ch. 4/5 - electromagnetism and the x-ray tube

1/74

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

75 Terms

Magnetism

• The force exerted by a magnet when they attract or repel each other

Fundamental force (or force of nature)

Results from the motion of a charged atomic particle

magnet

object with a magnetic field

any charged object in motion has a magnetic field

orbital magnetic moment

anything moving point A to point B has a circular field of magnetism

Spin magnetic moment

moves around and around in a circle (spins on axis)

Magnetic dipoles

has a north and South Pole

magnetic domains

collection of dipoles put together.

the more dipoles put together, the stronger it it

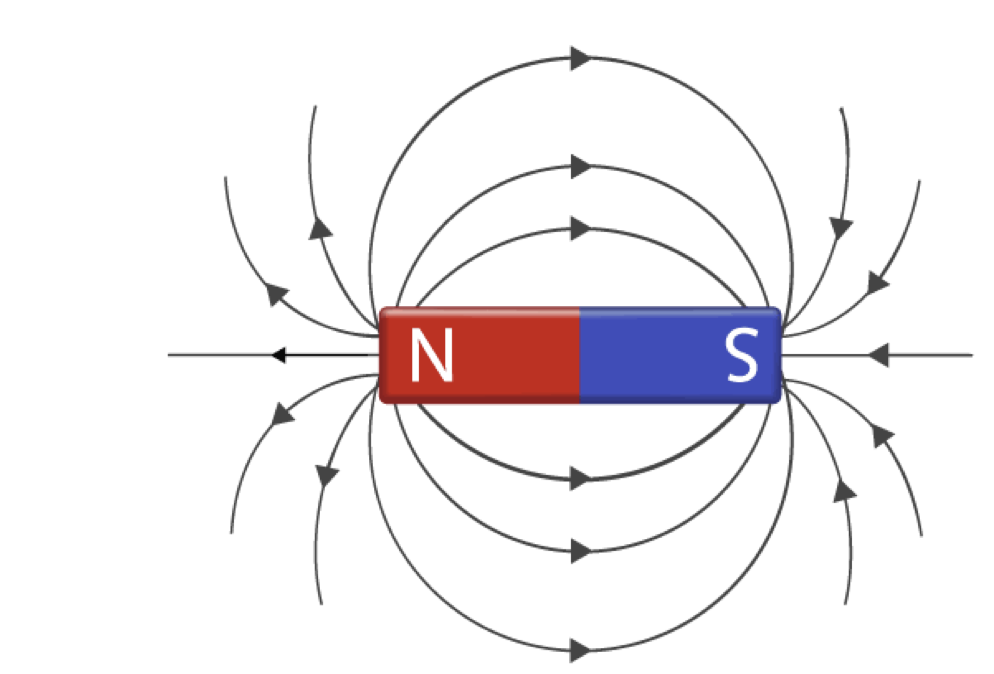

Lines of force (Lines of flux)

the lines around a dipole. stronger=more lines

measured in Wb

magnetic flux=

number of lines of flux in Wb

field strength/area

flux density

strength of magnet (more lines=more density= more strength)

Direction of flow

direction of lines of flux

Outside magnet

Inside magnet

Lines of force NEVER intersect

Forms a 3-dimensional force field around and through magnetic material

earth’s magnetism

The earth is a magnet

A compass will align itself with the earth’s magnetic lines of force and indicate direction

Both north and south poles tend to drift

Classifications of Magnets

natural permanent, artificial permanent, electromagnets

Natural permanent magnet

when iron oxide orients and creates a natural magnet

ex. Lodestones

artificial permanent magnet

man made

Alnico

- Aluminum, nickel, cobalt

Electromagnets

Temporary due to moving electric current

When the current stops flowing, the magnetic field collapses

Laws of Magnetism

repulsion-attraction

inverse square law

magnets demonstrate polarity

repulsion-attraction

like poles attract

opposite poles attract

true for dipoles and lines of force

inverse square law

Force between two magnetic fields directly proportional to product of their magnitudes and

inversely proportional to square of distance between them

as it gets further away, intensity of magnetic fields decreases

I1/I2 = D2 ² / D1 ²

Magnets demonstrate polarity

• Magnetic poles

Regions of magnetism always exist as a dipole (N, S)

