Operations Management

1. Operations Management

Operations Management Defined

Stevenson (2018) defines operations management as the management of systems or

processes that create goods and/or provide services.Operations management is concerned with designing products and services and managing processes and supply chains.

It describes the acquisition, development, and utilization of the resources that firms require to produce and deliver the goods and services that their customers want, and covers strategic and tactical activities and decisions.

Scope

Strategic decisions about the size and location of factories and appropriate supply chains.

Tactical decisions about factory design, project management, and equipment selection.

Operational decisions about production scheduling and quality control.

Operations activities apply in all three economic sectors

the primary sector, e.g. extracting raw materials

secondary sector, e.g. manufacturing, construction, and processing

the tertiary sector, e.g. service provision

Operations management and its relationship with other business functions

Production - is concerned with converting inputs, such as raw materials, into finished products to meet the customers’ needs and wants.

Production will add value, allowing firms to charge a higher price for the finished product than they paid in terms of costs.

Effects of Production on Business Functions

Marketing: the marketing department generates demand and liaises with operations to ensure this quantity can be produced.

Finance: production generates revenue, but it also creates costs that must be paid. Many firms fail because they run out of cash during production.

Human resources management (HRM): the HRM department must guarantee the number of skilled staff required to produce the goods demanded, through appropriate recruiting and training.

2. Producing Goods And Services

Goods vs. Services

The manufacturing-service continuum

According to Krajewski, et al. (2016)., manufacturing processes convert materials into

products, whereas service processes tend to produce intangible, perishable outputs.Oftentimes, companies reside somewhere in between the two ends of the manufacturing-service continuum.

Operations management and economic sustainability

Consisting of three pillars, sustainable development seeks economic, social, and environmental sustainability.

Economic sustainability: the aim of the sustainable economic model is the fair distribution and efficient allocation of resources.

Social sustainability: this aspect supports initiatives like peace, social justice, reducing poverty, and other movements that promote social equity.

Environmental sustainability: this aspect supports initiatives like renewable energy, sustainable agriculture and fishing, organic farming, tree planting, recycling, and better waste management.

3. Operations as a Transformation Process

According to Russell & Taylor (2011), operations are often defined as a transformation process.

Requirements and feedback from customers are used to adjust the many factors involved in the transformation process, which may in turn alter inputs.

In operations management, we try to ensure that the transformation process is performed efficiently and that the output is of greater value than the sum of the inputs.

The role of operations is to create value.

The transformation process can be viewed as a series of activities along a value chain extending from supplier to customer.

Value chain – a series of activities from supplier to customer that add value to a product or service.

Supply Chain

It is a sequence of activities and organizations involved in producing and delivering a good or service.

Two Types of Processes in Supply Chain

Core Processes – a set of activities that deliver external value to customers.

Supplier relationship process — Selects the suppliers of services, materials, and information and facilitates the timely and efficient flow of these items into the firm.

New service/product development process — Designs and develops new services or products from inputs received from external customer specifications or the market in general through the customer relationship process.

Order fulfilment process — Includes the activities required to produce and deliver the service or product to the external customer.

Customer relationship process — Identifies, attracts, and builds relationships with external customers and facilitates the placement of orders by customers, sometimes referred to as customer relationship management.

Support Processes – provide vital resources and inputs to the core processes and are essential to the management of the business. They are found in the other functions of the business: marketing, finance, human resources, and management information systems.

Business Aspects for Management Decisions

According to Heizer & Render (2020), operations managers are mainly concerned with the following:

Design of goods and services

Managing quality

Process and capacity strategy

Location strategy

Layout strategy

Human resources and job design

Supply chain management

Inventory management

Scheduling

Maintenance

4. Current challenges in operations management

Challenges in Operations Management

Globalization

Example: The device you are holding right now is likely designed in

a country different from where it was manufactured.

Supply-chain partnering

Example: The launch of eKadiwa, a Dept. of Agriculture-led digital platform in the Philippines, helped connect farmers, merchants, and consumers during the pandemic.

Sustainability

Example: Adidas X Parley shoes recycled from ocean plastic.

Rapid product development

Example: Nike’s development of medical PPEs during

the pandemic

Mass customization

Example: Nike by You custom shoes

Lean operations

Example: Toyota production system

Steps in analyzing operations management challenges

Identify challenges in the system.

Analyze the challenges of the system.

Generate solutions for the challenges.

Recommend a solution for the challenges.

Adopt the recommended solution.

Maintain the recommended solution.

Re-evaluate the solution.

5. Competitiveness and Strategy

Competitiveness - is how effectively a company meets the wants and needs of customers relative to others that offer similar goods or services.

If you are a business owner, you could also think of it as your ability to be the “first pick” of your customers over your competition.

How do organizations compete?

