OSCM 373 sCh07WorkDesignMeasurement

Chapter Overview

Process Flow Charts

Definition: Graphic representation of a process.

Purpose:

Problem-solving / Process-improvement tool.

Helps identify points where problems occur.

Steps to Create a Flow Chart:

List steps in the process.

Classify steps as:

Procedure

Decision point

Buffer

Ensure balance—not overly detailed but include key steps.

Flow direction: Usually left-to-right or top-to-bottom.

May utilize "swim-lanes" for different resources.

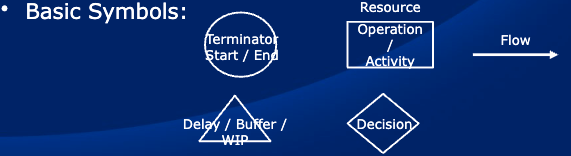

Basic Symbols:

Operation / Activity

Terminator (Start/End)

Delay / Buffer / WIP (Work in Progress)

Decision

Flow

Resource

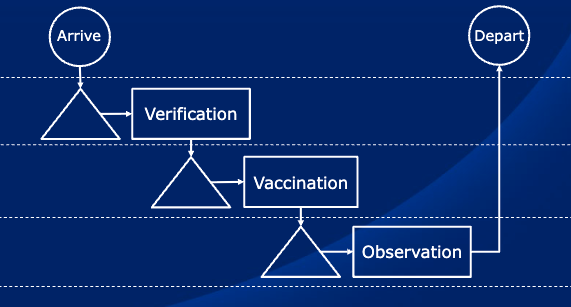

UA Vaccination POD

Value to Customer: Quick & safe service

Process Flow:

Arrive

Verification

Vaccination

Observation

Depart

Job Design

Definition: Specifying the contents and methods of jobs.

Key Considerations:

What will be done in a job?

Who will do the job?

How will the job be done?

Where will the job be done?

Importance:

Organizations depend on human efforts to achieve goals.

Relevant to continuous and productivity improvement.

Objectives of Job Design:

Productivity

Safety

Quality of work life

Efficiency vs. Behavioral Job Design

Efficiency School:

Emphasizes a systematic, logical approach to job design.

Behavioral School:

Emphasizes satisfaction of employee needs and wants.

Primary Issue of Disagreement: Specialization.

Specialization

Definition: Work concentrated on a specific aspect of a product or service.

Advantages for Management:

Simplifies training.

High productivity.

Low wage costs.

Advantages for Employees:

Low education and skill requirements.

Minimum responsibility.

Little mental effort needed.

Disadvantages for Management:

Difficult to motivate quality.

Worker dissatisfaction leads to absenteeism, turnover, disruptive tactics, and poor attention to quality.

Disadvantages for Employees:

Monotonous work.

Limited opportunities for advancement.

Limited control over work.

Little opportunity for self-fulfillment.

Behavioral Approaches to Job Design

Job Enlargement: Giving a worker a larger portion of the total task (horizontal loading).

Job Rotation: Workers periodically exchange jobs.

Job Enrichment: Increasing responsibility for planning and coordination tasks (vertical loading).

Methods Analysis

Definition: Analyzing how a job gets done.

Procedure:

Start with an analysis of the overall operation.

Move from general to specific job details.

Focus Areas:

Workplace arrangement.

Movement of workers and/or materials.

Guidelines for Selecting a Job to Study

Consider jobs that:

Have high labor content.

Are done frequently.

Are unsafe, tiring, unpleasant, or noisy.

Are designated as problems (quality issues, processing bottlenecks, etc.).

Methods Analysis Procedure

Identify the operation to study and gather relevant data.

Discuss the job with the operator and supervisor for input.

Study and document the present methods.

Analyze the job.

Propose new methods.

Install new methods.

Follow up to ensure improvements have been achieved.

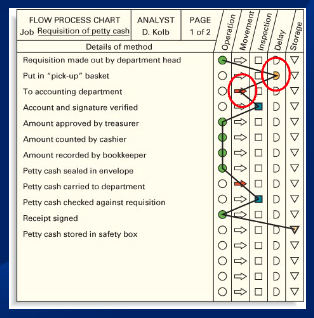

Analyzing the Job Flow Process Charts

Definition: Examine the overall sequence of an operation by focusing on movements of the operator or materials flow.

Purpose: Helps to identify nonproductive parts of the process (delays, temporary storage, unnecessary distance traveled).

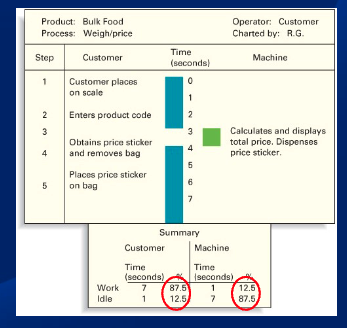

Analyzing the Job Worker-Machine Chart

Definition: Used to determine portions of a work cycle during which an operator and equipment are busy or idle.