• No matter how small it gets

Inverse square law applies to:

Magnetism

Electric field

Gravity

Oersted’s experiment

Demonstrated a relationship between a moving electric charge and magnetism

Charge in motion will create magnetic field

Magnetic field is always perpendicular to direction of moving charge

Fleming’s Hand Rules

• Helps to remember the relationship between electricity and magnetism

- Hand thumb rules along conductor

- Hand thumb rules for solenoid

Fleming’s Right Hand Thumb Rule for a Straight conductor

• Hold a solid conductor in right hand

Wrap fingers around conductor with thumb placed adjacent to wire

• Right-hand thumb rule

Thumb indicates direction of current (conventional flow, positive to negative)

Fingers indicate direction of magnetic field surrounding electrical conducting wire

Related to Lenz’s law

Solenoid

(type of electromagnet)

A coiled, helix of wire carrying an electrical current

strength of electromagnet depends on the amount of coils

detent=lock in the ceiling, type of electromagnet/solenoid. locks x-ray tube at a specific distance for proper SID

Two Primary Laws of Electromagnetics

• Both laws govern the induction of current by magnetic fields

• Faraday’s Law

First law of electromagnetics

• Lenz’s Law

Second law of electromagnetics

Three ways to create motion between lines of force and a conductor (to create an electric current)

Move the conductor

Move the magnetic lines of force

Vary the magnetic flux (objects are stationary, but field is moving)

Four Factors of Faraday’s Law

These four factors regulate the strength of induced current when magnetic lines of force and a conductor are in motion relative to one another:

if these factors are increased, strength of current increases (directly related)

1. Strength of magnetic field

2. Speed of motion between lines of force and conductor

3. Angle between lines of flux and conductor (increase or decrease area)

4. Number of turns in conductor coil

Lenz’s Law

• Applied Faraday’s law to his new discovery

• Induced current flow creates a magnetic field opposing the action that produced the original current

if you induce a new current, they will oppose each other since you can’t create new energy (one goes up, the other goes down)

Self-Induction

• Single coil

• Always present in coils supplied with alternating current

• Constantly changing current polarity (+)(-) or (-) (+)

Changing magnetic field

Induces voltage opposing original current

Inductive reactance

The tendency of alternating current to exist

Dependent on current supplied to the coil

Mutual Induction

• Two coils brought close together, one has a charge, other doesn’t. Creates a charge in the other

• Varying current supplied to primary coil and therefore varying EMF

• Induces current in secondary coil

• Two coils are electrically insulated from each other

supplied by AC (alternating current)

Generators

• Convert mechanical energy to electrical energy

• Can produce direct current or alternating current

• Components:

o Armature (coil of wire)

o Magnets

o Slip rings

o Brushes

Motors

• Convert electrical to mechanical energy

• Similar components to generators

• Armature supplied with current

Devices Controlling Electrical Current

• Transformers

• Autotransformers

• Capacitors

• Note:

These three devices are now miniaturized in chip technology!

Transformers

• Work on principle of mutual induction and Ohm’s law (V=IR)

• AC current

Electrons move in one direction and reverse

Allows variation of voltage levels

All electric power is transmitted this way from generating facilities to end users

• Two coils

Current supplied to primary coil

Induced voltage on secondary coil

Coils are electrically isolated from each other

Step-up transformer

voltage is increased from primary coil to secondary coil

step-down transformer

Voltage is decreased from primary coil to secondary coil

Transformer Types that use Mutual Induction

• Air Core

two coils close to each other

• Open Core

primary and secondary coil are filled with an iron core

• Closed Core

has iron enclosed in top and bottom

• Shell type

Most efficient

Most common

Used by X-ray generators

two closed core together

Autotransformers (Variable Transformers)

• Two designs:

Primary and secondary coils connected in series (instead of insulating them like we saw with mutual induction)

Single coil on central core

Both are considered self induction

• Primary side is supplied with varying current

• Used to select kVp of x-ray exposure

Basic X-Ray Circuit

Divided into three divisions:

