WASTEWATER ENGINEERING 2

Wastewater Engineering

Microbiology of Sewage

Biological digestion converts sewage from a contaminated liquid into a stable sludge and harmless effluent.

Microorganisms are significant in water and wastewater due to their roles in disease transmission.

Domestic wastewater contains enormous quantities of microorganisms.

Bacterial counts in raw sewage may range from 500,000 to 5,000,000 per mL, depending on sewage age and water dilution.

Bacterial Growth Pattern

Bacteria: Single-celled plants that metabolize soluble food and reproduce by binary fission.

In a suitable environment, bacteria exhibit a specific growth pattern:

Lag Phase: Adjustment phase of microorganisms.

Log Growth Phase: Microorganisms multiply due to ample food supply.

Declining Growth Phase: Food is largely depleted, becoming a limiting factor.

Stationary Phase: Food supply equals microorganism quantity (food = microorganism).

Endogenous Phase: Microorganism mass decreases as cells use stored reserves and die (F/M < 1).

Lysis: Nutrients from dead cells diffuse to feed remaining cells (cryptic growth).

Bacterial Growth Process

Lag Phase

Log Phase

Stationary phase

Death phase

Types of Bacteria According to Oxygen Requirement

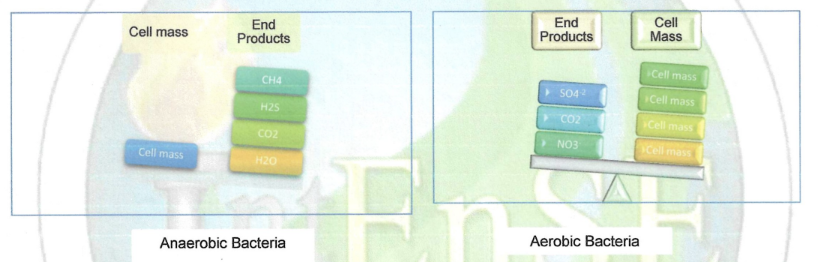

Anaerobic bacteria: Oxidize organic matter using electron acceptors other than oxygen, producing CO2, H2O, H2S, CH4, NH3, N2, and reduced organics.

A large part of available energy appears in the form of end products, hence cell production is low.

End products of anaerobic fermentation are likely to be odorous.

Production of a stable effluent is unlikely, since wastes do not contain sufficient electron acceptors to permit oxidation.

Aerobic bacteria: Utilize free oxygen as an electron acceptor.

End products: CO2, H2O, SO4^{-2}, NO3^{-} , NH3, and more bacteria.

Bulk of available energy is converted into either cell mass or heat, yielding a stable effluent which will not undergo decomposition.

The oxygen required may be furnished naturally from the atmosphere or mechanically by bubble aeration.

Facultative bacteria: Can function in both aerobic and anaerobic environments.

They are the major contributor to stabilization of wastewater.

Example reactions: reduction of CO2 to CH4 and oxidation of NH3 to NO_3^{-}

Significant Bacteria in wastewater treatment:

Pseudomonas: Denitrifying bacteria that reduce NO3 to N2, important in biological nitrate removal.

Zooglea: Helps in the formation of flocs in aeration tanks through slime production.

Sphaerotilus natans: Causes sludge bulking in aeration tanks.

Acinetobacter: Stores large amounts of phosphate under aerobic conditions and releases it under anaerobic conditions, useful in phosphate removal.

Bdellovibrio: Destroys pathogens in biological treatment. Preys on other Gram-negative bacteria and feeds on their biopolymers.

Nitrosomonas: Nitrifying bacteria that converts NH4 into NO2. It is a chemoautotrophic bacteria. very useful in bioremediation.

Nitrobacter: Transforms NO2 to NO3.

Other Significant Microorganisms

Algae

Photosynthetic microorganisms which can produce oxygen and organic cell mass from inorganic chemicals.

Algae are not important in most waste treatment process but play a role in oxidation ponds.

Protozoa

Single-celled protists which reproduce by binary fission. They can be aerobic, anaerobic, or facultative.

