Sub-Surface Test 2

1/101

Earn XP

Description and Tags

Wireline+Perforating+Wellbore Integrity & CBLs

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

102 Terms

What is the primary objective of a perforating gun?

To provide effective flow communication between a cased wellbore and a productive reservoir

What types of logs are used to correlate perforation depth?

Gamma Ray

Casing Collar Locator (CCL) Logs

Name the 2 methods of perforating

Jet perforation

most common

shaped charge; high velocity gas

Bullet perforation

Name 1 benefit and 1 drawback of jet perforating

Benefit: minimizes casing and cement damage (compared to bullet perforation)

Drawback: can leave debris in the formation

TorF: Bullet perforating is mainly used to perforate in deep formations

False

it is used in moderately compressed (ie. shallow) formations

it produces shorter, smaller-diameter perforations and can’t effectively penetrate deep, compact, or high-pressure formations

Name 5 methods of perforating gun actuation (ie. triggering)

Electronic signal on e-line

Drop bar (mechanical)

Ball drop

Hydraulic delay

Programmable firing head

In the picture of a shaped charge shown, in which direction does the shot fire?

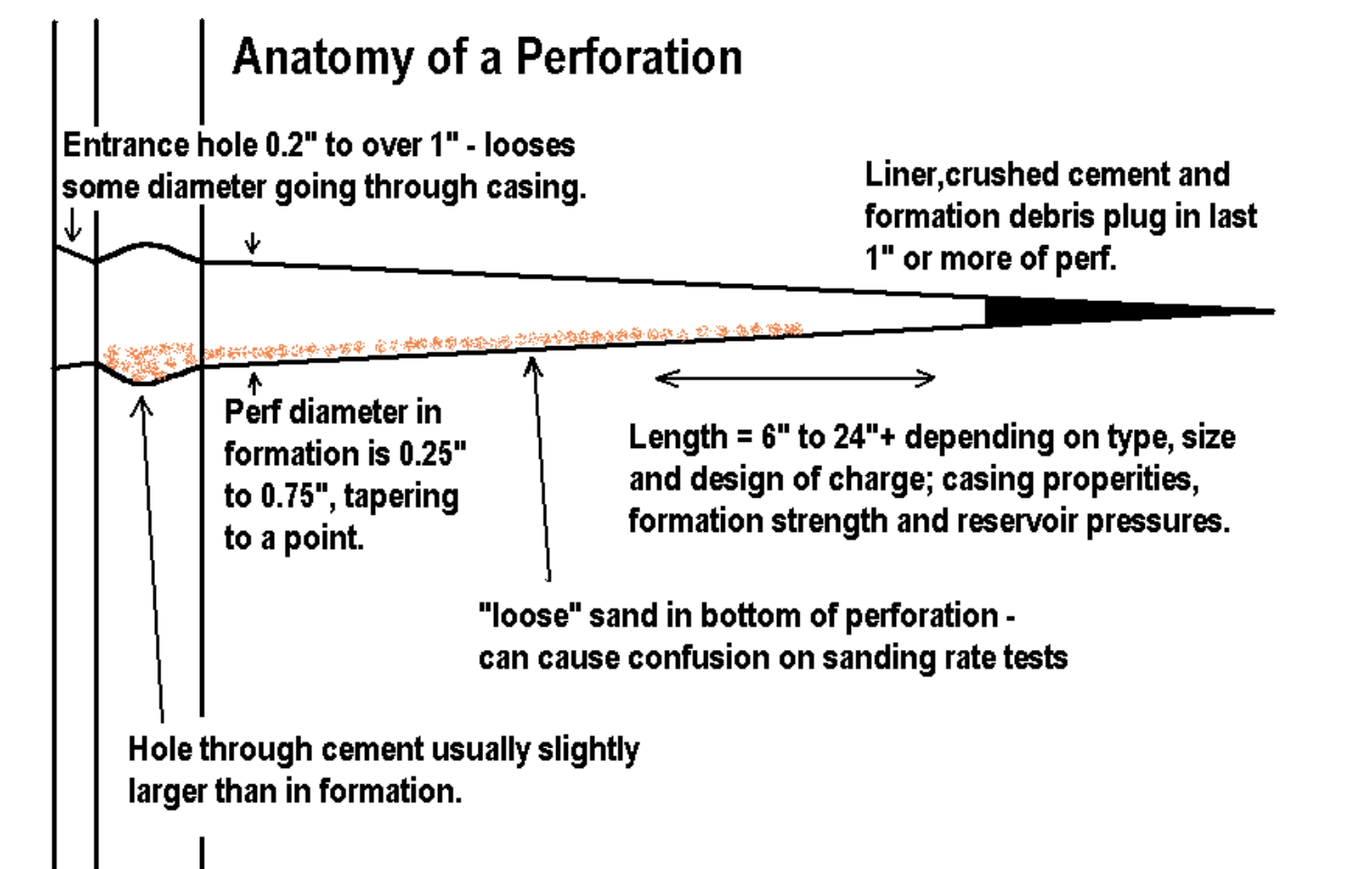

What is a typical range of perforation lengths?

6” to 24”

depending on type; size and design of charge; casing properties; formation strength; reservoir pressure