1. Low voltage circuit (main circuit)

2. High voltage circuit (main circuit)

->AKA high tension circuit

3. Filament circuit

Capacitors

• Accumulates and stores electrical charge/energy

• Charged with direct current (DC) voltage

Electrons move in one direction only in a direct stream

• Simple design

• Useful in mobile xray units for small body parts

Can’t handle thick body parts due to voltage drop

Rectification

Process of changing AC to DC

• Half-wave rectification (suppresses/ignores half of the current)

• Full-wave rectification

• Located in high voltage section

Rectifiers

Solid-state diodes

Vacuum-tube rectifier

• Considered obsolete

Solid-State Diodes

Rectifier used in x-ray machines

• Solid state design acts like a “one-way gate” (direct current)

• Uses p-n junction semiconductors

n-type material (loosely bound electrons relatively free to move)

p-type material (holes or spaces where there are no electrons)

Electrons flow from the n side (-) to the p side (+)

Need for Rectification in X-Ray Circuits

• X-ray tubes require D C

• Rectification ensures only D C is applied to x-ray tube with 4 solid state diodes (full wave rectification)

Electrons travel from cathode (-) to anode (+)

• Current passing from anode to cathode is very damaging to x-ray tube because it would create way too much heat!

• The way the x-ray circuit is built protects from current that can damage the equipment

Thermionic Emission

• Electrical process of liberating electrons from a wire filament

• Filament is heated to very high temperature due to creating resistance with it’s small diameter

Filament is typically tungsten

• “Boiling off” electrons create an electron cloud around filament

• Principle of an incandescent light bulb

• Very important to x-ray tube design

4 Conditions for the Production of X-Rays

1. Source of electrons

come from the Cathode filament

2. Target

Tungsten anode

3. High-voltage (kVp)

4. Vacuum

X-ray tubes work on the principle of electrons flowing through a vacuum

Cathode Assembly

• Filament

Coiled tungsten wire helix

• Focusing cup

• Associated wiring

Low voltage side of x-ray circuit

Source of electrons

3 main functions of the cathode (-)

produce a thermionic (electron) cloud (main function)

increase kVp

focus/direct electrons toward the target

Filament

• Dual Focus

• Thermionic emission

• Coil of thoriated tungsten (thorium makes it a better conductor)

0.1–0.2 millimeter (mm) thick

1–2 mm wide

7–15 mm long

• Tungsten used because of high melting point

3,370°C

tiny, electrons have trouble getting through so creates high heat

Thermionic Emission

• Electrical process of liberating electrons from a wire filament

• Filament is heated to very high temperature due to creating resistance with it’s small diameter

Filament is typically tungsten

• “Boiling off” electrons create an electron cloud around filament

• Principle of an incandescent light bulb

• Very important to x-ray tube design

Focusing Cup

points in the direction of target, has a small filament to allow electrons out, focusing them

• Composed of nickel

• Low negative potential applied

• Compresses or narrows thermionic cloud

“space charge”

• Space charge effect

Congested electrons limiting current flow

Limits exposure milliamperes (mA) to 1000–1200

electron cloud is sitting, more electrons are piling, potential charge grows, low kVp

• Saturation current

Typically controlled by x-ray circuitry (kVp)

Higher kVp gives a bigger push of electrons towards to the anode

Eliminates the space charge effect

when we use kVp/exposure to move electrons

mAs

miliamperes-second

# electrons (intensity)

current

kVp

kilovoltage peak

strength of beam

penetrability

Grid-Biased Tubes

• Precise control of thermionic cloud (exposure)

• Briefly changes charge of focusing cup from negative to positive

Attracts electrons and stops electron flow

• Permits very short, rapid sequencing of exposures

Starting and stopping the xray beam over and over

• Commonly used in:

Angiography

Pulsed fluoroscopy

Tube Failure (Cathode)

• Tube arcing

Vaporized tungsten collection on envelope because it gets so hot (metal envelope collects less than glass)

• Filament breakage

“Boost” and hold (push all the way down) vs repeated tube “boosting” (push exposure button down halfway first)

Filaments become increasingly thin due to vaporization over time (too much heat)

Most modern x-ray tubes will last between 10,000-20,000 exposures

Anode Assembly

• Three components:

• Anode (with target) (focal track target)

• Stator

• Rotor

Anode Assembly

• Three functions:

• Target surface for x-ray production

• Conducts high voltage (recycles energy from cathode back to generator)