Their major food source is bacteria.

Protozoa of importance to sanitary engineers include amoebas, flagellates, and free-swimming stalked ciliates.

Fungi:

Multicellular non-photosynthetic plants. Most fungi are aerobic, but anaerobic species are known.

They tend to predominate over bacteria in wastes which are deficient in nitrogen or low in pH.

Their large filamentous shape makes them to settle poorly and are thus difficult to remove by sedimentation.

Rotifers

The simplest multicellular animal. They feed on bacteria and small protozoa, thus further stabilizing the waste.

Since they require a high level of DO, their presence is a good indication of the relative stability of a treated waste.

Crustaceans

Microscopic organisms characterized by a rigid shell structure.

They are multicellular animals that are strict aerobes, and as primary producers they feed on bacteria and algae. They are important as a source of food for fish.

Additionally, microscopic crustaceans have been used to clarify algae-laden effluents from oxidations ponds.

Bacteria

*Single-celled prokaryotes which metabolize soluble food and reproduce by binary fission.

They may be aerobic, anaerobic, or facultative. They can cause disease, but some are important in pollution control.

Most bacteria require organic food to survive and multiply. Plant and animal material that gets into the water provides the food source for bacteria. Bacteria convert the food to energy and use the energy to make new cells. Some bacteria can use inorganics (e.g., minerals such as iron) as an energy source and can multiply even when organics (pollution) are not available.

Protozoa

Protozoa: Single-celled eukaryotes that show characteristics usually associated with animals.

Protozoa are responsible for improving the quality of the effluent, maintaining the density of dispersed bacterial populations by predation.

In wastewater treatment, protozoa are a critical part of the purification process and can be used to indicate the condition of treatment processes.

Algae

Algae: Plants, many microscopic, containing chlorophyll. Freshwater algae are diverse in shape, color, size, and habitat.

They are the basic link in the conversion of inorganic constituents in water into organic constituents.

Algae and cyanobacteria typically grow in the aerobic zone and provide bacteria in the pond with plenty of oxygen during the daytime.

However, algal photorespiration may consume oxygen during night-time when it is dark.

Algae can be used in wastewater treatment for:

Removal of coliform bacteria.

Reduction of both chemical and biochemical oxygen demand.

Removal of N and/or P.

Removal of heavy metals.

Fungi

Fungi: Simple plants lacking in ability to produce energy through photosynthesis. Fungi are eukaryotes and have a complex cellular organization.

Fungi are indicated for their superior aptitudes to produce a large variety of extracellular proteins, organic acids, and other metabolites, and for their capacities to adapt to environmental constraints.

Virus

Virus: The smallest form of microorganisms (others classify it as particle and not as microorganism) capable of causing disease.

Viruses are a major hazard to public health. Some viruses can live if 41 days in water and wastewater at 20 °C. The cause of lots dangerous diseases.

More attention must be paid to viruses, however, when surface water supplies have been used for sewage disposal. Viruses are difficult to destroy by normal disinfection practices, as they require increased disinfectant concentration and contact time for effective destruction.

Rotifers

Rotifers make up a well-defined group of the smallest, simplest multicellular microorganisms and are found in nearly all aquatic habitats.

Rotifers are a higher life form associated with cleaner waters. Normally found in well-operated wastewater treatment plants, they can be used to indicate the performance of certain types of treatment processes.

Generally speaking, microorganisms are like people who prefer:

Enough room to move around

Just sufficient food

Enough nutrients

Enough oxygen to breath

Coliform Organisms

Coliform Organisms are rod shaped bacteria thriving inside the intestinal tract of man.

Each person discharges from 100 to 400 billion coliform organisms per day.

They are harmless to man and are, in fact, useful in destroying organic matter in biological waste treatment processes.

The presence of coliform organisms is taken as an indication that pathogenic organisms may also be present, and the absence of coliform organisms is taken as an indication that the water is free from disease producing organisms.

