Innovations in Degradable Polymers

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

32 Terms

why aren’t most research articles pursued by industry?

not economical

takes many years to implement on industrial scale

what does catalytic chemical recycling of post-consumer polyethylene start with?

post-consumer water jug (shred it)

steps of catalytic chemical recycling of post-consumer polyethylene

react shredded water drug w dehydrogenation catalyst → 0.5% of C-C backbone bonds dehydrogenated to C=C w/o change in MW

cross-metathesis w 2-hydroxyethyl acrylate → MW goes down (chains breaking)

hydrogenation of C=C bonds

transesterification with diethanolamine (8% reacts)

repolymerization w MW = 80kDa → tensile strength now similar to og HDPE

depolymerization w ethylene glycol and triazabicyclodecene (TBD) → once recycled to monomer, can be repolymerized

step 1 of catalytic chemical recycling of post-consumer polyethylene

react shredded water drug with dehydrogenation catalyst

approximately 0.5% of C-C backbone bonds dehydrogenated to C=C double bonds without a change in MW

essentially installing double bonds/unsaturated units without breaking polymer

step 2 of catalytic chemical recycling of post-consumer polyethylene

cross-metathesis with 2-hydroxyethyl acrylate (cheap)

essentially switch partners of double bond, adding new endgroup (breaking polymer chains in the process)

results in ethylene byproduct

end group = hydroxymethyl methyl methacrylate

MW goes down quite a bit due to chains breaking

step 3 of catalytic chemical recycling of post-consumer polyethylene

hydrogenztion of C=C bonds

now only C-C single bonds

repolymerization after this step made similar polymer Mn but much smaller Mw

→ brittle & poor tensile behavior bc of lower Mw

step 4 of catalytic chemical recycling of post-consumer polyethylene

transesterification with diethanolamine (8% of hydrogenated material reacts)

step 5 of catalytic chemical recycling of post-consumer polyethylene

repolymerization with Mw - 80 kDa

tensile strength now similar to original HDPE

step 6 of catalytic chemical recycling of post-consumer polyethylene

depolymerization with ethylene glycol and triazabicyclodecene (TBD)

once chemical is recycled to monomer, can be repolymerized (circular)

cross metathesis

type of olefin metathesis rxn that involves the exchange of substituents b/w different olefins thru the breaking & reforming of C=C bonds

catalyzed by metal complexes

transesterification

process of exchanging organic functional group of an ester with an alcohol

which new research innovation is a bottom-up approach?

chemically

bottom-up approach

synthesize monomer first and then polymerize/recycle it (start with a chemical reaction)

starting point for Chemically Recyclable Linear and Branched Polyethylenes

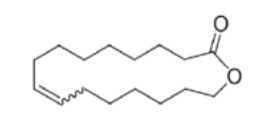

lactone

a cyclic compound with an ester and an internal double bond

steps of Chemically Recyclable Linear and Branched Polyethylenes

ring open with methanol reflux & Sc catalyst (lewis acid accepts e- pair)

ring-opening metathesis polymerization w cyclooctenehydrogenate

Hydrogenation → yields telechelic monomers (2 different reactive end groups)

Transesterification for polymerization → no matter size of starting monomers, high MW polyethylene obtained

depolymerization by methanol reflux & Sc catalyst

what is required for branched polymerization via Chemically Recyclable Linear and Branched Polyethylenes?

trifunctional monomer

step 1 of Chemically Recyclable Linear and Branched Polyethylenes

ring open w methanol reflux & Sc catalyst

Sc catalyst = lewis acid that accepts an electon pair, making C more electrophilic

step 2 of Chemically Recyclable Linear and Branched Polyethylenes

ring opening metathesis polymerization with cyclooctene

step 3 of Chemically Recyclable Linear and Branched Polyethylenes

hydrogenation

Mn was selected in the range b/w 2-16 kDa

yields telechelic monomers (2 diff reactive end groups)

A reacts w B on another monomer

telechelic monomers

type of polymer that has reactive groups located at both ends of linear structure

step 4 of Chemically Recyclable Linear and Branched Polyethylenes

transesterification for polymerization

no matter size of starting monomers, high MW polyethylene obtained (~100kDa)

step 5 of Chemically Recyclable Linear and Branched Polyethylenes

depolymerization by methanol reflux & Sc catalyst

can do branched polymerization with a trifunctional monomer

which approach starts with a system known to be easily chemically recycled?

Chemically Recyclable Thermoplastics from Cyclic Acetals

what polymer is known to be easily chemically recycled and used in Chemically Recyclable Thermoplastics from Cyclic Acetals?

poly(acetals)

poly(acetals)

easily recycled to monomer using trace acid and heat (<150C)

liquid

easily distilled off in high purity

in the past, MW weren’t high enough to make useful materials

high MW version has good tensile strength

the high MW version of poly(acetals) has good _______ strength

tensile

pros of poly(1,3-dioxoiane) - a chemically recyclable thermoplastic

tough thermoplastic

thermally stable to 325 C

monomer recovered in 98% yeield

synthesized from inexpensive monomer w bio-sourcing options

rapidly polymerized

describe use of RD-CROP of cyclic acetals

start with dormant species with X group

MOMBr adds Br to end of growing polymer chain forming active species

Br stabilizes and allows high MW to be reached with high control

monomer addition

cycles back to dormant species

the stress-strain curve for PDXL is very similar to which commercial polymer?

iPP = isotactic poly(propylene)

triggered depolymerization enables…

chemical recycling to monomer

steps of triggered depolymerization → chemical recycling in Chemically Recyclable Thermoplastics from Cyclic Acetals

collect polymer

add acid, heat to 140-150

distill

recover monomer

can pure DXL be recovered from mixed waste stream?

yes

96% recovery