Maintains a closed-circuit pathway

• Serves as primary thermal conductor

Stationary Anode

Only used for low energy x-ray machines such as dental units

Rotating Anode

• Modern x-ray machines

constantly turn during exposure, creates a larger target

• Made of Tungsten–rhenium alloy

• High atomic number

Z# 74

Excellent for x-ray production

• High melting point

• Heat-conducting ability

Stator

• Wraps around the rotor outside the envelope

• Electromagnets consisting of copper windings

• Stator failure

Results in suboptimal anode rotation speed (rotor stops turning)

Immediate melting on target results from too much heat (bullet melt)

Rotor

• Ferromagnetic bars arranged in cylindrical pattern

• Inside stator and envelope

• Copper cylinder connected to anode disk by molybdenum stem

• Turns when stator is energized

Rotation speeds 3,000-12,000 r p m

• Ball bearings

Located inside the rotor

Silver plated

Reduces surface contact & friction

Tube Failure (Anode)

• Ball bearings worn by long use at high temperature

• Melting of the anode disk due to overheating

AKA rotor failure!

Stator fails and rotor ceases to turn

• Causes:

Overload

Poor power conditions

Mechanical failure

Target Area

• Portion of anode that electron stream contacts

on an angle of 12 degrees

made of tungsten

• Referred to by several names

Target

Focus

Focal point

Focal spot (actual)

Focal track

• Point source of x-ray photons

• This is where they are created!

4 required things for x-ray production

• A source of electrons through thermionic emission

• A means of accelerating the electrons (kVp)

• A means of decelerating the electrons (target)

vacuum

Actual focal spot

• Physical area where the electrons strike on the target

• Controlled by length of filament & target angle

• Small actual focal spot is mA limited (only so many electrons can strike because of how big it is)

small focal spot limits current

Effective focal spot

• Area that is projected out of the tube and toward the patient

• Controlled by the actual focal spot

how is the size of focal spot related to spatial resolution

• Impacts image spatial resolution (detail)

• Inverse relationship with focal spot size

• Smaller focal spot = increased (better) resolution

Line Focus Principle

• The relationship between the actual focal spot and the effective focal spot

• The size of the effective focal spot will depend on the angle of the target on the anode

• Most common target angles are 12 degrees

• Larger angle = larger effective focal spot

• Smaller angle = smaller effective focal spot

Anode Heel Effect

• Due to geometry of anode design (angled target)

• Results in variation of x-ray beam intensity along longitudinal axis of x-ray beam

Cathode to anode axis

Total beam intensity can vary as much as 45%

• More intense under cathode side of tube

• Intentional positioning of body parts can take advantage of heel effect

(beam hits the anode heel, electrons get absorbed, therefore weaker beam on the anode side)

Warm-Up Procedure

• Only for some xray machines (most digital machines do not require)

• Gradually warms anode

Prevents cracking glass envelope in older machines

Helps maintain vacuum

• Recommendations vary between x-ray tube manufacturers

• Should be performed if tube has been idle for an extended period of time

> 2 hours

Check with tube manufacturer

Envelope

• Heat tolerant Pyrex glass or metal

• Two functions

Supports anode/cathode assemblies

Maintains a vacuum to avoid debris and disturbances

• Modern tubes now metal

10ʺ long

6ʺ central diameter

2ʺ peripheral diameter

• Tube Window

Area constructed for x-ray beam to exit

Protective Housing

• Metallic; lead lined cast steel

• Supports x-ray tube

• Controls leakage and scatter radiation

Lead lined

• Isolates high voltages

• Provides mechanisms to cool tube

Cooling oil surrounding tube

Cooling fans

Water cooling in high-end tube designs

Off-Focus Radiation

• Undesirable part of the beam produced away from the target and therefore considered “off focus”

• Contributes up to 25 percent of total primary beam

Low energy and of no diagnostic value

Collimator design blocks a significant portion (very important to collimate!)

• Produces “ghosting” of image and reduces image quality

• Can be corrected with post processing in digital radiography

Extending X-Ray Tube Life

• Follow recommended tube warm-up procedures

• Avoid frequent and successive “boosting” of tube

• Use low mA settings when possible

• Avoid rough handling of x-ray tube head

• Listen for unusual sounds

Report these to service engineer via supervisor