Total Coliform - all aerobic, facultative and anaerobic gram-negative, non-spore forming, rod-shaped bacteria that ferment lactose with gas formation within 48 hours

Coliform Organisms

include the genera Escherichia and Aerobacter.

Other genera: Citrobacter, Hafnia, and Klebsiella

There is difficulty in determining E.coli to the exclusion of the soil coliforms; as a result, the entire coliform group is used as an indicator of fecal pollution.

E.coli

it is the preferred pathogen indicator. Note: this is not the pathogenic E.coli O157:H7 strain.

Properties of E.coli are:

Found in much higher concentrations than most pathogens in fecal matter.

Non pathogenic

Easy detect, relatively fast and inexpensive analysis.

Its absence indicates absence of enteric pathogens

Test Procedure for determining the presence of coliform:

Presumptive test - based on the ability of the coliform group to ferment lactose broth, producing gas.

Confirmed test - consist of growing cultures of coliform bacteria on media that supress the growth of other organisms.

Accepted Methods for determining the number of Coliform organisms

Most Probable Number (MPN) - based on a statistical analysis of positive and negative results from testing multiple portions of equal volume.

MPN is NOT an absolute concentration of organisms.

Membrane Filter Technique (MFT) - Passing water sample through a membrane filter retaining bacteria.

The bacteria are reatined on the filter.

The bacteria are then contacted with an agar that contains necessary nutrients necessary for growth of the bacteria. After incubation, the coliform colonies can be counted and the concentration in the original water sample is determined.

Faster than MPN and gives a direct count of the number of coliforms

Fecal Coliforms (FC) vs. Fecal Streptococci (FS)

The quantities of fecal coliforms and fecal streptococci discharged by human beings are significantly different from the quantities discharged by animals.

FC/FS ratio:

Domestic Animal: Less than 1.0

Human being: Greater than 4.0

Objectives of Sampling

Evaluate performance efficiency of WTP

Compliance to DENR requirements

Sampling Techinques

Grab Sampling - sample is taken at random with no particular time.

It may be taken from the discharge of a pump, be manually dipped from the flow, or be automatically dipped or siphoned from the stream.

Composite Sampling - is a mixture of grab samples taken over a period of time, with the volume of individual samples usually being proportional to the flow at the time the sample is taken.

Composite samples are most useful for analyses of average characteristics such as daily waste loads

Continuous Sampling - sample represents diversion of a small fraction of the total flow over some period of time.

Continuous samplers are usually not flow proportional. Rather, they extract the sample at a constant rate.

Continuous samplers are most suitable for instrumental measurements which can be performed virtually instantaneously, such as temperature, pH, DO, etc.

Important Notes on Sampling

Examination of drawings that shows sewers and manholes will help to determine sampling locations where flow conditions encourage a homogenous mixture.

However, if the discharger intends to evaluate the performance efficiency of the whole WTP, samples must be taken from influent stream to the WTP and from the effluent stream of each treatment unit. Effluent from specific plant operation/process or production area must be taken to evaluate effectiveness of in-plant water pollution control or waste minimization measure/s.

In sewers and in deep, narrow channels, samples should be taken from a point ord the water depth from the bottom. The collection point in wide channels should be rotated across the channel.

Samples must be suitably preserved until they can be analyzed. Domestic sewage samples can be preserved satisfactorily by storage at 4°C. Freezing alters the character of the solids and thus should be avoided.

Composite Sampling Procedure and Calculation Procedure

Determine the total amount of sample required for all tests to be performed on the composite sample.

Determine the average daily flow of the treatment system. Average daily flow can be determined by using several months of data will provide a more representative value.

Calculate a proportioning factor:

Proportioning : Factor = \frac{total : sample : volume : required : (ml)}{# samples : to : be : calculated : x : average : daily : flow : (MGD)}Round off the proportioning factor to the nearest 50 units (50,100, 150, etc) to simplify calculation of the sample volume.

Collect the individual samples in accordance w/ the schedule.

Required : volume : (mL) = Flow : @time : sample : was : collected : x : PF

Mix the individual sample thoroughly; measure the required volume and add it to the

composite storage container.Refrigerate the composite sample throughout the collection period.

