17 Carbonates

Calcium Oxide and Calcium Carbonate

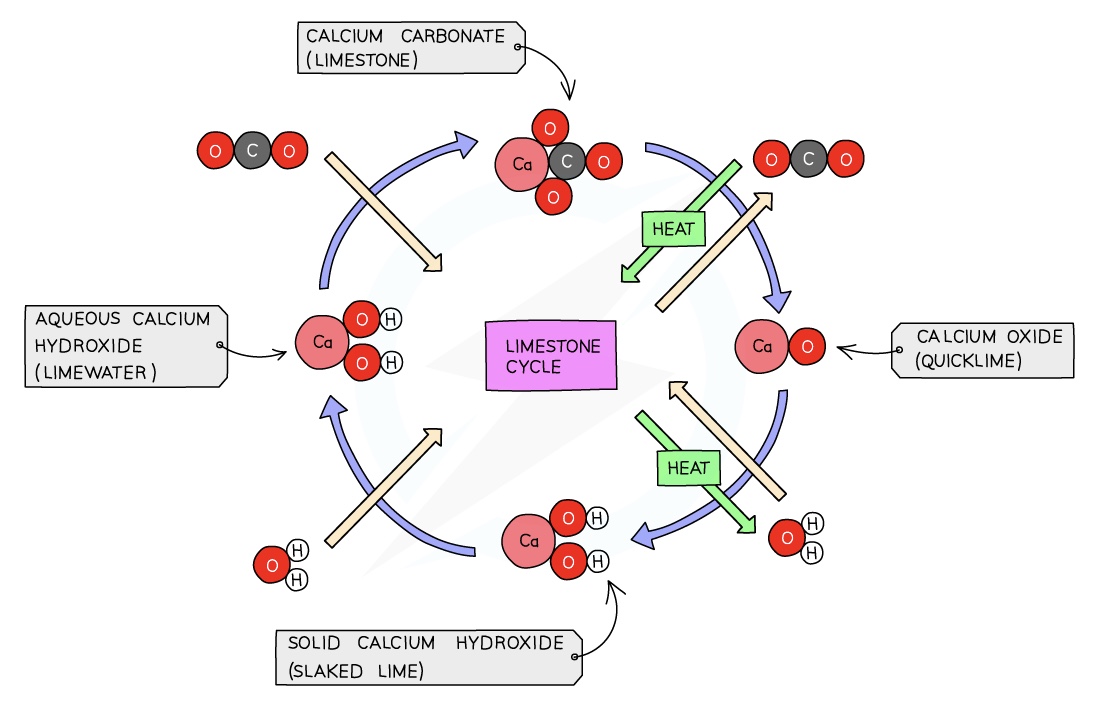

Limestone consists mainly of calcium carbonate, CaCO3

Lime which is calcium oxide, CaO, is manufactured from calcium carbonate by thermal decomposition:

- CaCO3 → CaO + CO2

Slaked lime, calcium hydroxide, Ca(OH)2, is made by adding a small amount of water slowly to calcium oxide:

- CaO+ H2O → Ca(OH)2

The water is added slowly because the reaction is quite exothermic

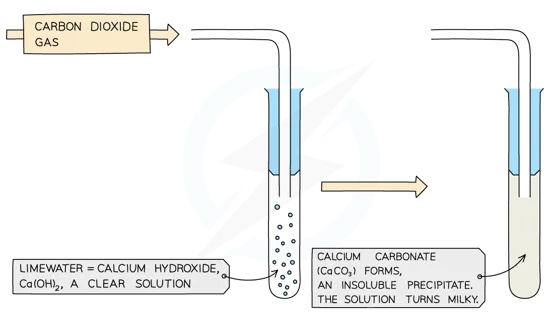

Limewater is a solution of calcium hydroxide in water, hence it is weakly alkaline

Bubbling carbon dioxide through limewater produces a cloudy white precipitate of calcium carbonate, so the sequence of reactions has gone in a complete cycle, returning to the starting material:

- CO2 + Ca(OH)2 → CaCO3 + H20

This reaction is the basis of the standard chemical test for CO2

The combination of these three reactions constitute the limestone cycle

Use of limestone and limestone products

Limestone (calcium carbonate) is used in the manufacture of iron and cement

In the production of iron, limestone is added to the blast furnace where it decomposes to form lime (CaO) and carbon dioxide

The CO2 produced is reduced to carbon monoxide, CO, by coke (almost pure carbon) where it acts as a reducing agent transforming iron ore into iron:

CO2 + C → 2CO

Fe2O3 + 3CO → 2Fe + 3CO2

The lime reacts with silica impurities in the iron ore to form calcium silicate, which floats to the top of the molten iron as slag and is removed:

