CONSTRUCTION TECHNOLOGY 1 LEC 04

CETE 101: Construction Technology 1 Overview

Wood

Defined by the National Structural Code of the Philippines (NSCP) as:

Hard, fibrous tissue found in the stems and roots of trees.

Lumber

Processed wood into uniform sizes, ready for construction.

Types of Lumber:

Rough Lumber: Raw material for multiple uses.

Finished Lumber: Processed wood, ready for use with minimal cutting.

Timber

Defined as square or nearly square sawn lumber, at least 125 mm wide, used in various building parts.

NSCP

The National Structural Code of the Philippines

Key Components of Wood Framing:

Studs: Vertical wood members used in walls

Joists: Horizontal wood members that support floor and ceilings

Rafters: Sloped wood members that support the roof structure

Sills: Horizontal and treated wood members that lay directly on the foundation, and provide base for the wall framing

Headers: Horizontal wood members placed above door and window openings to support the weight from above

Plates: Horizontal wood members at the top and bottom of walls

Sole plate or Bottom plate: Bottom

Top plate: Top

Sheathing: Panels attached to the exterior of the framing to provide structural stability and a base for exterior finishes

Diagonal Subfloor: Provides structural integrity.

Double Joists: Supports weight.

Solid Bridging: Connects joists for strength.

Plywood Subfloor: Acts as a base layer.

Anchored Sill: Secures the structure.

Lapped Joists: Joined at the girder.

Space for Sheathing: Needed in joist arrangements.

Definition of Board Foot

Measurement unit for lumber volume despite metric usage.

1 board foot = 1 sq. ft. x 1 inch thick = 144 cubic inches.

Calculation Example

Volume calculation: 12 in. x 12 in. x 1 in. = 144 cu. in. = 1 board foot.

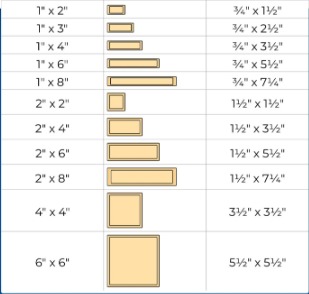

Nominal Sizing

Understanding Sizing Differences

Nominal Size: Original dimensions before drying/planing, used in merchandising.

Actual Size: Smaller, due to drying and planing processes.

Drying: As wood dries, it shrinks in width and thickness.

Planing:The planing process removes up to ¼ inch from both dimensions of the wood.

Examples of Size Reduction:

1" x 2" nominal becomes 3/4" x 1 1/2" actual.

Planing can remove up to 1/4 inch from both dimensions.

According to the National Institute of Standards American Softwood Lumber Standard (PS 20)

Nominal Actual