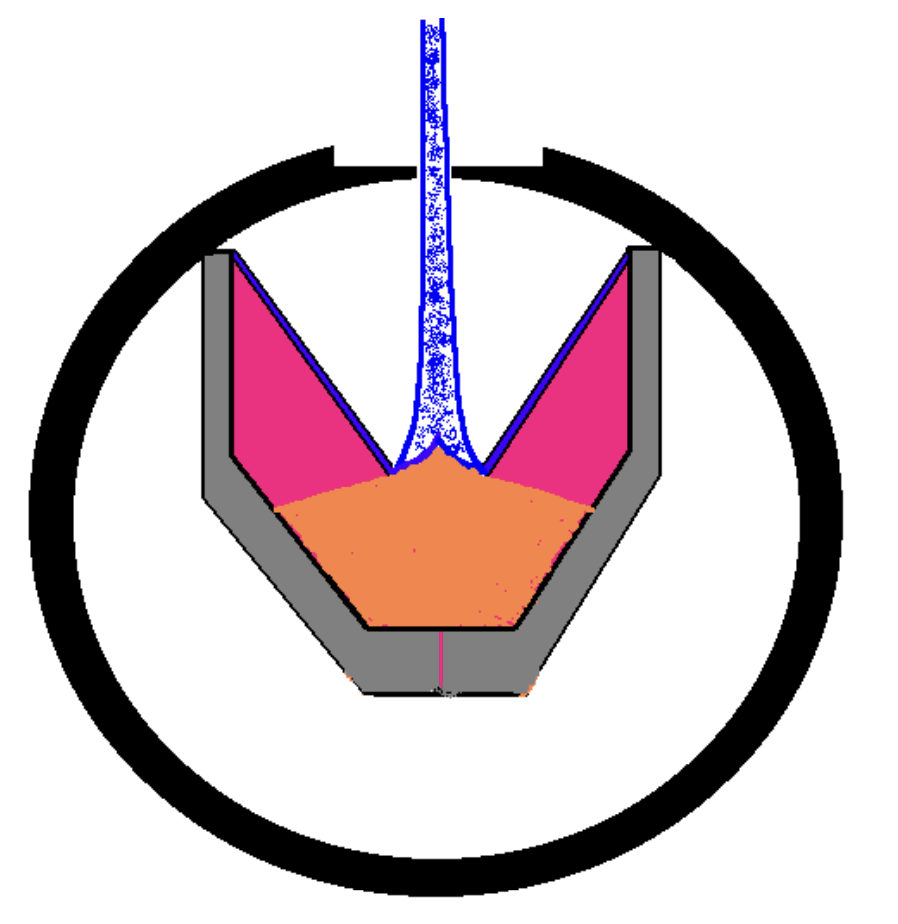

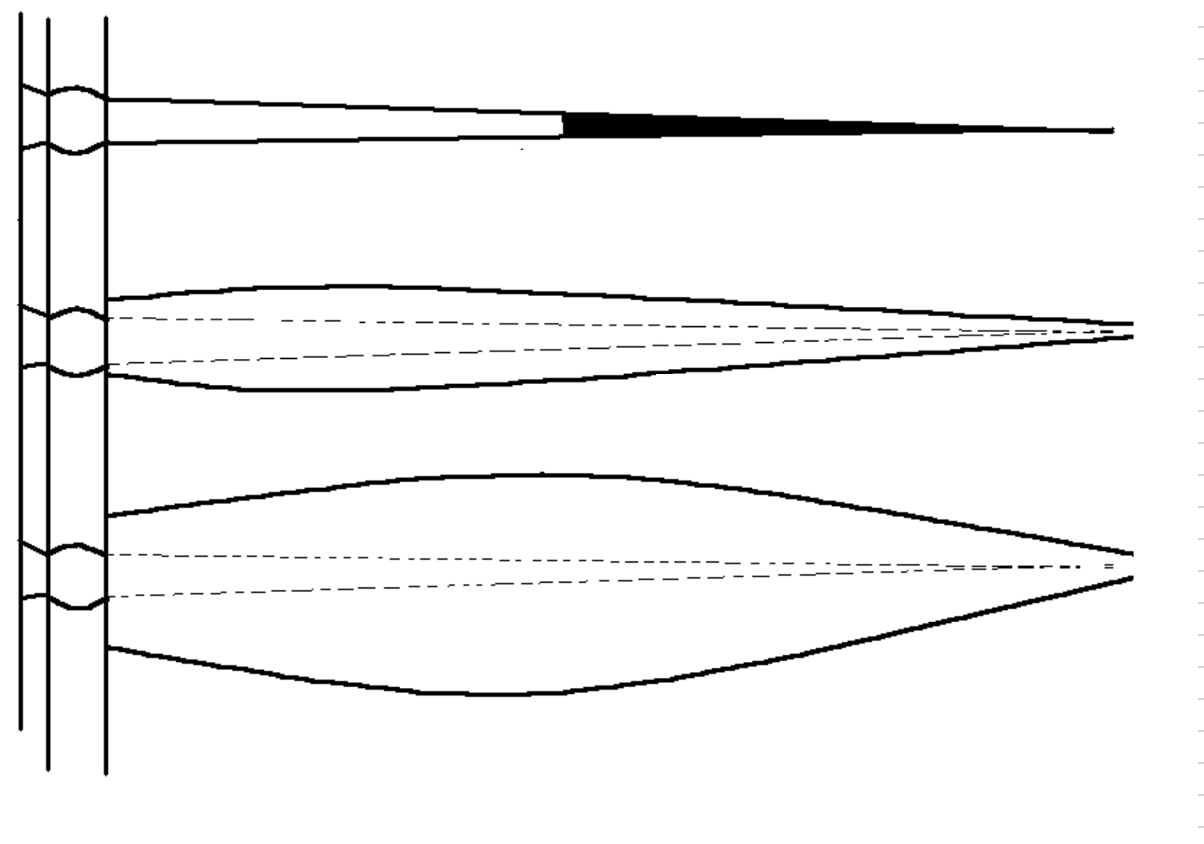

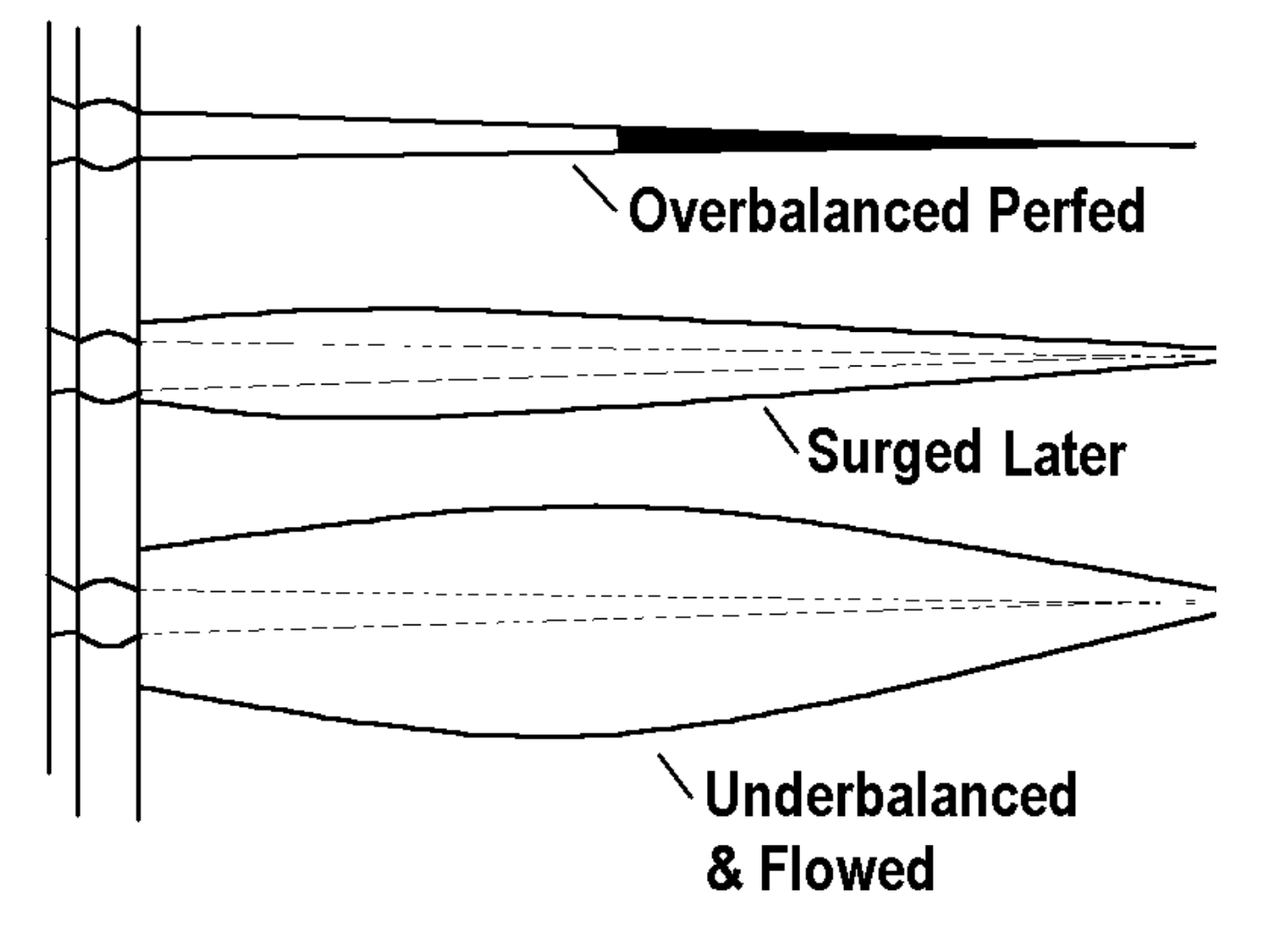

Of the 3 perforations shown, which one was shot ‘underbalanced and flowed’ ?

While perforating underbalanced, the pressure differential from the formation to the wellbore (ie. inflow) helps remove the crushed formation from the perforation and provides an improved flow channel