- CaO + SiO2 CaSiO3

Cement is manufactured by heating a mixture of powdered limestone and clay in a rotary kiln

Once heated, calcium sulfate and water are added which produce cement

Cement is a hardened, interlocked structure of calcium aluminate (Ca(AlO2)2 and calcium silicate (CaSiO3)

@@CaCO3 is also used in treating excess acidity in@@ soils and lakes where it is often preferred to lime because it does not make the water excessively alkaline

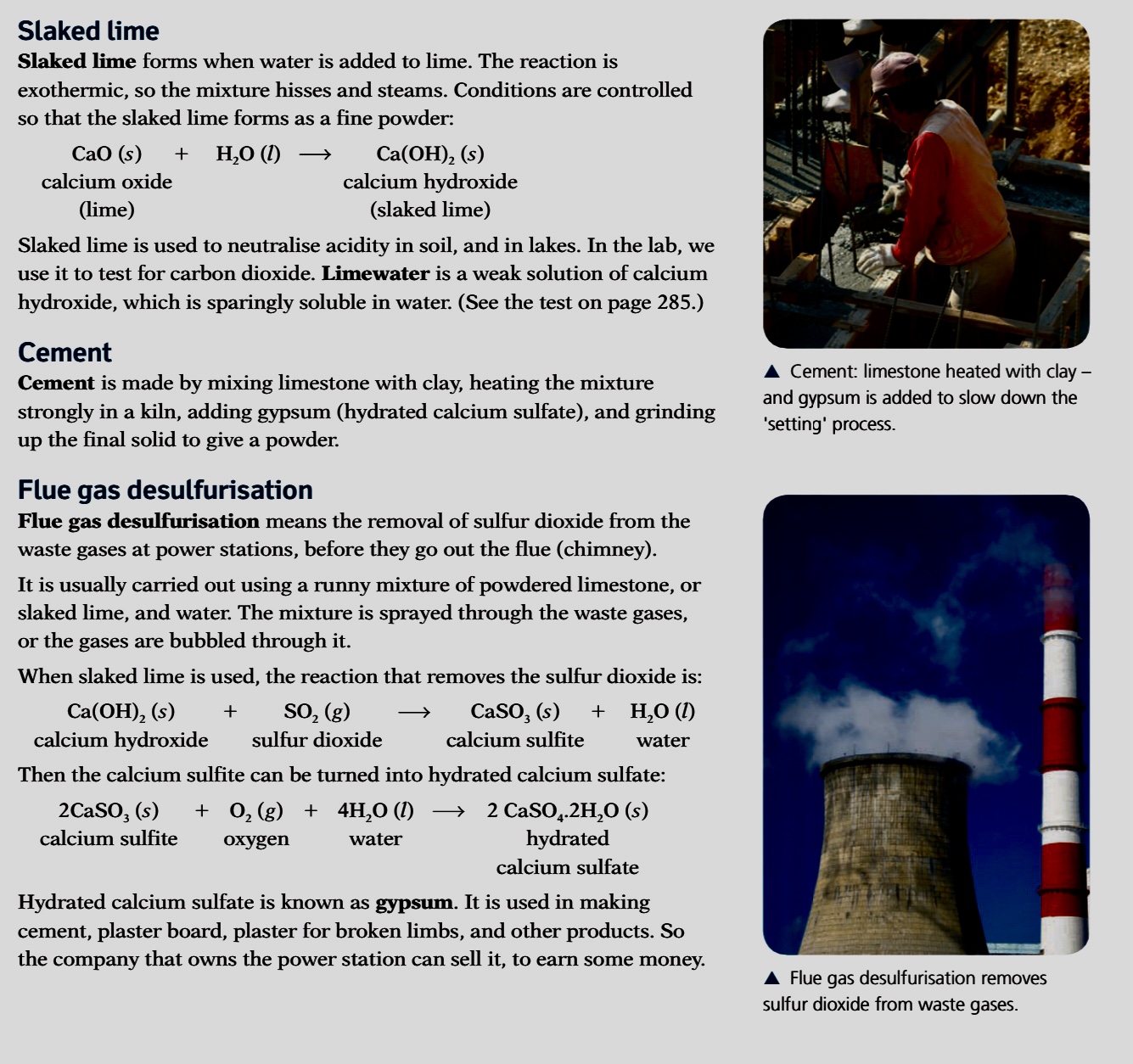

@@Lime (calcium oxide) is used in lime mortar, the material used to bind bricks together, and in flue-gas desulphurisation@@

Flue-gas desulphurisation involves spraying jets of slaked lime slurry into acidic sulfur dioxide emissions to reduce pollution by neutralising these gases before they leave the factory chimneys

Slaked lime (calcium hydroxide) is used in treating acidic soils and neutralising acidic industrial wasted products

\n \n