Stevenson (2018) suggests a few ways you should compete against other businesses. To find success, make sure you are making the most of the following three aspects:

Identifying consumer wants and/or needs — Achieving the perfect match between consumer wants and needs with the organization’s goods and services.

Price and quality — Understanding the trade-off decision consumers make between price and quality.

Advertising and promotion — Using different approaches to inform potential customers of the organization’s goods/services and to attract buyers.

How do organizations use operations management to compete?

According to Stevenson (2018), organizations use the following strategic components to remain competitive:

Product & Service Design

Cost

Location

Quality

Quick Response

Flexibility

Inventory Management

Supply Chain Management

Service

Managers & Workers

Why do some organizations fail?

Operations managers should regularly look at the big picture to prevent any long-term negative impacts on the organization.

According to Stevenson (2018), the reasons why some organizations fail are due to the following:

Neglecting operations strategy

Not taking advantage of strengths and opportunities, and not recognizing competitive threats

Putting too much emphasis on short-term financial goals at the expense of R&D

Placing too much emphasis on product and service design and not enough on process design and improvement

Neglecting investments in capital and human resources

Failing to establish good internal communications and cooperation among different functional areas

Failing to consider consumer wants and needs.

A good operations manager would have to regularly review their performance vis-à-vis:

Organizational mission, goals, strategies

Functional goals

Operations strategies, tactics, and procedures

Hierarchy of Decision-Making Process

6. Mission and Vision Statement

According to Stevenson (2018), an organization’s vision is its reason for existence.

On the other hand, the mission statement states the purpose of the organization.

Goals, Strategies, and Tactics

Goals – provide details and scope of the mission

Strategies – plans for achieving organizational goals. The three basic organizational strategies are:

Low-cost

Responsiveness

Differentiation from other competitors

Tactics – methods and actions taken to accomplish the strategies.

Organizational strategies and corresponding operations strategies

Depending on the strategy of an organization, operations within that organization would have to align themselves accordingly to ensure success amid a competitive business landscape.

The organizational strategy defines the overall direction that an entire organization should take.

On the other hand, operational strategy is much narrower in scope and deals with all

the operations-related activities of the organization.

Effects of Decision Areas on the Aspects of the Firm

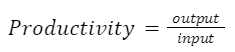

7. Productivity

Productivity – a measure of the effective use of resources, expressed as the ratio of output and input.

![]()

Business leaders are concerned with productivity as it relates to strategies and thus, competitiveness.

Especially useful for businesses that use low-cost as a strategy

Types of Productivity Measures

Partial

Multi-factor

Total

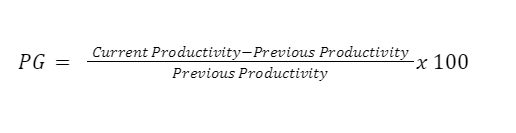

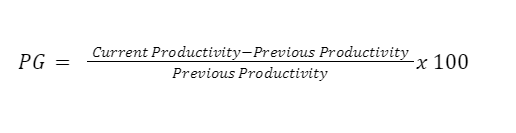

Productivity Growth

8. Product & Service Design

Product Design

Ideas for new products or improvements to existing products can come from various sources such as:

A company’s R&D department

Customer complaints or suggestions

Marketing research

Suppliers

Salespersons in the field

Factory workers

New technological developments

Competitors

Prototyping

Rapid prototyping – is an approach that has emerged in importance over the years due to

shifting customer demands and increasing global competition.

Sequential Design – traditionally approach where companies design products through a linear, department-by-department approach.

Concurrent Design – is a more recent approach popularly used by companies offering digital products, both hardware and software.

Product Design Terminologies

Reverse engineering — carefully dismantling a competitor’s product to improve your product.

Feasibility study — A feasibility study consists of a market analysis, an economic

analysis, and a technical/strategic analysis.Rapid prototyping — creating, testing, and revising a preliminary design model.

Concurrent design — an approach to design that involves the simultaneous design of products and processes by design teams.

Form design — the physical appearance of a product and how the product will work.

Functional design — how the product will perform

Reliability — the probability that a product will perform its intended function for a specified period.

Maintainability (or Serviceability) — refers to the ease and cost with which a product or service is maintained or repaired.

Usability — ease of use of a product or service.

Production design — how the product will be made.

Final design — detailed drawings and specifications for the new product or service

Process plans — workable instructions for manufacture, including necessary equipment and tooling, component sourcing recommendations, job descriptions and procedures for workers, and computer programs for automated machines.

Service Design

One of the reasons why a business may fail is the assumption that focusing on the manufacturing and shipping of a product alone would be enough to bring in customers and revenue.

According to Russell & Taylor (2011), a lack of effort in intentionally designing services would rarely meet customer needs.