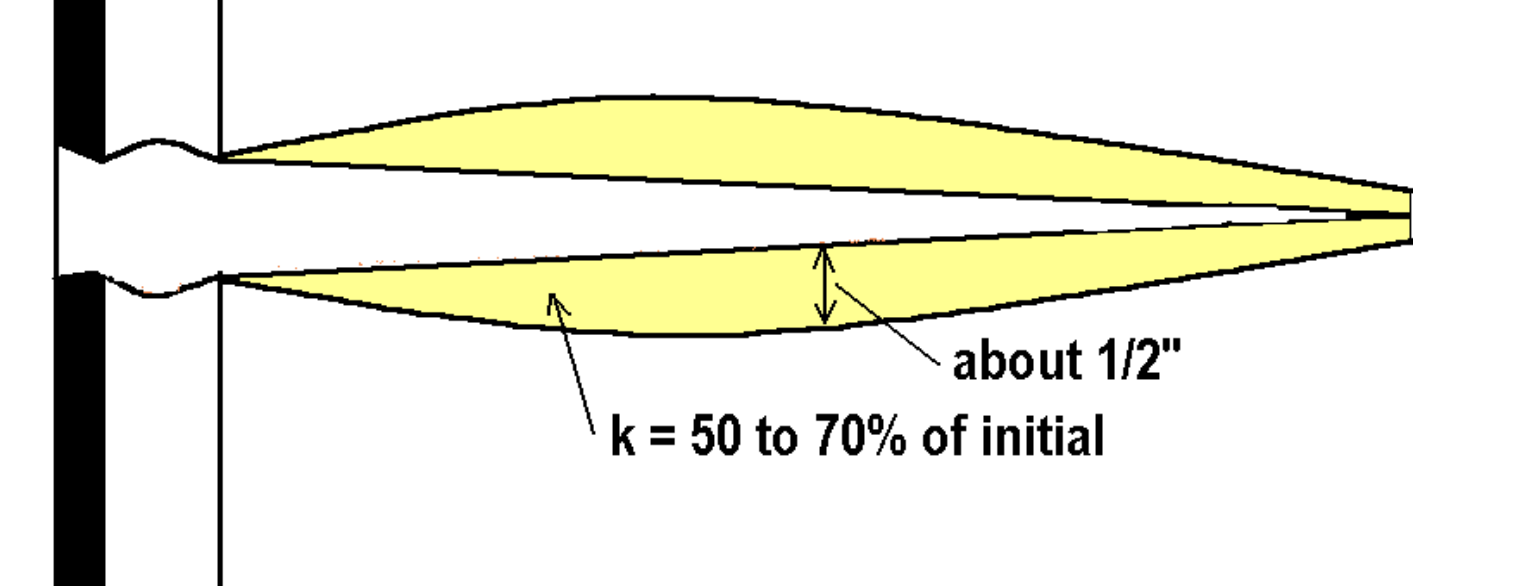

TorF: It is common to see a loss of permeability in the rock immediately surrounding a perforation tunnel

True

When a perforation is created — whether by bullet or jet — the shock, heat, and pressure from the explosive event damage the formation near the tunnel. This creates what’s called a “crushed zone” or “compacted zone.”

The grains in this zone are fractured and compacted, reducing pore space and blocking flow paths.

Fine particles can also be smeared or melted, plugging pore throats.

As a result, permeability near the perforation is lower than the native formation permeability.

Name 5 types of conveyance methods for perforating guns

• Wireline conveyed (vertical)

• Pump down perforating

• Tractor conveyed (on wireline; horizontal)

• Tubing conveyed perforating (TCP)

• Coiled tubing perforating

TorF: A dropbar is used to detonate a perforating gun run on e-line

False

Dropbars are solid steel bars that can be dropped through tubing or on slickline to set off an impact detonator

The most cost-effective and quickest method of perforating, which should be used in vertical and low deviated wells

Wireline perforating

Which perforating technique would best be used in horizontal multi-stage treatments?

a) Wireline perforating

b) Pump-down perforating

b) Pump-down perforating

can’t push a wire

Commonly used to perforate the toe intervals of wells that then use pump down for the remaining intervals

Tractor perforating

Which perforating technique is the most likely to create open, undamaged perforations?

a) Underbalanced

b) Balanced

c) Extreme Overbalanced

a) Underbalanced

the pressure differential from the formation to the wellbore (ie. inflow) helps remove the crushed formation from the perforation and provides improved flow channels

used on natural completions where stimulation is not planned

On a perforating job for a horizontal shale gas well that will eventually be fraced, what type of perforation technique would most likely be used?

a) Underbalanced

b) Balanced or Extreme Overbalanced

b) Balanced or Extreme Overbalanced

you will be fracturing through the perfs anyway, so there is no need for immediate flow into the well (which you’d get w/ underbalanced)

your main goal is to maintain control of the well, which balanced (usually slightly overbalanced) or extreme overbalanced achieves

A well has been perforated from 2304.5-2306.5m at 60° phasing, shot at 7 spm. How many total perforation holes are there?

2m x 7 shots/m = 14 shots = 14 holes

Name three types of perforating carriers (there are two specific types, with one having a sub-category)

1) Expendable

2) Retrievable

Scalloped

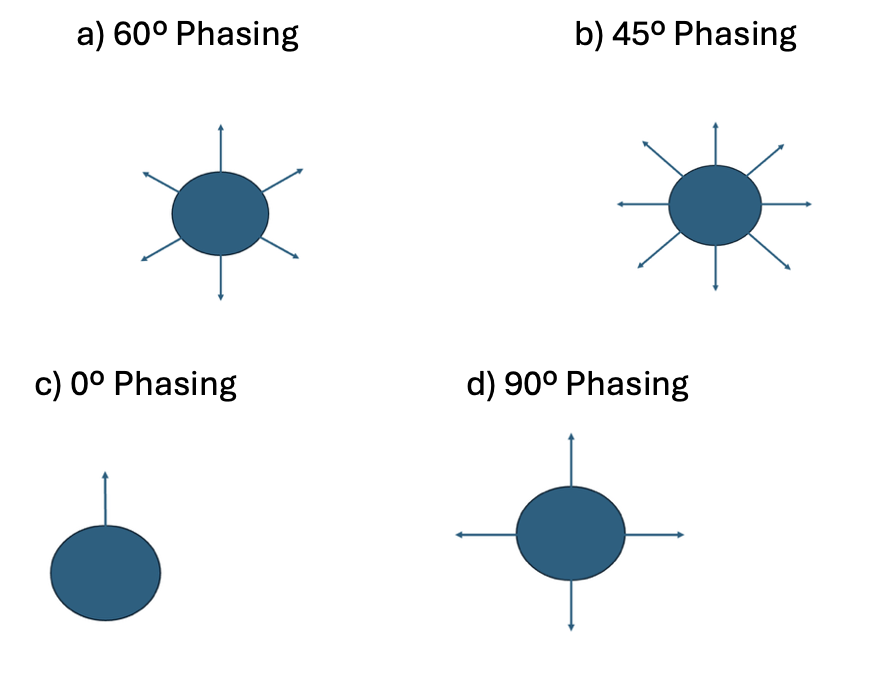

Sketch top view pictures of the following phasing setups:

a) 60°

b) 45°

c) 0°

d) 90°

When designing a perforating program, what resource would you use to determine the length of the interval to perforate?

You only want to perforate the productive zone, so therefore you would use formation evaluation logs:

Gamma Ray Logs

Porosity/Resistivity Logs

A precisely machined tool used to confirm the internal diameter of downhole tubulars like casing, tubing, and drill pipe, ensuring they meet operational specifications and are free from obstructions or deformations.

Drift gauge

A tool run on e-line or slickline that is used to place small volumes of cement slurry in a wellbore

Dump bailer

A type of well test designed to measure the pressure gradient within the wellbore when the well is not flowing. It helps determine the bottomhole pressure and the presence of fluids downhole.

Static Gradient

To what depth below the lowest water-bearing zone must surface casing be cemented for injection or disposal wells?

25m

A method used to detect gas migration from oil and gas wells. Performed at the wellhead, it evaluates the integrity of the well and identifies any leaks or gas emissions

Surface Casing Vent Flow (SCVF) test

Tests for the flow of gas or liquid that is detectable at surface outside of the outermost casing string

Gas Migration Test

A pressure test of the tubing and casing annulus that is designed to evaluate the integrity of the wellhead, casing, tubing, and packer

Packer Isolation Test

To prep for a perf job, a company wants to perform a formation property analysis (ex: stress, rock strength, etc.) to optimize perforation design. Which open-hole log should be performed?

Sonic (Acoustic) Log

Why run a Gamma Ray log when placing a bridge plug?

To correlate depth accurately.

The gamma ray log records natural radioactivity in the formations, giving a unique “fingerprint” vs. depth.

By matching gamma ray trace with a previous open-hole gamma ray log, the operator can:

Confirm exact depth inside the wellbore, and

Ensure the bridge plug is set at the intended formation or zone boundary (e.g., above perforations, water zone, or pay interval).

What is the first thing you do to a newly drilled and cemented well?

In other words, what is the first step in any completion?

Install the tubing head

What type of fluid would you expect to find left in a newly drilled and cemented well?

Whatever the drilling company left in it

typically drilling mud or completion fluid

A company plans to reverse circulate in order to kill a flowing oil well. At what point on the wellhead would they hook up in order to kill the well?

Into the flow tee on the tubing spool

reverse circulate means you’re pumping down the annulus

For an abandonment, when would a cement retainer be run?

On a sour well

Nipples have profiles. Describe what profiles are and what their function is.

