DT REVISION

COMPOSITE MATERIALS:

STRAW AND MUD BRICKS

the mud provides the compression and the straw provides the tension. the straw is mixed with mud to stop it cracking when it dries. they bind together to form strong bricks that shouldn't break/crack.

THE REINFORCED CONCRETE BRIDGE

the bridge is made from reinforced concrete. this is a normal concrete bridge however it has steal rods through it to stop the bridge collapsing so quickly. concrete is strong when under compressive force e.g buildings. however concrete is very weak when under tension. e.g bridges so that’s why steal rods are instuled to keep it sturdy.

A YACHT WITH GRP HULL

GRP is glass reinforced polymer. this is made from fibre glass which is composed into a mould with polymer resin. you repeat this several times which then results in material which is strong and light. it has a high strength to weight ratio making it useful for the production of products e.g. boat hulls.

A CARBON FIBRE FORMULA 1 CAR

CFRP is carbon fibre reinforced polymer (plastic which is similar to fibre glass) carbon fibre is woven into textile material and resin is applied into the layers. although its much more expensive, it is an improvement on glass fibre than reinforced plastic. its tend to be used when making sports cars because they are light and strong.

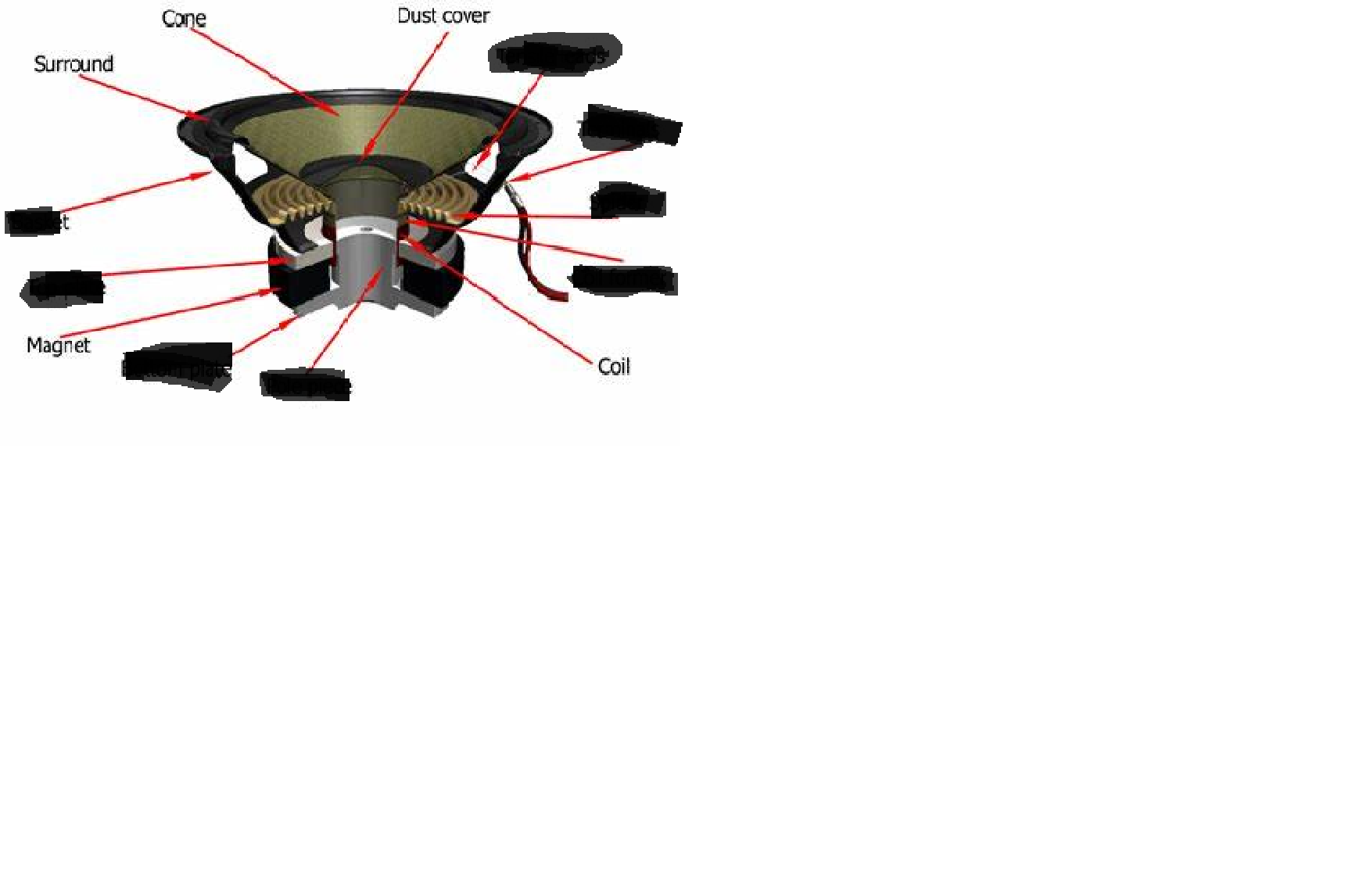

PARTS OF THE SPEAKER:

need to know;

frame

dust cap/cover

copper voice coil/electromagnet

permanent magnet

power supply

rubber surround electro

paper diaphragm/cone

COMPONENTS AND THEIR JOBS:

fixed resistors: resist the current flowing in the circuit, limiting the amount flowing through certain components, measured in ohms

ceramic disc capacitors: store electrical charge. they instantly charge when connected to a power source then slowly discharge their current, measured in farads.

electrolytic capacitor: same as ceramic disc capacitors. some capacitors are connected across the supply legs of the audio amplifier chip to make sure it remans stable.

jack lead and connector: connects the audio input to the PCB, so that the signal from the audio input can be amplified.

LED: to signify that there is power the PCB, a special type of diode,

this semi-conductor glows when a current is passed through it.

single pole single throw / on/off switch: to turn the circuit on and off. this type of switch is know as SPST latching switch.

9V battery: self contained power source that powers the circuit - converts chemical energy into electrical energy. connected using battery snap.

speaker: provides sound. the diaphragm compresses the air particles in front of it. how it does this is determined by the audio input.

