3D Final

1/24

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

25 Terms

Larger Nozzles (>0.4 mm)

Smaller Nozzles (<0.4 mm)

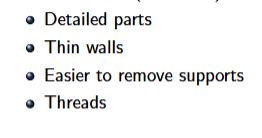

Types of 3D Printers

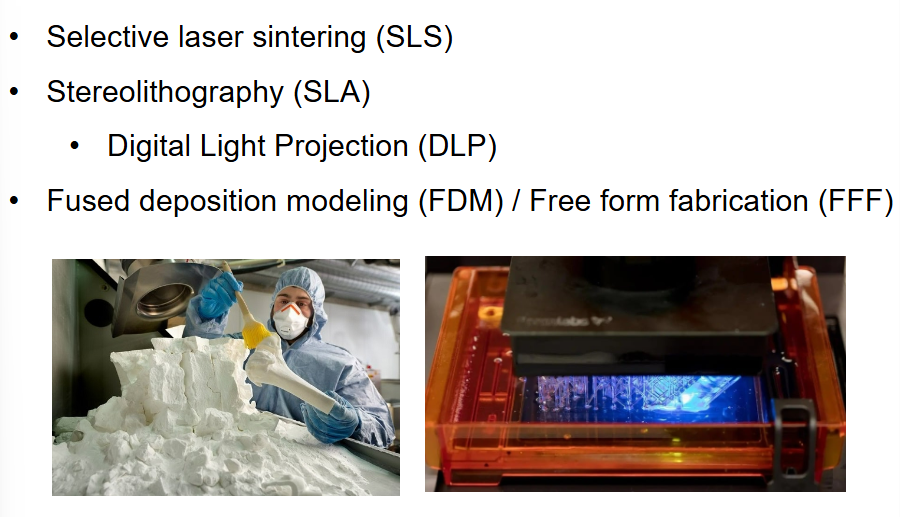

Selective Laser Sintering (SLS)

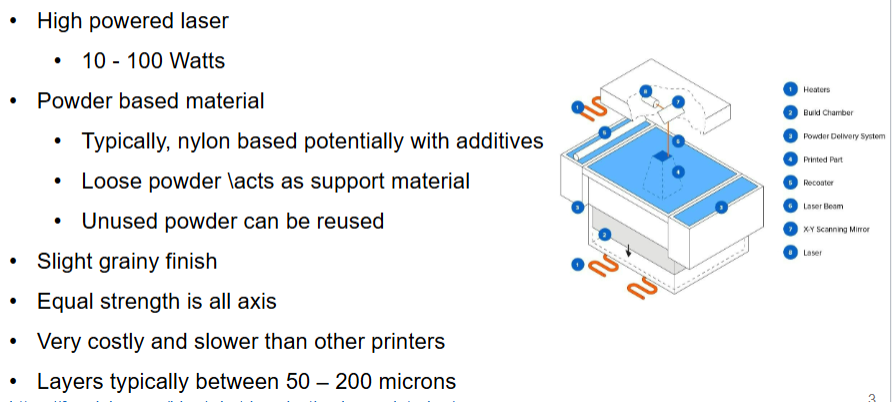

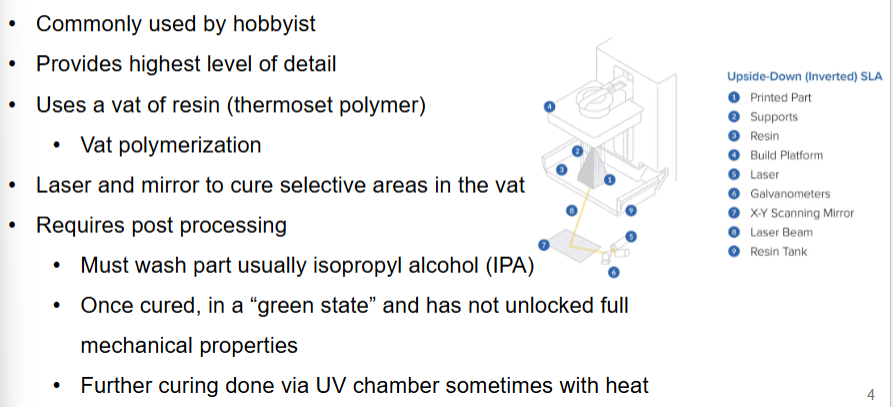

Stereolithography(SLA)