A precisely machined internal shape inside the nipple that allows for engagement with tools

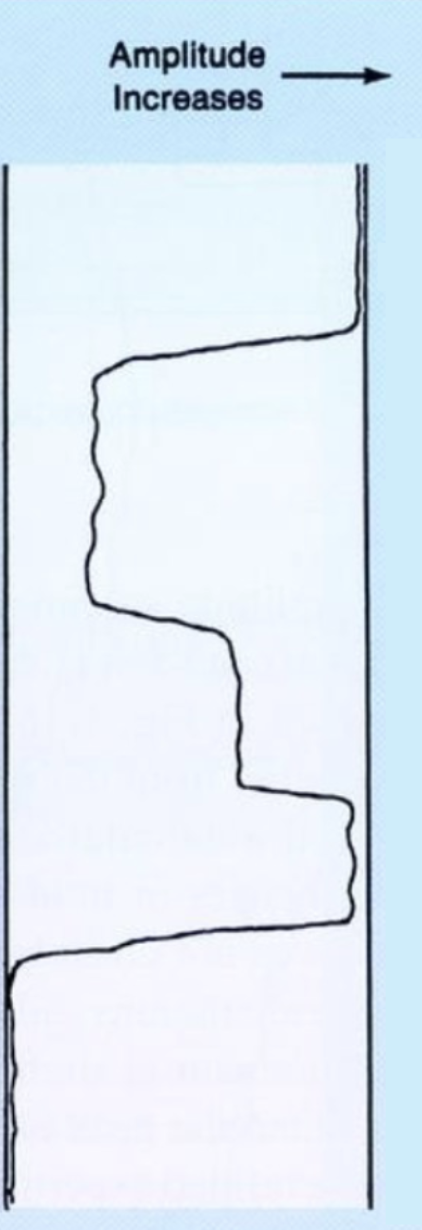

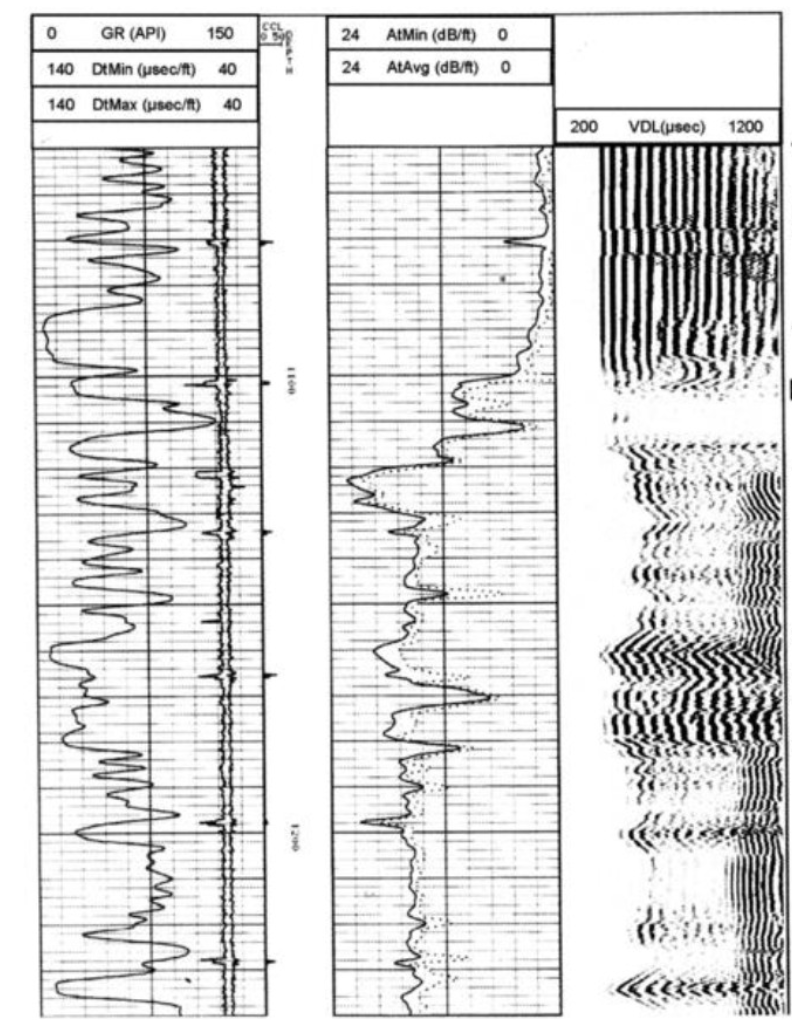

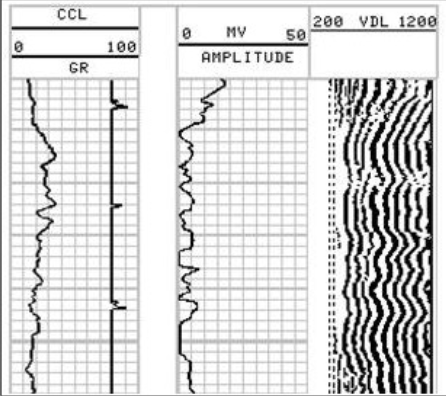

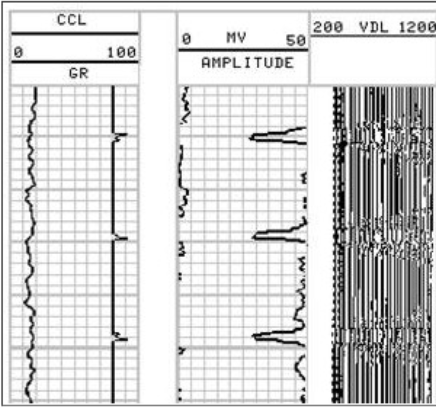

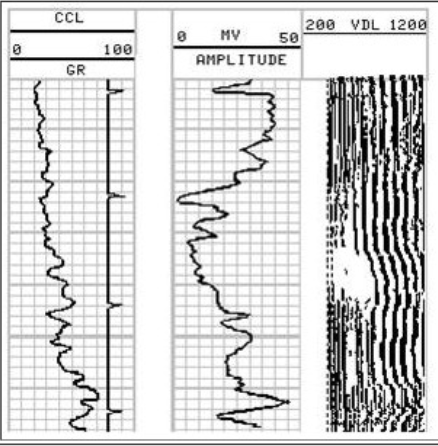

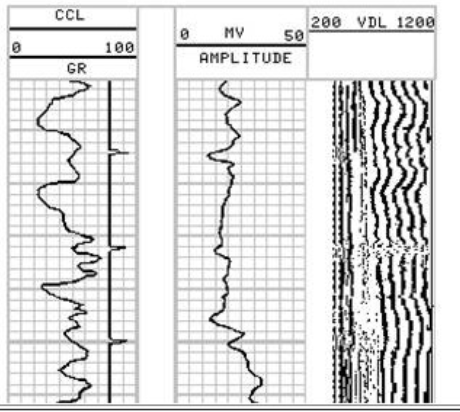

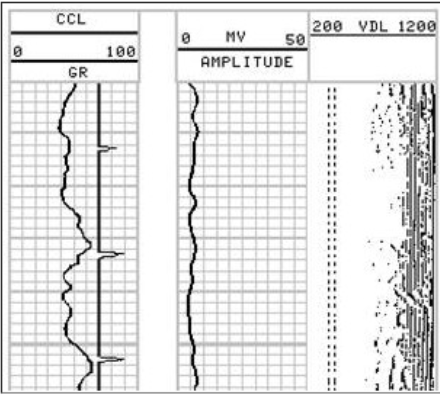

Name the 4 curves typically found on a Cement Bond Log

Gamma Ray

Casing Collar

Variable Density

Attenuation/Amplitude (Bond Log)