Application: Highlights worker & machine utilization (e.g., weighing food in the bulk food section).

Work Measurement

Definition: Concerned with how long it should take to complete a job, not focused on job content or how the job is completed.

Primary Consideration: Job content and methods are assumed to be given in work measurement.

Work Measurement (cont.)

Standard Time: The estimated time it should take a qualified worker to complete a specified task efficiently with a given method, tools, equipment, materials, and layout.

Historical Times

Definition: Standard Elemental Times derived from a firm’s own historical data.

Process:

Accumulate elemental times common to many jobs over time.

Retrieve from the file as needed to avoid performing new time studies.

Predetermined Time Standards

Definition: Use published data on standard elemental times.

Origin: Developed in the 1940s by the Methods Engineering Council.

Application:

MTM tables based on research of basic elemental motions and times.

Analyst divides job into elements (reach, move, turn), measures distances, rates difficulty, and refers to tables for time data.

Work Sampling

Definition: Technique for estimating the proportion of time spent on activities vs. idle time.

Characteristics:

Does not require continuous observation or timing of specific activities.

Involves brief random observations and records activity nature.

Uses:

Ratio-delay studies for worker delays or machine idle time.

Analysis of non-repetitive jobs to understand task time distribution.

Work Sampling Process

Identify the worker or machine to study.

Notify worker and supervisor about study purpose.

Compute initial sample size (n) based on p (set at 0.5 if unknown).

Develop a random observation schedule.

Take observations, adjust sample size if necessary.

Estimate the time proportion spent on specified activities.

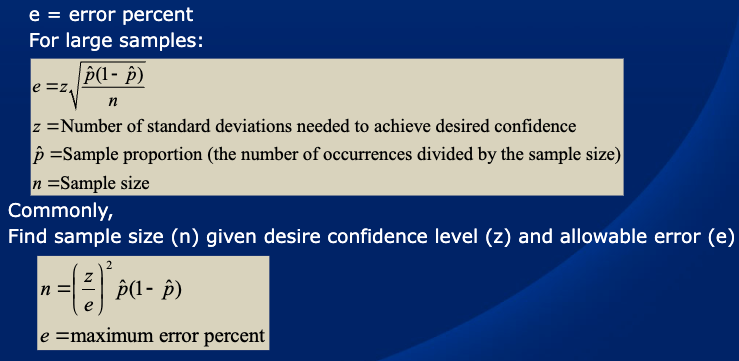

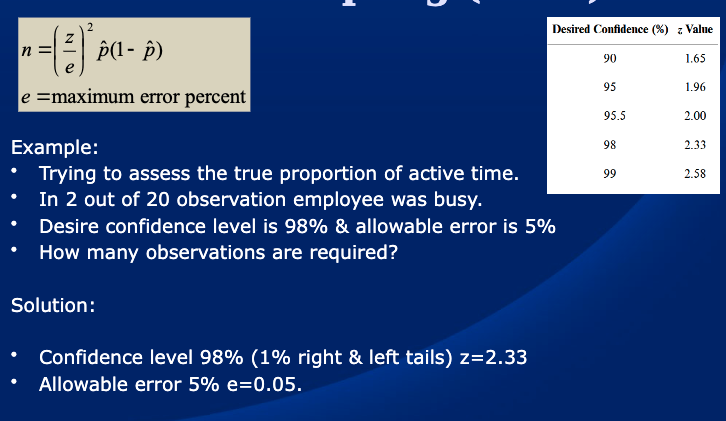

Work Sampling (cont.)

Error percent (e):

Commonly needed when finding sample size.

Example: Assessing active time based on observed proportions.

Factors include confidence level (z value) and allowable error (e).

Stopwatch Time Study

Definition: Develop time standards based on observations of one worker across multiple cycles.

Basic Steps:

Define the task to study and inform the worker.

Determine the number of cycles to observe.

Time the job and rate worker's performance.

Compute standard time.

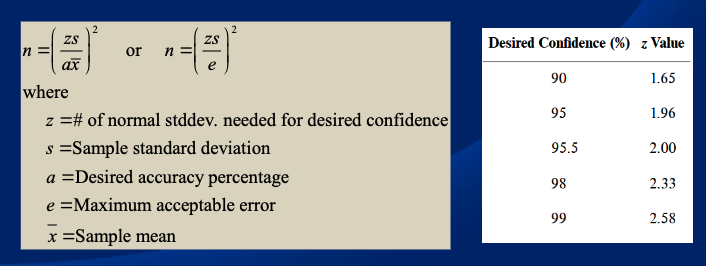

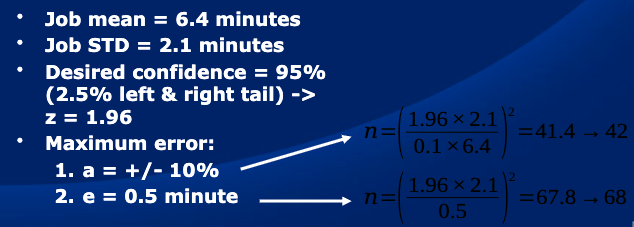

Number of Cycles to Observe

Influencing Factors:

Variability of observed times.