Sample Problem

Effluent testing will require 3825 mL of sample. The average daily flow is 4.25 MGD.

Unit Operation & Unit Process

Unit operation - the treatment or removal of contaminant is brought about by the physical or mechanical sources.

Unit process - The treatment occurs predominantly due to chemical and biological reactions.

Classification of treatment methods:

Physical unit operations - treatment methods in which the application of physical forces predominate. Because most of these methods evolved directly from man's first observations of nature, they were the first to be used for wastewater treatment.

Examples of Physical Unit operation:

Screening - Racks or bar screen are the 1st step in WTP. They are used to remove large objects.

Grit Removal - It is used to remove heavy material such as sand, gravel, eggshell, etc.

Primary Sedimentation - It is used to remove settleable solids

Filtration - Filtration is used to polish the effluent. Total suspended solids and turbidity are removed.

Reverse Osmosis or ultrafiltration - It is a demineralization process applicable to production of high quality water from effluent. The water is permeated through semipermeable membrane at high temperature.

Chemical unit processes - treatment methods in which the removal or conversion of contaminants is brought about by the addition of chemicals or other chemical reactions.

Examples of Chemical Unit Process:

Chemical Precipitation - Treatment is accomplished by producing a chemical precipitate that will settle.

Adsorption-Removal of specific compounds from the wastewater on solid surfaces using the attraction between bodies.

Disinfection - It is used to to reduce the number of water borne pathogens in the effluent.

Breakpoint chlorination - Ammonia nitrogen is oxidized to nitrogen gas by breakpoint chlorination in a mixing basin.

Biological unit processes - treatment methods in which the removal of contaminants is brought about biological activity or action of microorganisms.

Examples of Biological Unit Process:

Suspended growth biological reactor - It is used to remove dissolved organics. Principal variation is activated sludge.

Attached growth biological reactor - It is used to remove dissolved organics. Principal variation is trickling filter.

Nitrification - The process is used to convert ammonia to nitrate. Achieved in suspended or attached growth biological reactor.

Denitrification - Nitrite and nitrate are reduced to nitrogen gas by microorganisms. It is achieved under anaerobic condition in suspended or attached growth reactors.

Elements of Plant Analysis & Design

Flowsheet - is a graphical representation of a particular combination of unit operation and processes.

Process loading criteria - key criteria used as a basis for sizing the individual unit operation and processes.

Solid Balance - is determined by identifying the quantities of solids entering and leaving each unit operation or process. Such information must be available to (1) assess the need for sludge-storage facilities and their capacity, and (2) to determine the proper size of the sludge piping and pumping equipment.

Hydraulic profiles - used to identify the elevation of the free surface of the WW. These profiles are prepared for (1) to ensure that the hydraulic gradient is adequate for the WW to flow through the treatment facilities by gravity, (2) to establish the head requirement for the pumps where pumping will be needed, and (3) to ensure that the plant facilities will not be flooded or backed up during periods of peak flow.

Plant layout - is the spatial arrangement of the physical facilities of the treatment plant in the flowsheet. The overall plant layout includes the location of the control and administrative buildings and other necessary buildings.

Preliminary Treatment

Provides protection to the WTP equipment that follows. This includes:

Preliminary treatment components:

Screening

Flow measurement

Solids grinding

Grit removal

Equalization

Screening - treatment used for the removal of coarse and settleable solids by inception. The purpose is to remove material which would

Damage equipment

Interfere with the satisfactory operation of a process

Cause objectionable shoreline condition

Types of Screens:

Racks or Bar Screen - composed of parallel bars or rods which maybe hand cleaned or mechanically cleaned

Fine Screen - wire/cloth mesh; perforated plate

Flow Measurement

Flow rate needed for efficient operation, chemical additon, etc

Several operations need flow rate data for good operations (ie. Chlorination, pH adjustment, etc.)

Legislative requirement

Various Types of WW Flowrate used in Process design :

Average Daily Flowrate (ADF)- average flowrate over a period of time

Peak Hourly Flowrate (PHF)- highest flowrate measured in 24-h period.