This log shows natural radioactivity vs. depth

Gamma Ray

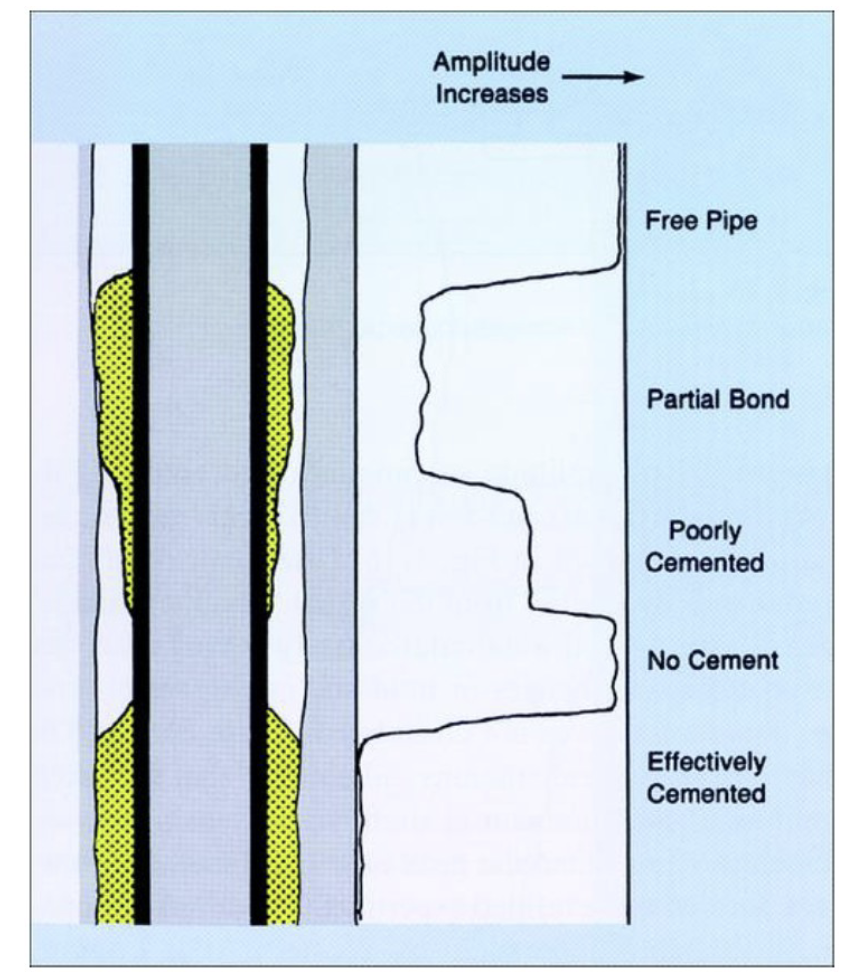

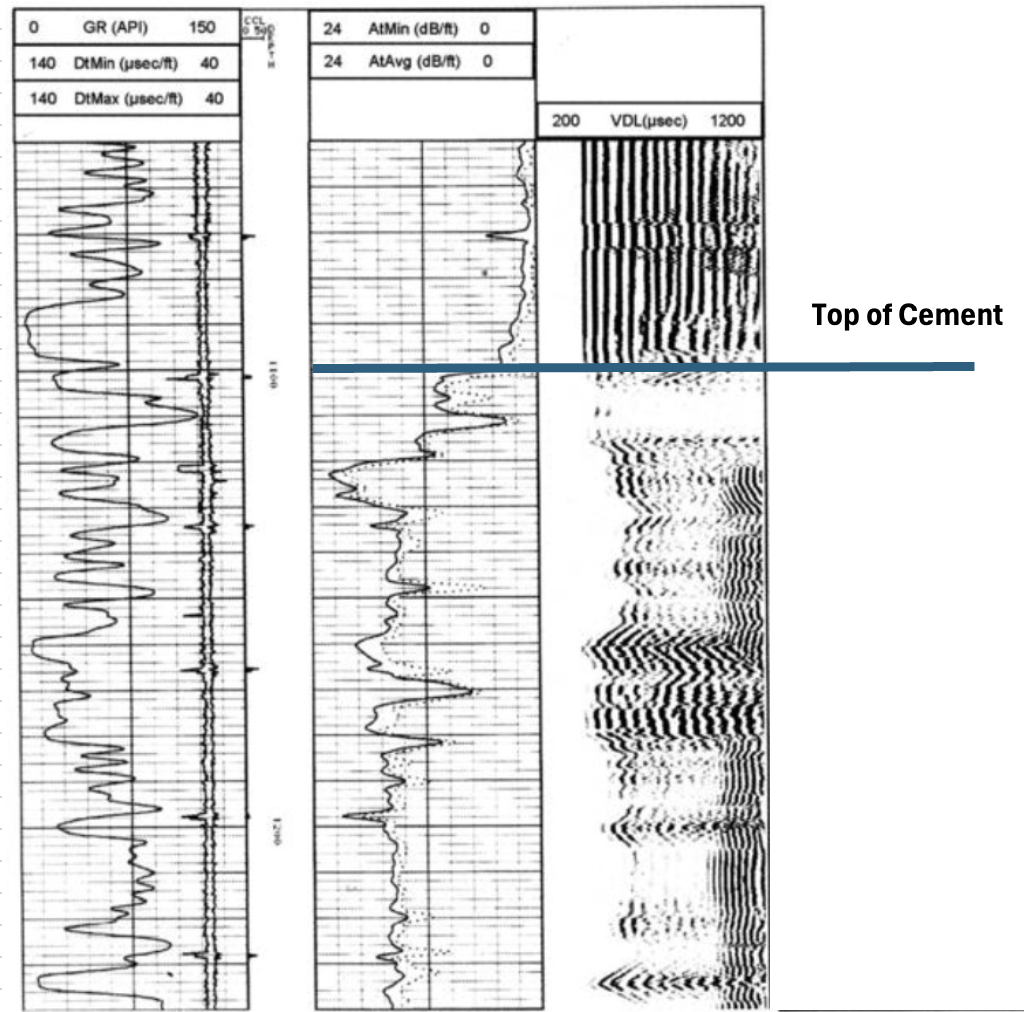

On a cement bond log, what would be indicated by:

a) High amplitude

b) Low amplitude

The amplitude curve shows the strength of the returning sonic signal received by the tool

High amplitude = strong returning signal → poor cement bond (sound travels freely - cement too shitty to absorb it)

Low amplitude = weak returning signal → good cement bond (sound energy absorbed by cement and formation)

On a cement bond log, what would be indicated by:

a) High attenuation?

b) Low attenuation?

Attenuation measures how much sonic energy is absorbed or lost as it travels from the transmitter, through the casing, cement, and into the formation.

High attenuation = high energy loss → good bond (energy absorbed by cement/formation)

Low attenuation = low energy loss → poor bond (energy mostly reflects back b/c cement too shitty to absorb it)

A company wants to measure the amount of flow coming from different sets of perforations within the wellbore. What type of log should they run? What type of conveyance would be used?

Spinner log

Spinner logs are run on wireline

A non-sonic log that is run in producing wells to locate production sources downhole. Can also detect flow channels behind casing, as well as areas within a formation that are accepting injected fluids.

Temperature logs

Temperature surveys operate on the principle that temperature increases with depth below the surface (the geothermal gradient).

When a temperature survey measures a temperature in a well that is significantly deviated from the geothermal profile, that temperature anomaly is a possible point of fluid flow, entry or injection.

The anomaly could be confirmed as fluid with a noise log

These logs use microphones to detect fluid movement downhole

Noise log

Noise logs depend upon fluid moving at sufficient velocities to create turbulence so that the movement can be heard

Often run in conjunction with temperature logs

Which log can be run while moving through the wellbore - temperature logs or noise logs?

Temperature logs

Noise logs are run by wireline and position the tool against the casing at a predetermined spot.

Noise logs cannot be run while the tool is moving, because tool and cable movement noise will drown out all other sounds.

Therefore, noise logs are more of a diagnostic tool than an investigative tool, because they cannot locate the problem areas, but can be positioned in a suspected problem area to confirm whether there is a problem.

As a result, noise logs are usually run in conjunction with a temperature log.

The temperature log can record while moving, so it can isolate areas of fluid movement that can later be verified with a noise log.

What is the foundation of the wellhead assembly?

Casing head

When running wireline, at what point on the wellhead is the lubricator connected?

Top of the christmas tree

Which is stronger, slickline or braided line?

Braided line

used in deep wells or for fishing

On wireline operations, this is a device used to deploy tools in horizontal wellbores

Tractor

Which of the following logs is more suited to diagnostics, and which more suited as an investigative test?

Temperature log

Noise log

Temperature log → investigative (can run while moving to find fluid flow)

Noise log → diagnostic (cannot run while moving, so is often used as a confirmation test once the temperature log detects an area of interest

In perforating, this is the angle differential between shots

Phasing

What is the most common SPM in Westen Canadian perf jobs?

13 SPM

What is the purpose of the scallops on a perforating gun?

Primarily to contain the metal burr around the perforation exit hole, preventing damage or scoring to polished bore surfaces, such as those on packers and profiles.

also reduces the thickness of the gun body through which the charge must penetrate

Are packers typically used in pumping oil wells? Why or why not?