audio amplifier integrated circuit chip: contains transistors. these amplify a small input signal into a more powerful output signal to drive the speaker.

INPUT PROCESS: one that sets an electrical circuit in action. it requires another stimulus in order to function. e.g switch

PROCESS: a component that sits within an electrical circuit and does something. e.g. resistor

OUTPUT PROCESS: what results from an electrical circuit. e.g. motor

successful soldering:

plug in the soldering iron and allow it to cool up. ensure you are wearing googles and your work area is well ventilated.

set up the rest of your equipment; heat proof mat, flux, and wire cutters ect ready

push your component through the component side and then bend the component legs down onto the track side.

place the soldering iron onto the pad a few degrees off flat and hold it for around 3 seconds.

then add the flux to the bottom of the soldering iron and hold it there for 5 seconds.

keep pushing the wire into the soldering iron as its melting until a volcano like shape forms.

once a volcano forms, place the soldering iron in the soldering iron holder.

use the wire cutters to trim off the excess wire and remove any excess solder on the wet sponge and then repeat the steps with the other components.

dry joint:

a dry joint is when the solder has a bad connection so it occurs when the cooling solder moves. the causes are that it could give equipment a problem that’s hard to solve as well as electricity not able to flow.

polarised:

it means it can only be connected to a circuit in one direction. e.g. positive and negative side/will only work one way.

manufacturing your amplifier pine box:

we marked out our 1m length of pine into 4 sections. my wood was 150mm by 200mm.

we marked out 5 finger joints (18.5mm x 15mm) on either end of each section of wood.

we then cut 1m length of wood in the middle of the marked finger joints.

we cut vertically down each finger joint to the shoulder line and cut off the shaded corners.

then we cut out out the shaded internal finger joints by using a coping saw.

tools and machines:

tenon saw

steel rule

try square

sharp pencil

bench hook

clamp

vice

scroll saw

coping saw

pillar drill with a hole saw

health and safety:

make sure not to blow saw dust, it might get in your eyes

make sure not to get splinter from the wood

try not to cut yourself, swing a saw around/be careful around others

be careful of cutting others of yourself, don’t pinch yourself in the vice.

make sure to turn the machine off, don’t cut yourself.

wear googles and an apron

make sure to tie your hair back.