Service Design Terminologies

Service concept — defines the target customer and the desired customer experience. It also defines how our service differs from others and how it will compete in the marketplace.

Service package — created to meet customer needs and consists of physical items, sensual benefits, and psychological benefits.

Performance specifications — outline expectations and requirements

Design specifications — describe the service in enough detail to be replicated.

Delivery specifications — specify schedules, deliverables, and location.

9. Capacity Planning

Capacity - is the maximum output rate of a process or a system.

Managers are responsible for ensuring that the firm can meet current and future demand.

Adjusting to decrease capacity or to overcome capacity shortfalls is an important job of managers.

Key Questions in Capacity Planning

What kind of capacity is needed?

How much is needed to match demand?

When is it needed?

Types of Capacity

Design capacity - the maximum output rate or service capacity an operation or facility is designed for.

Effective capacity - is the design capacity minus allowances such as personal time, equipment maintenance, delays, and changing the product mix.

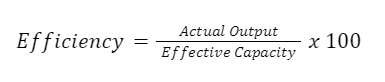

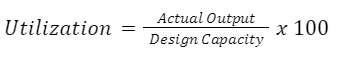

Measures of Capacity

Efficiency Rate

Utilization Rate

Steps in the capacity planning process

Stevenson (2018) offers a generic list of the capacity planning process. The actual steps involved vary depending on the business and the industry:

Estimate future capacity requirements.

Evaluate existing capacity and facilities and identify gaps.

Identify alternatives.

Conduct a financial analysis of each alternative

Assess key qualitative issues of each alternative.

Select the alternative that will bring the best long-term outcome.

Implement the selected alternative.

Monitor results

10. Process Selection

Process selection — deciding on the way the production of goods or services will be organized

Has major implications for capacity planning, layout of facilities, equipment, and design of work systems.

Always done when new products or services are being planned

Sometimes done because of:Technological changes in products or equipment

Competitive pressures

Characteristics of Process Selection

Process selection is based on process strategy

Process selection is demand-driven

Questions for an Operations Manager

How much variety in products/services will the system need to handle?

What degree of equipment flexibility will be needed?

What is the expected volume of output?

Capital & Process

Capital intensity — the mix of equipment and labor that will be used by the

organization

Process flexibility — the degree to which the system can be adjusted to changes in

process requirements. Some examples of such changes are:

Changes in product and service design

Changes in volume processed

Changes in technology

Process Types

Job Shop

Used when a low volume of high-variety goods or services will be needed.

Work includes small jobs, each with somewhat different requirements.

High skill level of workers

Batch

Used when a moderate volume of goods or services is desired with a moderate variety in products/services.

Equipment need not be as flexible.

Lower skill level of workers than job shop

Repetitive

Used when higher volumes of more standardized goods/services are needed.

Only needs slight flexibility of equipment.

Low skill level of workers a.k.a., assembly

Continuous

Used when a very high volume of non-discrete, highly standardized output is desired.

Almost no variety in output; thus, no need for equipment flexibility

Workers’ skill requirements range from low to high, depending on the expertise needed and system complexity.

Project

Used for non-routine work, with a unique set of objectives to be accomplished in a limited time frame.

Equipment flexibility and worker skills range from low to high.

Identifying value-adding and cost-adding processes

Value – the amount customers are willing to pay for what an organization provides.

Benefits can be informational, emotional, and economic. It is also the quality received relative to expectations.

Value-adding – a positive contribution that a process makes to the final usefulness or value of a product.

Cost-adding – a negative contribution that a process makes to the final usefulness or value of a product.

Primary process – performs the main value-added activities of an organization.

Secondary process – creates value for the internal customer (i.e., from within the

organization)

Value- & Cost-Adding Processes

According to Gardiner & Reefke (2020), a process is either value-adding or cost-adding— they are mutually exclusive. Although all customers want value, it is not easy to define.

There is no quantitative measure for value because it includes both tangibles and intangibles.

Value-adding or primary processes create value for and directly interact with the external customer.

On the other hand, secondary processes create value for the internal customer and are important for the smooth running of the organization.

It should be noted that the external customer usually will not place any value on these secondary processes.

Examples of Secondary Processes

Hiring and terminating employees

Checking the credit rating of new customers

Closing accounting activities without disrupting the normal operations of the organization

Researching and developing new products and services

Identifying new suppliers and sources of materials

The Perfect Process

James Womack (2003) described the perfect process as one that creates the right value for the customer, whether external or internal to the organization. Each primary and secondary process must be valuable, capable, available, adequate, and flexible:

Valuable – adds value to the customer; value-adding and not cost-adding

Capable – executes the same way with the same satisfactory result every time

Available – available for use and not waiting for repair or maintenance

Adequate – has enough capacity to perform when required without waiting

Flexible – responds quickly and easily to predicted and unpredicted changes