Never

Multi-phase flow in an oil well requires an open annular space to offload the solution gas (necessary to prevent pump lock-up)

This component, installed as part of the production string, is used for the safe re-entry of wireline tools from the casing back into the tubing string

Wireline re-entry guide

Name 3 ways that perf charges can be detonated

Electric charge (electrically)

Pressure (hydraulically)

Impact (mechanically)

Name two methods of conveying wireline over horizontal sections

Fluid conveyance (pump-down)

Tractor conveyance

A well service operation that uses the drilling rig’s hoisting and/or power systems to assist the service

Rig-Assist Servicing

For a wireline operation in which advanced logging tools that require multiple data channels will be run downhole (ie. formation evaluation logging), what type of wireline would be used?

Multiconductor E-line

What are the three main types of casing inspection logging tools?

1. Mechanical

Multi-finger cased-hole calipers

measures ID only

2. Electromagnetic

Induced electric current creates magnetic field

Magnetic field is sensed and variations correspond to irregularities

Detects internal and external corrosion (wall thickness)

Cannot detect scale or wax buildup

3. Ultrasonic

Rotating ultrasonic transducer emits high frequency sonic signal

Travel time for signal to return is indicative of casing ID

Frequency of signal is proportional to wall thickness

Can determine casing ID, ovality, thickness

Requires fluid filled borehole

What are the 2 main applications of production logs?

Assessing well flow profile and fluid type

Diagnose wellbore production problems (unproductive perf clusters, etc.)

TorF: A service rig is necessary in order to run production logging tools

False

They are run on:

e-line

slickline

coiled tubing

TorF: Running a logging tool on a slickline is very convenient, as a real-time surface readout can be obtained

False

Nothing through which to send the signal on a slickline for a surface read-out

would need e-line

Any logging on slickline would be run in memory mode

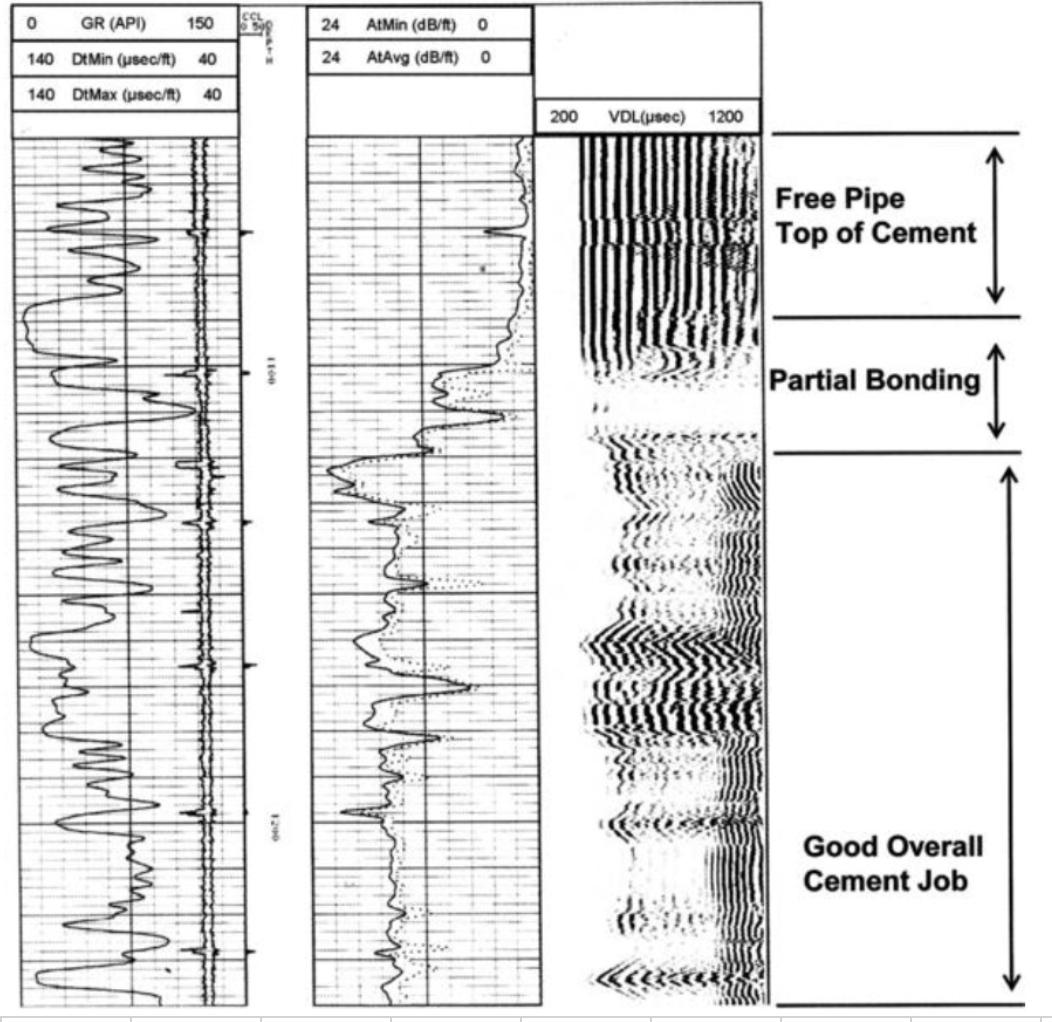

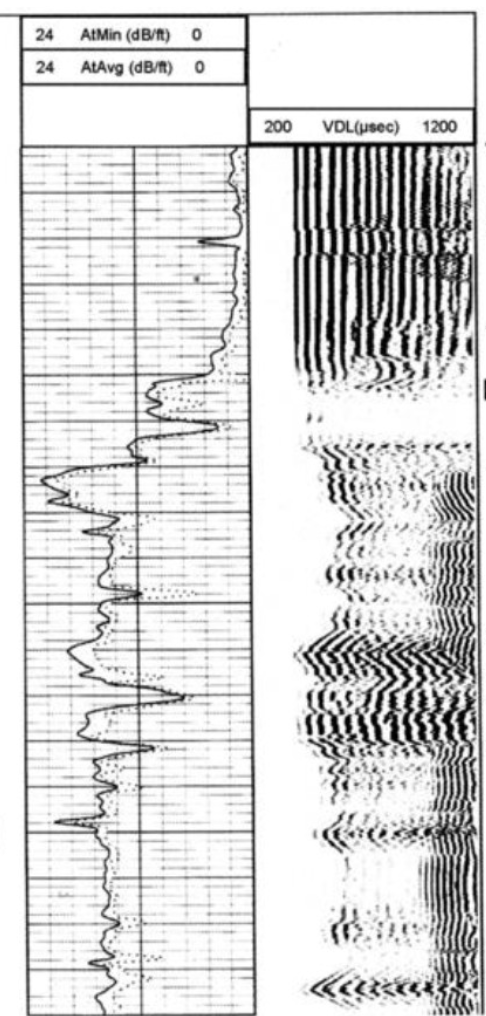

On the cement bond log shown, identify each of the 5 distinct readings as either:

Free Pipe

No Cement

Partial Bond

Effectively Cemented

Poorly Cemented

High amplitude = bad/no cement

TorF: Electromagnetic casing inspection logs can be used to detect wax/scale build-up

False

they rely on electromagnetic induction

wax/scale is non-metallic

Caliper logs could be used, as these will mechanically detect inner diameter reductions (which could be wax or scale)