Desired accuracy of results.

Desired confidence level of estimated job time.

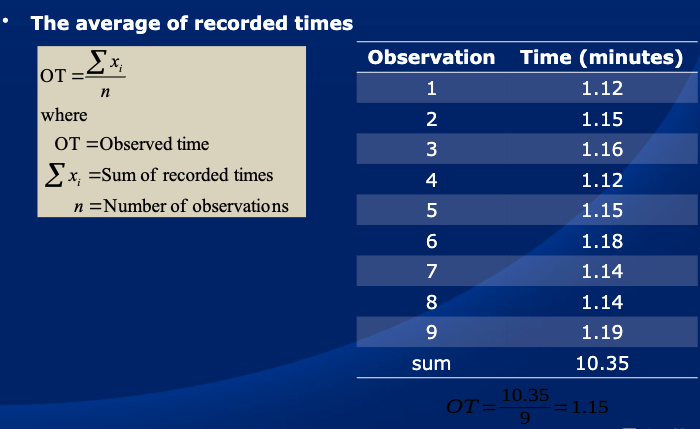

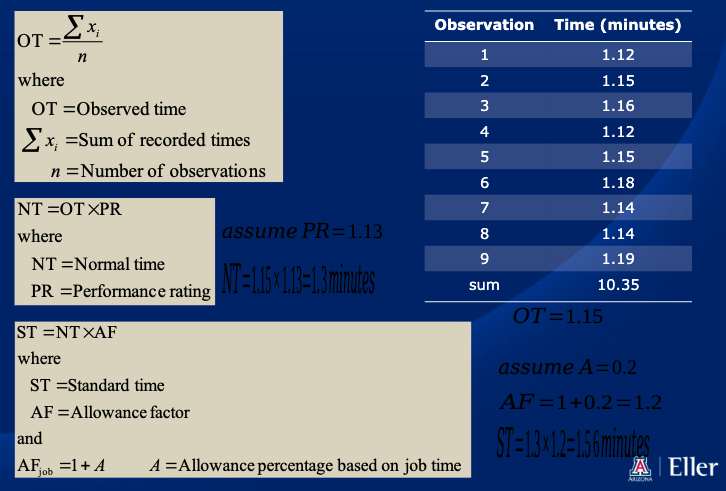

Observed Time

Definition: Average of recorded times during observations.

Example Calculation: Average time = Total observed time / Number of observations.

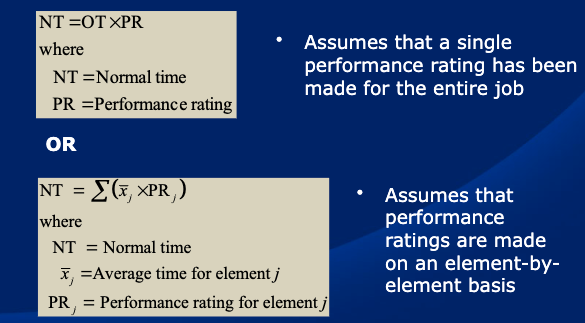

Normal Time

Definition: Adjusted observed time based on performance rating.

Adjustment Factors:

PR > 1: faster than normal performance.

PR < 1: slower than normal performance.

PR = 1: normal pace.

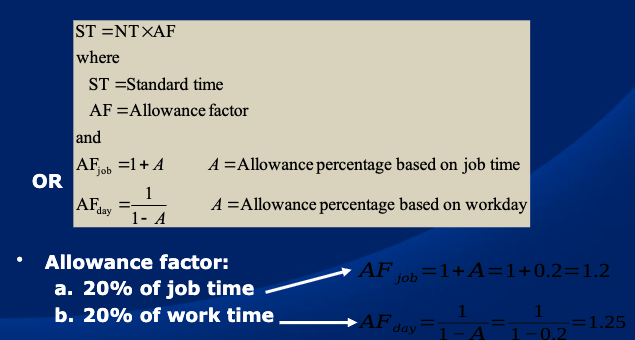

Standard Time

Definition: Normal time adjusted by adding an allowance factor.

Allowance Factors Include:

Personal (fatigue, breaks).

Unavoidable delays (machine adjustments, waiting for materials).

Work Sampling vs. Stopwatch Time Studies

Advantages of Work Sampling:

Reduces short-term fluctuation susceptibility.

Little disruption to work.

Less worker resentment to being observed.

Less costly and time-consuming.

Can be interrupted without result impact.

No timing device necessary.

Effective for non-repetitive tasks.

Disadvantages of Work Sampling:

Reduced detail on job elements.

Potential alteration of work patterns by workers upon spotting an observer.

Often lacks method records by workers.

Random observation schedule adherence issues.

Not suitable for short, repetitive tasks.

Time needed to move between work locations to ensure randomness.