help to support cases in case of a lawsuit.

IMPACT OF TECHNOLOGY

Global Positioning System- allows people to pinpoint their exact positon using satellites that orbit the Earth. able to track packages in real time

Geographic Information System: a computer-based system designed to capture, store, manipulate, analyse, manage and present all types of geographical data, often in the form of a map.

Portnet: a system that uses advanced IT to support shipping and port authorities via the Internet.

Telemarketing: selling goods over the telephone.

Global logistics provider: a large, multinational company set up for the purpose of managing distribution networks across the globe.

Logistics Hub: a location that acts as a centre for a range of activities relating to transport, logistics and goods distribution, both for national and international purposes