Maximum Daily Flowrate (MDDF)- maximum daily design flow over a period of time.

Turndown ratio - the ratio of the highest operating flow rate to the lowest operting flow.

Principal flow rate terms and their use in design and operation

Flow rate | Application in Design and Operation |

|---|---|

Average Daily | Base for development of flowrate ratios and for estimating pumping, sludge quantities, and chemical costs; identification of sewers where flows will not achieve minimum velocities. |

Minimum hour | Estimating turndown ratio for pumping facilities and low range for plant flow metering. |

Minimum day | Sizing of plant component (influent channels, biological treatment systems including recycle requirements for trickling filters). |

Minimum month | Selection of minimum operating units required during low flow periods (especially at start-up of new facility); scheduling shutdown for maintenance. |

Peak hour | Sizing of sanitary sewers; sizing pumping facilities and channels; sizing of physical unit operations including bar racks and screens, grit chambers, sedimentatio tanks, filters, and chlorine tanks |

Maximum day | Sizing equalization basins and sludge pumping systems |

Maximum month | Sizing chemical storage facilties |

Sample Problem: Compute the peak hourly flowrate, average hourly flowrate and daily flowrate for the data tabulated at the right side:

Flow measuring devices:

Venturi meter

Parshall flumes

Weir (i.e. V-notch)

Magnetic & Sonic meters

Solids grinding or comminution

grinding of coarse solids to a more or less uniform size.

Comminutors - devices that used to cut up the solids in wastewater.

Barminutor - is a combination of a bar screen and a comminutor. The bar screen traps the rags and a rotating cutter runs down the screen to cut up the rags every 15-30 minutes.

Grit Removal

Grit Chamber - is an enlarged channel where the velocity of wastewater flow is controlled to allow only the heavier solids to settle out.

The downward slope of a sewer line must be sufficient to maintain a minimum velocity of 2 feet per second in the pipe. This velocity is maintained until the flow enters the treatment plant. The grit is removed from the flow as it passes through a grit chamber. The velocity in the grit chamber is reduced to about 1 foot per second.

Variation types: (a) Horizontal-flow grit chamber (b)Aerated grit chamber (c) Circular or Vortex type

Flow Equalization

Equalization basin - maintains a constant volumetric flow of wastewater from pretreatment to other downstream operation. It dampens hydraulic or flowrate variations.

Specific Objectives of Equalization:

Smooth out fluctuations in flow rate

Dampens the variation in the concentration of BOD5, and TSS.

Decrease fluctuations in flow rate, to provide more consistent treatment. Done by storing excess wastewater during high flow periods. Results in more consistent treatment.

Computations on Preliminary Treatment

Screening Removal Calculations

screening : removal : rate = \frac{volume : of : screenings : removed}{day}

Sample Problems:

A total of 65 gallons of screenings is removed from the wastewater flow during a 24-hour period. What is the screening removal reported as cubic feet per day?

During 1 week, a total of 310 gallons of screenings was removed from wastewater screens. What is the average removal in cu.ft/day?

Screening Pit Capacity Calculations

In screening pit capacity problems, the time required to fill a screening pit is calculated. The equation used in screening pit capacity problem is given below:

screening : pit : filling : time : (day) = \frac{volume : of : pit : (cubic : ft)}{screening : removal : rate : (cu. : ft/day)}

Sample Problems:

A screening pit has a capacity of 500 cubic feet. (The pit is usually larger than 500 cu.ft to accomodate soil for covering). If an average of 3.4 cu.ft of screenings are removed daily from the wastewater flow, in how many days will the pit be full?

Grit removal, Grit channel velocity and Settling time

Grit : removal : (cu. : ft/MGD) = \frac{volume : of : grit : removed : (cu. : ft)}{influent : flow : rate}

Grit : velocity= \frac{plant : flow : rate : (MGD)}{No. : of : channels : in : service : x : channel : width x : water : depth}

settling : time = \frac{liquid : depth}{settling : velocity}