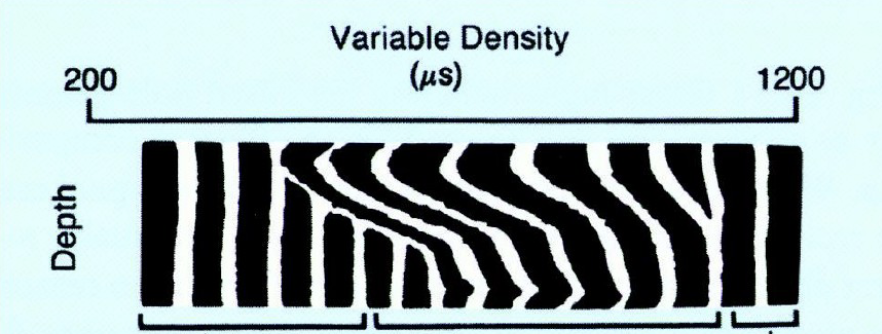

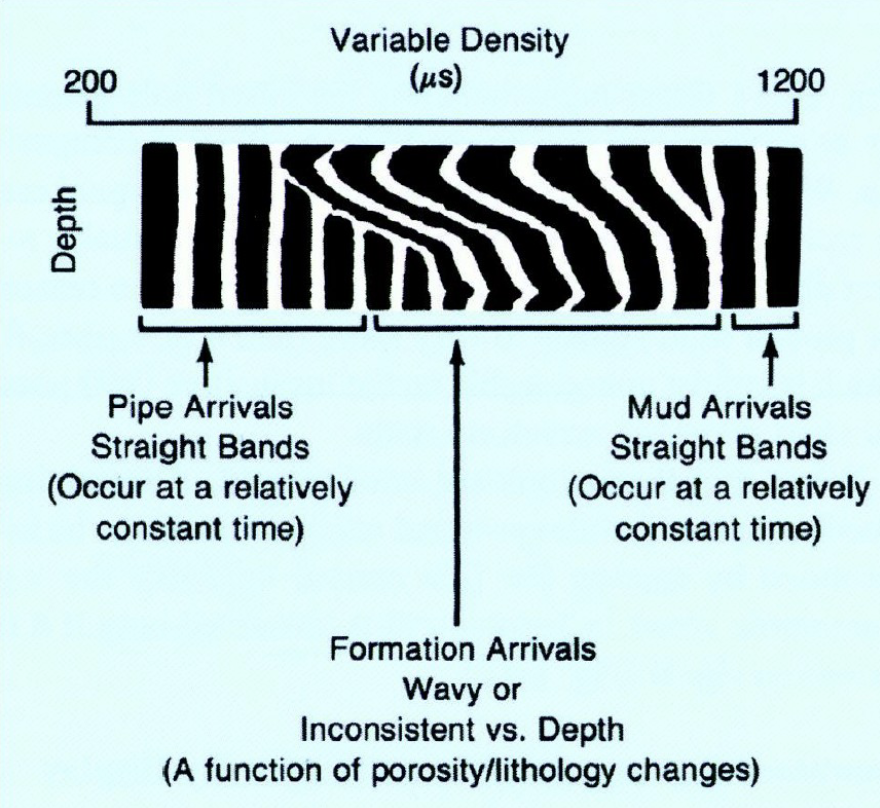

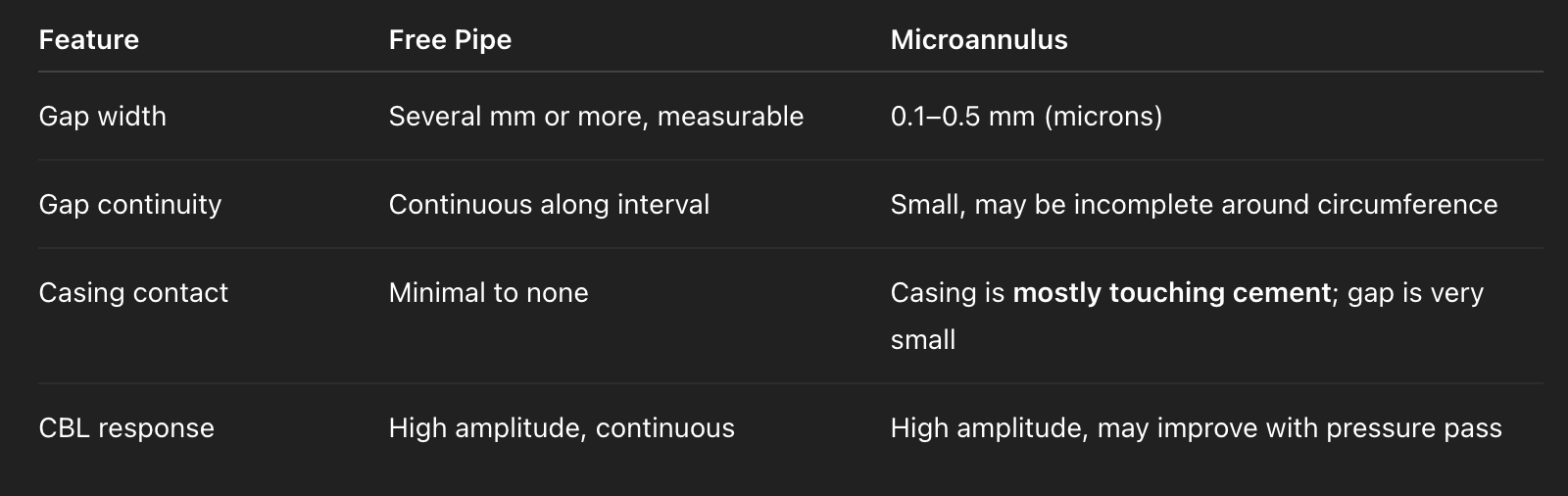

On the VDL read-off shown, identify:

Pipe arrivals

Mud arrivals

Formation arrivals

The first, sharp sonic reflections that are recorded by a variable density log correspond to:

a) Formation arrivals

b) Mud arrivals

c) Pipe arrivals

c) Pipe arrivals

Name 2 ways that a micro annulus can form

Temperature/pressure changes

casing can contract following temperture/pressure changes, which may open up a micro annulus b/w the cement and casing

Cement shrinkage

cement shrinks slightly as it cures, which could cause it to pull away from the casing or formation, forming a micro annulus

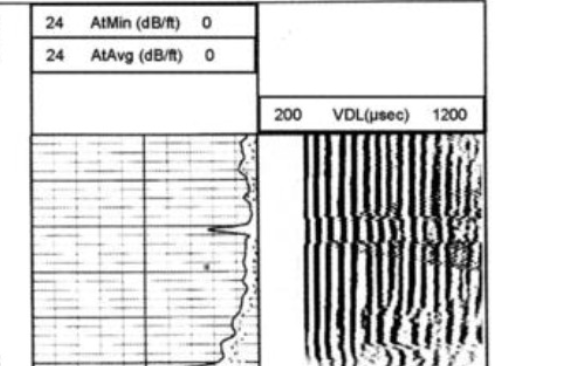

TorF: Micro annuli are normally less than 1mm across

True

TorF: A standard CBL log will detect small channels in the cement

False

The sonic signal averages over the circumference of the casing

Tiny or thin channels (less than a few mm) may not change the overall signal enough

Would have to run a Radial Bond Tool to detect small channels

Provides circumferential imaging, not just an averaged response

TorF: Production logs are normally run on producing wells and through tubing

True

Identify the following areas:

partial bonding

good cement

free pipe

Of the following common cement problems, which is the one most likely to be misinterpreted as free pipe?

a) Microannulus

b) Channeling

c) Poor centralization

d) Gas cut

a) Microannulus

Per AER guidelines, when abandoning a sour well, what height of cement is required above the cement retainer?

30m

According to Espo - couldn’t find that in Directive 20

Per AER guidelines, when abandoning a sweet well, what height of cement is required above the cement retainer?

8m

What, specifically, does a spinner log measure?

Fluid velocity

Which of the following casing inspection logging tools requires a fluid filled wellbore?

a) Caliper

b) Ultrasonic

c) Electromagnetic

b) Ultrasonic

Requires a fluid-filled wellbore to transmit the signal between the tool and the casing wall.

Without fluid, sound waves cannot travel effectively — you’d get no return signal.

Which type of perforating carrier can be run in a well under pressure?

Hollow Carrier gun

Hollow carrier perforating guns are pressure-tight, with the shaped charges sealed inside a steel housing (the carrier)

Because the explosives and wiring are isolated from well fluids and pressure, the gun can be safely run and fired in a well under pressure

What is the difference between a SCVF test and a gas migration test?

Surface Casing Vent Flow (SCVF) Test

Detects gas or liquid flow that is venting to surface through the surface casing vent (i.e. inside the annulus between the surface casing and the next casing string).

Indicates:

The cement job b/w the surface and next casing string has failed to isolate one or more formations - gas is migrating through channels, micro-annuli, or poor bond zones in that cement column

Test method:

The surface casing vent is opened to measure flow rate and composition, or pressure buildup is monitored when closed

Gas Migration (GM) Test

Detects gas leaking outside the surface casing, through the surrounding soil, to the ground surface.

Indicates:

The cement b/w the surface casing and formation is not providing full isolation — gas is migrating through channels, micro-annuli, or poor bond zones in that cement column

Test method:

Gas detectors or probes are placed in the soil near the wellhead to measure methane concentration or bubbling in water

Which curve on the Casing Bond Log should be referenced in order to discern the quality of the bond between the cement and the formation?

Variable Density Log (VDL)

Good Cement

No Cement

Partial Cement

Micro annulus

Cement w/o bond to formation

Once a retrievable perforating gun has been fired and brought back to surface, what remains?

Hollow steel carrier

Can the pipe to cement bond be reliably measured in a fast formation?

