L18: Solidification defects

Learning Outcomes:

Explain the influence of the solidification mode of an alloy on the distribution of porosity.

Derive the shape of the shrinkage pipe formed in a pure metal solidifying in a cylindrical mould.

Understand why the liquid becomes supersaturated in dissolved gas during solidification, and how this leads to porosity.

Describe the origin of common types of macro segregation.

Influence of Solidification Mode on Porosity Distribution

Key Concept: The way an alloy solidifies (planar, columnar, or equiaxed) affects where and how porosity forms.

Planar Growth:

Porosity forms at the top of the casting.

Caused by shrinkage as the solidification front moves downward.

Equiaxed Growth:

Porosity forms in interdendritic spaces (between dendrites).

Results in microporosity due to isolated liquid pockets shrinking.

Columnar Growth:

Porosity forms between columnar grains.

Caused by shrinkage and gas evolution, leading to macropores.

Heat Flow Direction:

Vertical heat flow: Porosity forms at the top.

Radial heat flow: Porosity forms in a parabolic shape.

Lateral heat flow: Porosity forms along the sides.

2. Shape of the Shrinkage Pipe in a Cylindrical Mould

Key Concept: When a pure metal solidifies in a cylindrical mould, a shrinkage pipe forms due to volume contraction.

Derivation:

Use conservation of mass: Mass loss from the top = mass gain in new solid.

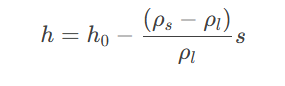

Formula for vertical heat flow:

Where:

h = height of the shrinkage pipe.

ρs = solid density.

ρl = liquid density.

s = solidification distance.

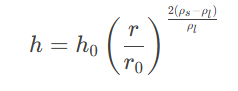

For radial heat flow, the shrinkage pipe shape is parabolic:

Where:

r = radius.

r0 = initial radius.

3. Supersaturation of Dissolved Gas and Porosity Formation

Key Concept: Metals dissolve more gas in the liquid state than in the solid state, leading to gas porosity.

Process:

During solidification, gas (e.g., hydrogen) is partitioned into the remaining liquid.

The liquid becomes supersaturated with gas.

When supersaturation exceeds a critical level, gas bubbles nucleate, forming pores.

Combined Effects:

Shrinkage porosity: Caused by volume contraction during solidification.

Gas porosity: Caused by gas evolution.

Together, they create voids in the solidified metal.

4. Origin of Common Types of Macro segregation

Key Concept: Macro segregation refers to compositional inhomogeneities at the scale of the casting (mm or larger).

Types and Causes:

Gravity-Induced Segregation:

Denser solid phases settle under gravity.

Results in lower solute content at the bottom of the casting.

Solidification Shrinkage-Induced Segregation:

As columnar grains grow, shrinkage causes liquid to be sucked toward the mould wall.

Leads to higher solute content near the surface.

Convection-Induced Segregation:

Thermal and solute convection in the liquid redistributes solute.

Causes macro segregation patterns.

Extreme Case: In some castings, solute-rich liquid can accumulate at the top, creating a strong compositional gradient.

Additional Notes for Revision

Porosity Avoidance:

Degassing: Bubble argon gas through the liquid to reduce hydrogen content.

Feeders: Use feeders to supply liquid and compensate for shrinkage.

Design: Ensure porosity forms outside the casting (e.g., in runners or feeders).

Thermo-Mechanical Effects:

Solidification defects (porosity, macro segregation, cracking) are influenced by:

Thermal contraction.

Gas evolution.

External loads (e.g., in high-pressure die casting).