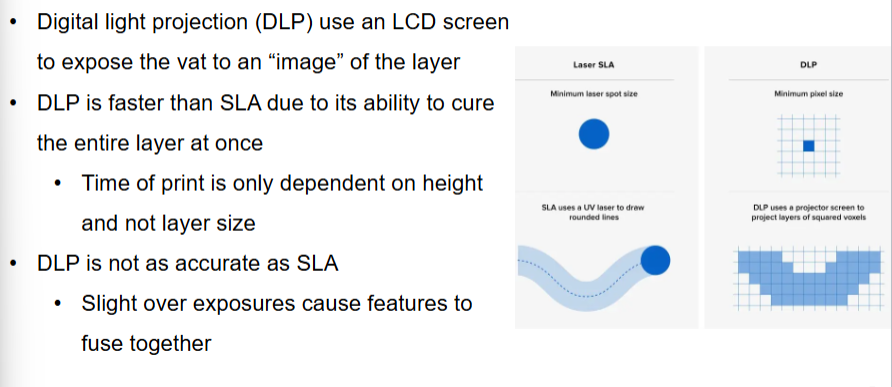

Digital Light Projection (DLP)

Can print many instances because entire layer is printed at once

Free Form Fabrication (FFF)

Bed Slinger(Ones we use in Lab) and Core XY(Door Closes) model

Saftey Concerns for SLS

When post processing, need mask to prevent inhalation of fine dust

SLA

Resin can be toxic and an irritant, always wear gloves when handing uncured resin and IPA. Additives such as fiber glass can splinter into your hand. Good ventilation for fumes.

FFF

Good ventilation if fumes are being released. Nozzle heats to high temperatures.

PLA Material (Polylactic Acid)

PETG Material (Polyethylene terephthalate glycol)

TPU Material (Thermoplastic Polyurethane)

ABS material (Acrylonitrile Butadiene Styrene)

What is the Purpose of A Benchy

The purpose of a ———- is to act as a comprehensive diagnostic and calibration tool for 3D printers

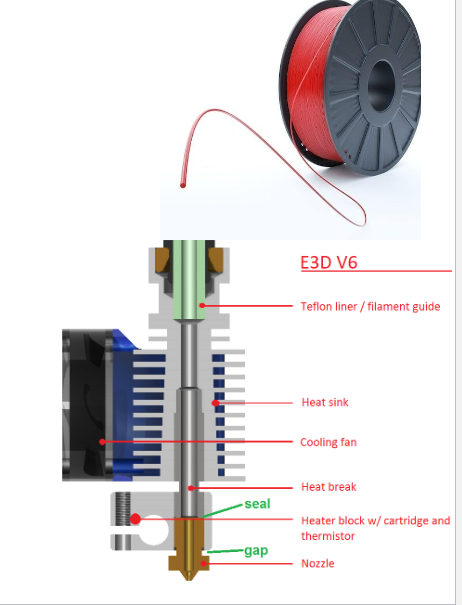

Hotend Structure

In what ways resin is used differently than regular filament

Resin printing is cured by a light source (SLA/DLP/LCD) layer by layer

.stl

The 3D model you start with

.sls1

A specific file type for a resin printer

G-CODE

A sliced file for a specific FDM/FFF printer

How Files work together

.stl is the first stop for your model(prusaslicer model) then it is converted into a file depending on your printer. If it is a FDM/FFF it will need to be g-code. If it is SLA/DLP it will need to be sls1. For SLS the most typical is just .stl or the more modern .3MF.

DLP Vs SLA

SLA is a laser based device printer. Both of these are based on light to cure resin. DLP is different in the way it prints. It is light focused aswell but is across a wide bed that prints each layer at the same speed. So you can print a lot at once.

Prusaslicer Vs CAD

Prusaslicer Is not for creating new complete items. In analogy form: Prusa is putting the pieces of a car together while CAD Is building the individual pieces.

Layer Shifts

Occurs when the layers of a print are misaligned, causing the object to appear skewed or “stepped” in one or more directions. Caused by glitches, motor issues, High print speed. General Reduction if you choose a lower print speed and acceleration.

PETG vs PLA

PLA is brittle and weaker overall but easier to use for hobbyists. PETG is stronger, More durable and softens at a higher temp. But the tradeoff is PETG is usually harder to print(HIGHER NOZZLE TEMP) and requires more fine tunning.