No

A fast formation (like limestone or dolomite) transmits the sonic signal very quickly.

The formation arrival (the signal that travels through cement and formation) can overlap or arrive almost simultaneously with the first casing arrival.

This interference makes it difficult to distinguish between:

Energy traveling through the casing (free pipe), and

Energy traveling through the bonded cement and into the formation.

As a result, the log might falsely indicate poor bonding even when a good bond exists

TorF: The CBL amplitude can be used to reliably indicate the quality of the bond between the cement and the formation

False

The CBL amplitude curve shows the amplitude of the first signal to arrive → and hence primarily reflects the quality of the cement-to-casing bond

for insight into the cement-to-formation bond, check the VDL

For CBL amplitude:

High amplitude → poor casing-to-cement bond (or free pipe)

Low amplitude → good casing-to-cement bond

Your plan is to abandon a non-producing zone in a pumping oil well and perforate a separate zone of interest in order to bring production back online. Arrange the following steps in the order that the operation would be carried out:

Swab well down to +/-1060mKB

MU and RIH with casing guns and perforate zone of interest from 1035.0 - 1037.0 mKB and 1043.0 to 1046.0 mKB

RU tubing inspection equipment, pull and inspect 73.0mm tubing

MORU service rig

MORU Wireline unit and set permanent bridge plug at +/-2465mKB

Kill well, pull pump and rods

RU pressure truck and PT BP to 7 mPa

Cap with 8 linear meters of cement on top of plug

MORU service rig

Kill well, pull pump and rods

RU tubing inspection equipment, pull and inspect 73.0mm tubing

MORU Wireline unit and set permanent bridge plug at +/-2465mKB

RU pressure truck and PT BP to 7 mPa

Cap with 8 linear meters of cement on top of plug

Swab well down to +/-1060mKB

MU and RIH with casing guns and perforate zone of interest from 1035.0 - 1037.0 mKB and 1043.0 to 1046.0 mKB

TorF: Typically the casing is swabbed prior to performing a thru-tubing perf job

False

If you are swabbing the casing, it means that there is no tubing in the well, and so therefore the perf job will not be thru-tubing

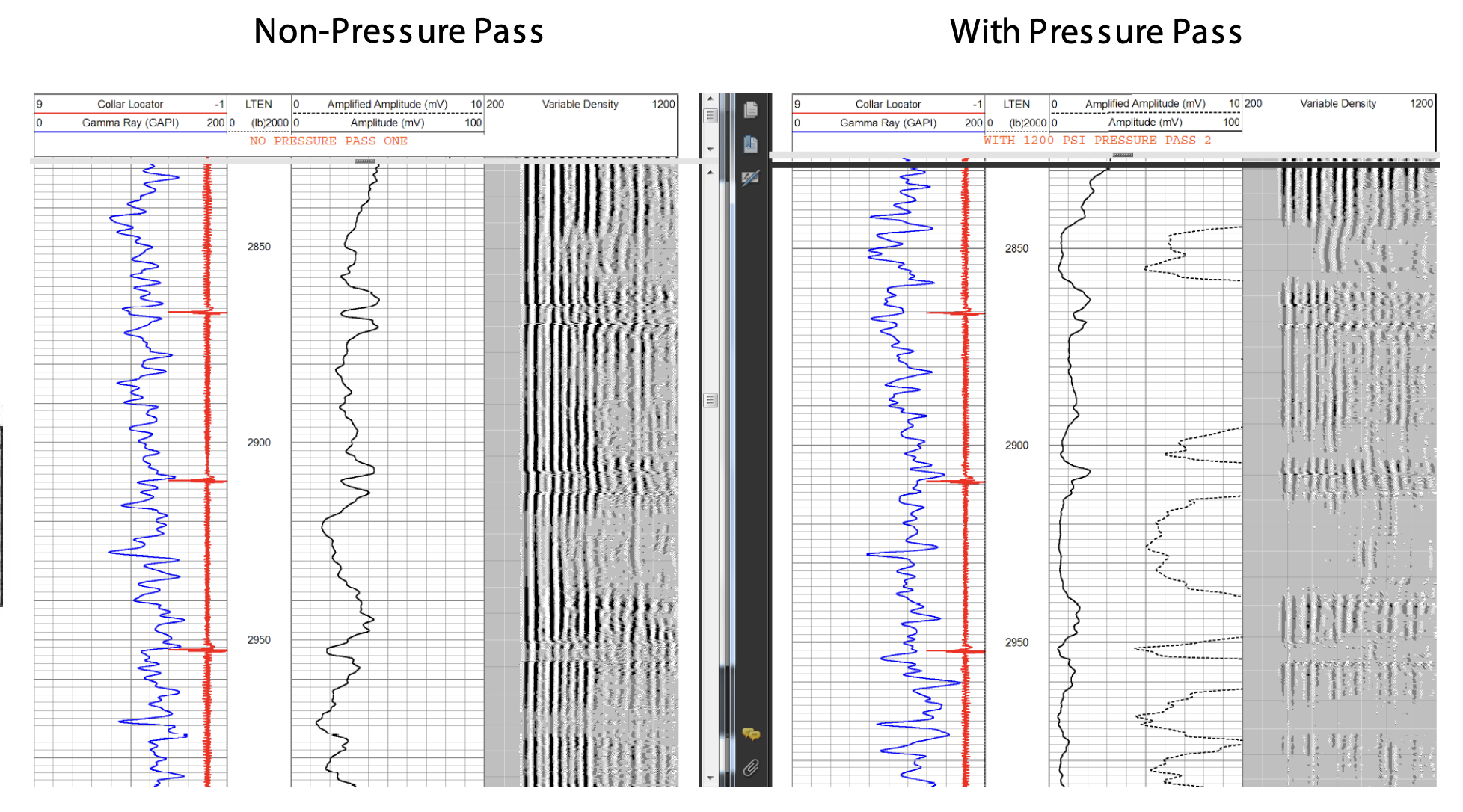

Your CBL is showing free pipe, and now you must decide whether or not to order a remedial cement squeeze. But as a SAIT student you know that a micro annulus (no squeeze required) can often be misinterpreted as free pipe (squeeze required). How would you decide whether or not to do a squeeze?

Perform a pressure pass

Pump fluid into the casing to increase internal pressure

The casing expands slightly

This compresses the microannulus, forcing the casing into better contact with the cement.

Run the CBL again while the pressure is applied

If CBL shows good casing-to-cement bond you have confirmed a micro annulus, and not free pipe

confirmation of a micro annulus means no remedial squeeze is needed, whereas with free pipe, a remedial squeeze would be required

How is a micro annulus different than free pipe?

Indicate the top of cement

Free pipe

Which of the following could be used for ram-to-ram pipe injection?

a) Service rig

b) Wireline unit

c) Coiled tubing unit

a) Service rig

ram-to-ram pipe injection → it’s a snubbing operation → could be a rig-assist snubbing operation → therefore, answer is service rig

neither wireline or CT use ram-to-ram pipe injection

Which type of conveyance would be used to perform open hole logging?

a) slickline

b) coiled tubing

c) pump-down

d) e-line

d) e-line

for open-hole logging specifically, you want to have real-time transmission, so slickline is not used

slickline could be used to run memory logs for cased-hole logging

Which operation unit would typically use a crane?

a) wireline

b) service rig

c) coiled tubing

c) coiled tubing

Uses a crane to hoist the injector head

On a wireline unit, where would the top sheave be connected?

On top of the lubricator

wireline passes over the top sheave, through the lubricator and into the well

What is the designated weak point on a wireline?

Cable heads

so that wireline will detach if tool gets stuck

What are the 3 main types of prep-work that must be done before a perf job?

Determine the interval to perforate.

Based on log parameters, relation to zone top, g/o & o/w interfaces

Determine the type of perforating gun to run.

Retrievable, expendable, shots/m, phasing

Estimate the reservoir pressure and corresponding fluid level to have in the wellbore to allow the well to be perforated slightly underbalanced

Which type of casing inspection logging tool could be used to identify external corrosion?

a) caliper

b) acoustic tools

c) ultrasonic tools

c) ultrasonic tools

can measure internal wear/corrosion directly - while also measuring wall thickness

therefore, external wear/corrosion can be inferred if there is a reduction in wall thickness at point x while there is also no indication of internal wear/corrosion at x

TorF: Downhole imaging tools are often used to detect problem areas downhole

False (operative word = detect)

expensive to run so not used to detect → used for inspection at a specific point after another type of tool detects a problem area